Maximum Active Benches

It is advisable to limit the number of benches per stage mined at a given time to save costs and ensure safety.

Use the Maximum Active Benches constraint to restrict the number of benches in a stage being mined simultaneously in a single period.

Note: If you apply this constraint, you cannot apply the Stage Bench Turnover constraint.

To configure this constraint:

-

Click on a cell in the table which will belong to a particular pit, stage, and period.

-

Enter a value. This will represent the maximum number of active benches in that period. In the image below, we edit the maximum active benches in stage 8 of the pit Au_demo_new_phase in Period 1. This means that the maximum number of benches that can be mined at the same time in period 1 for stage 8 is 3. Note that this is different from limiting the total number of benches mined in a period. In other words, for this example, you can mine more than 3 benches in period 1 in total, just not at the same time.

After you generate a schedule, you can see if the constraint is being honoured in the Schedule Viewer or by exporting the schedule as a CSV file. To do this, right-click the schedule in the Data Explorer and select Export block data to CSV.

How you construct your spreadsheet will depend on the program you are using. Here is a basic overview of how to set it up:

-

Obtain a list of unique benches.

-

For each unique bench, find the rank of the first mined block.

-

For each unique bench, find the rank of the last mined block.

-

At each rank, for each bench, work out whether the rank falls between the values calculated in steps 2 and 3. If the rank falls between the values calculated at steps 2 and 3, that means that the bench is active. If the bench is active, you can add it to your tally.

-

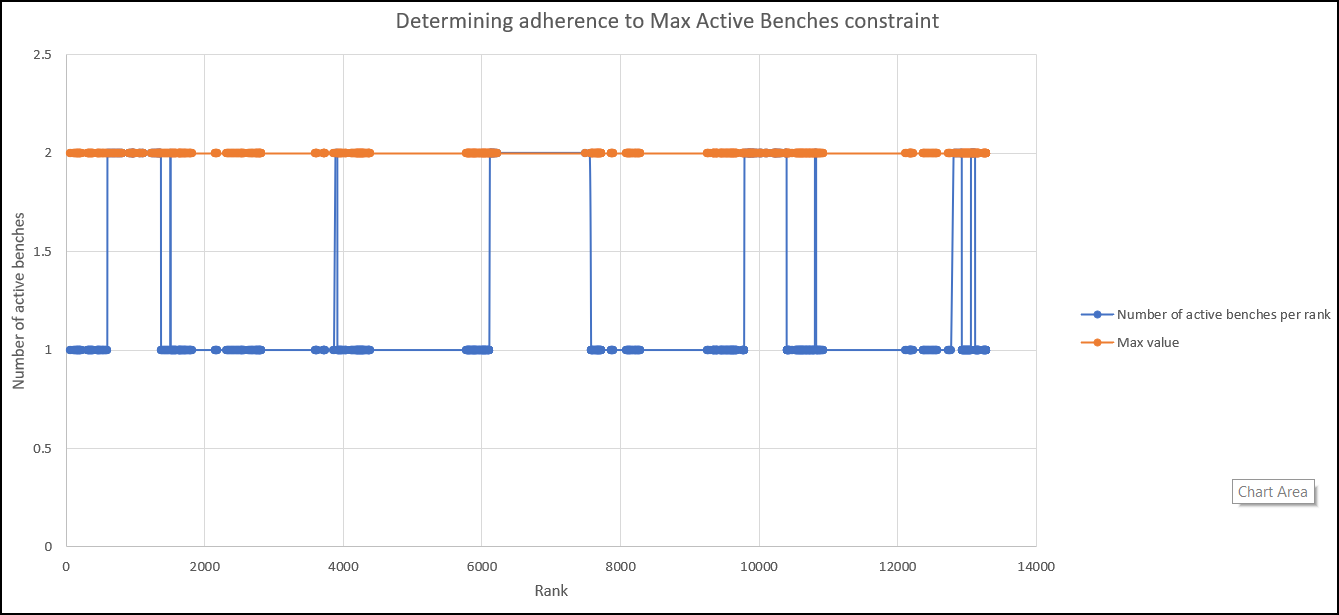

Graph the number of active benches calculated per rank. Your graph should look something like this.