Constraints

At present, there are two constraints that can be applied to Epoch setups - the Resource Levelling Allocation (RLA) constraint and the Solid Availability constraint.

RLA constraint

The RLA constraint is an advanced tool which optimises the allocation of primary equipment to solids based on production rates and availability. The use of the RLA constraint is highly encouraged as it will reduce schedule times overall.

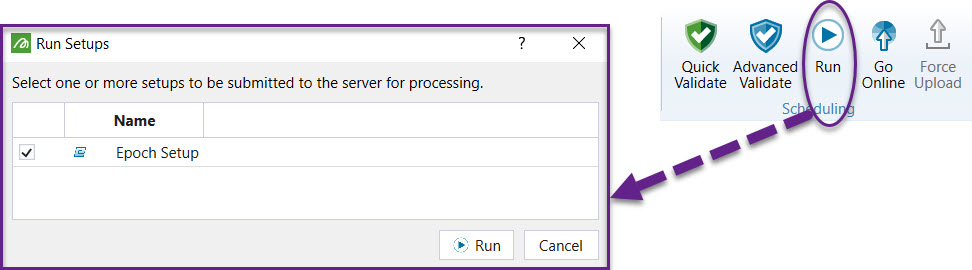

To use the constraint, first create an RLA constraint file by clicking the Run button in the Scheduling section of the Ribbon Control menu and then selecting the appropriate Epoch setup from the subsequent panel. The RLA Constraint file contains a record of allocations for pieces of equipment.

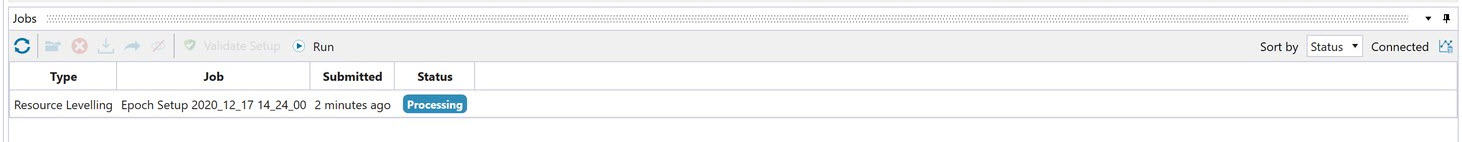

You can track the progress of the RLA constraint file in the Jobs Window.

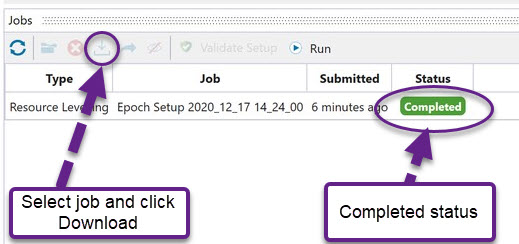

Once the job has the status Completed, it can be downloaded by clicking the Download icon.

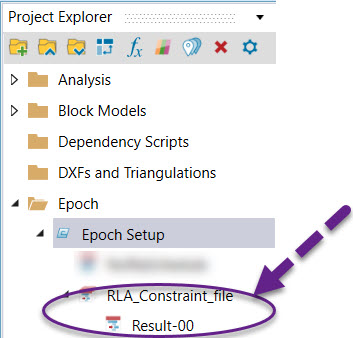

The RLA constraint file will appear in the Project Explorer.

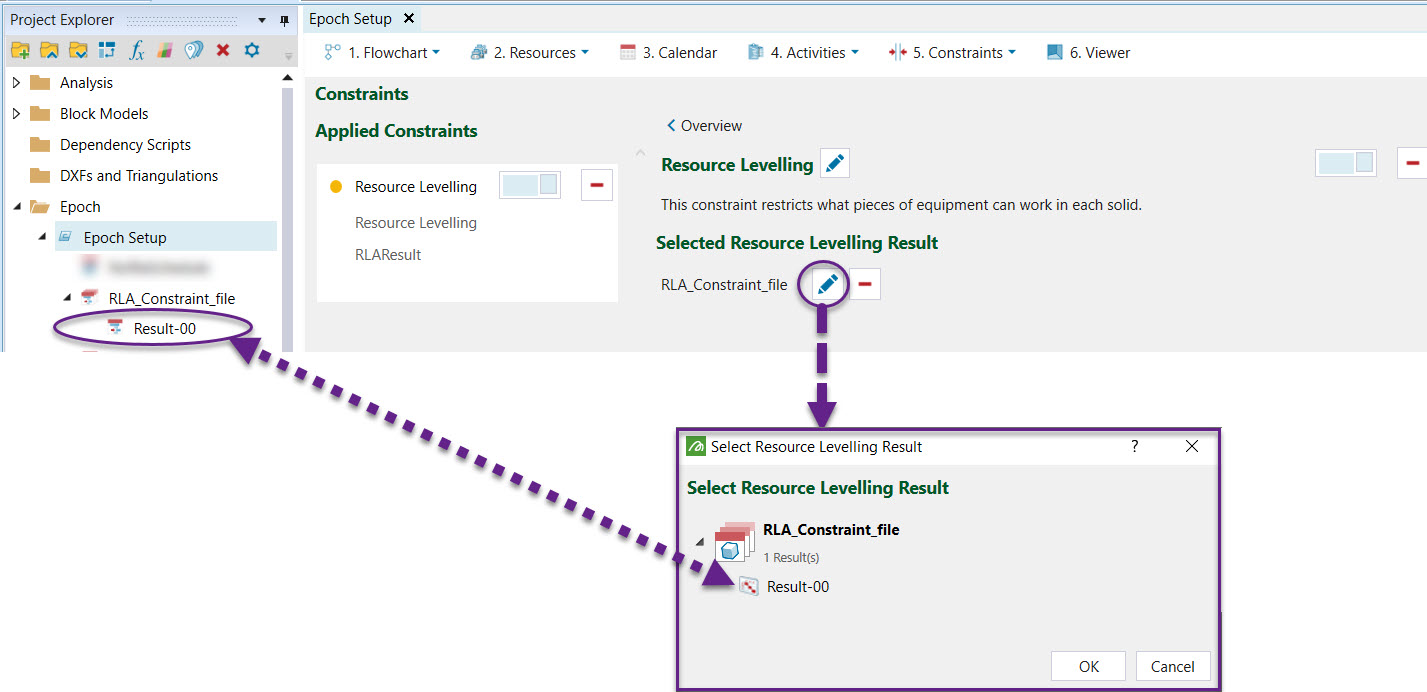

To view the results, open the Constraints-RLA tab and select the RLA Constraints file.

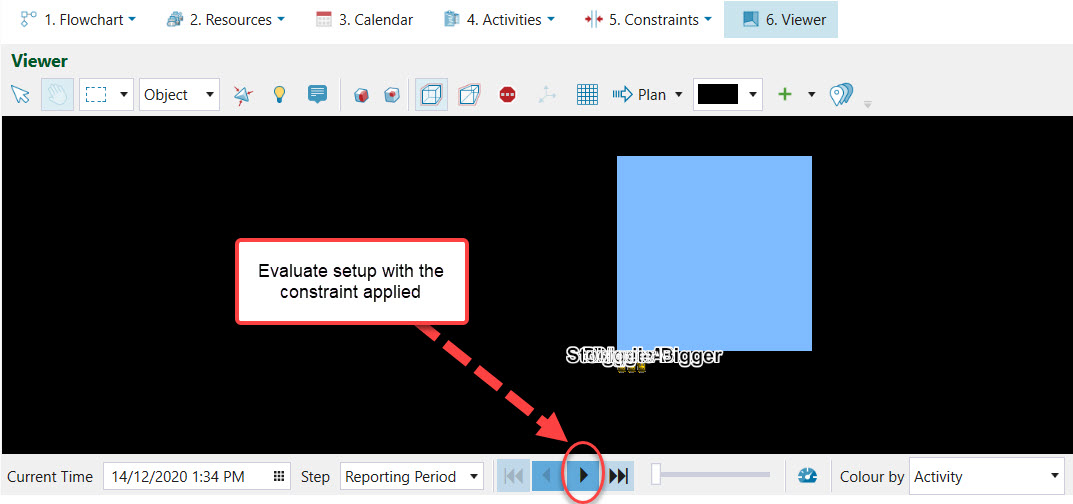

Once the constraint is added, results can be displayed by opening the Viewer tab and stepping forward using the client evaluator.

Solid Availability constraint

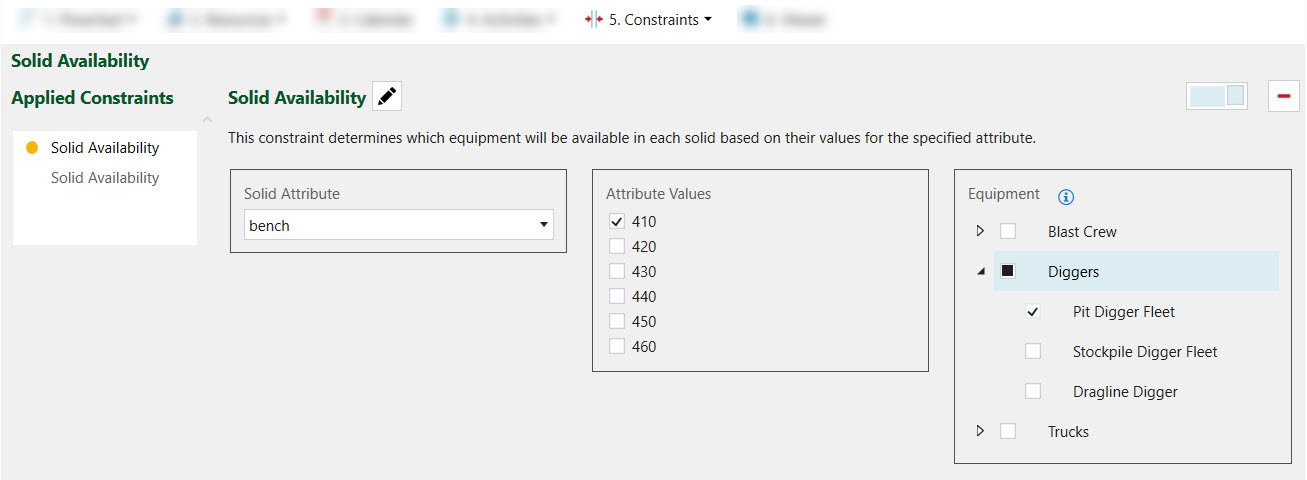

The Solid Availability constraint allows you to assign equipment to solids according to a specific solid attribute. The example below indicates that the equipment fleet Pit Digger Fleet has been assigned to work on solids with a bench (model variable) value of 410. No equipment from the Trucks resource has been allocated to bench 410 which means that ALL trucks are automatically allocated to bench 410.