Blend

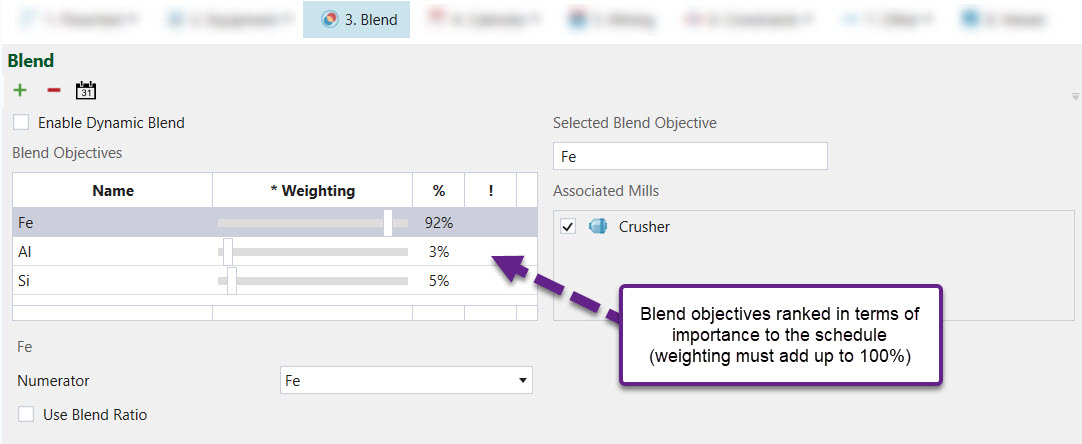

The Blend objective is used to determine the destination of an ore parcel per period based on its blend target.

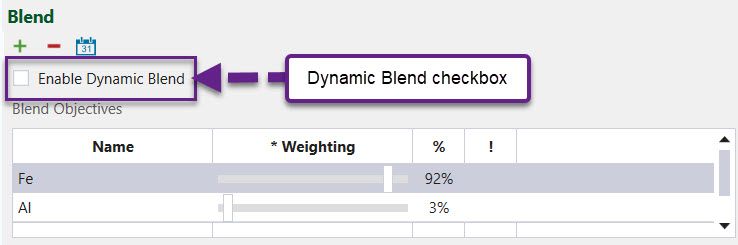

There are two modes of operation:

- Non-dynamic blend objective where material is sent to a stockpile and then recovered to meet the blend target. In this case, the definitions for all mills and stockpiles must be mutually exclusive.

- Dynamic blend objective where ore solids are sent to mill processes according to their grade in order to achieve a specific blend target. In this case, the definitions for mills and stockpiles can be mutually inclusive.

Non-dynamic blend objective

For the blend objective to work efficiently, there must be an issue where the ore body cannot be mined directly to the processor and needs to be stockpiled / blended to meet the desired grade specification. An example situation is when sections of the ore body do not meet the specified grade range unless blended with either higher grade or lower grade material. In this situation, the Evolution blend objective will firstly divert material intended to be stockpiled directly into the mill or secondly, reclaim from the stockpile if sufficient material is not available.

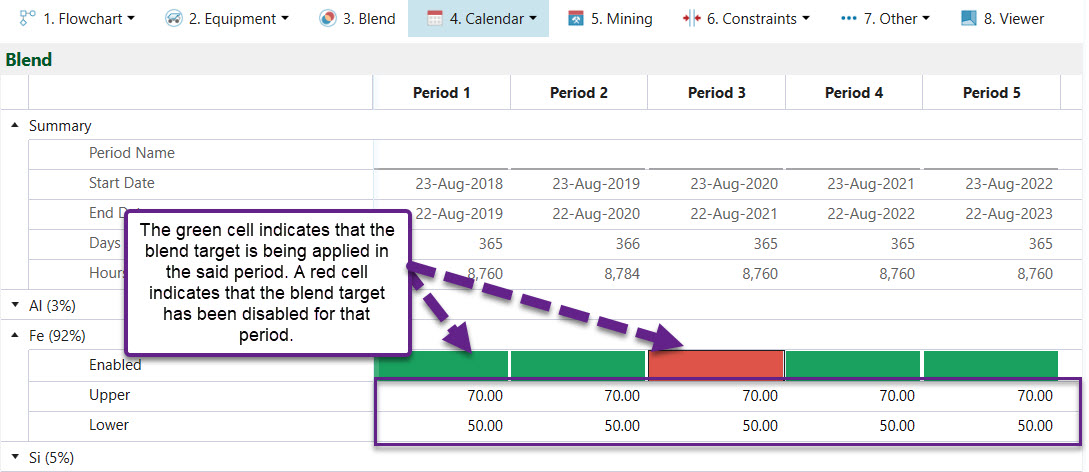

Within the Calendar > Blend tab, enter the upper and lower grade ranges targets for each blend objective per period.

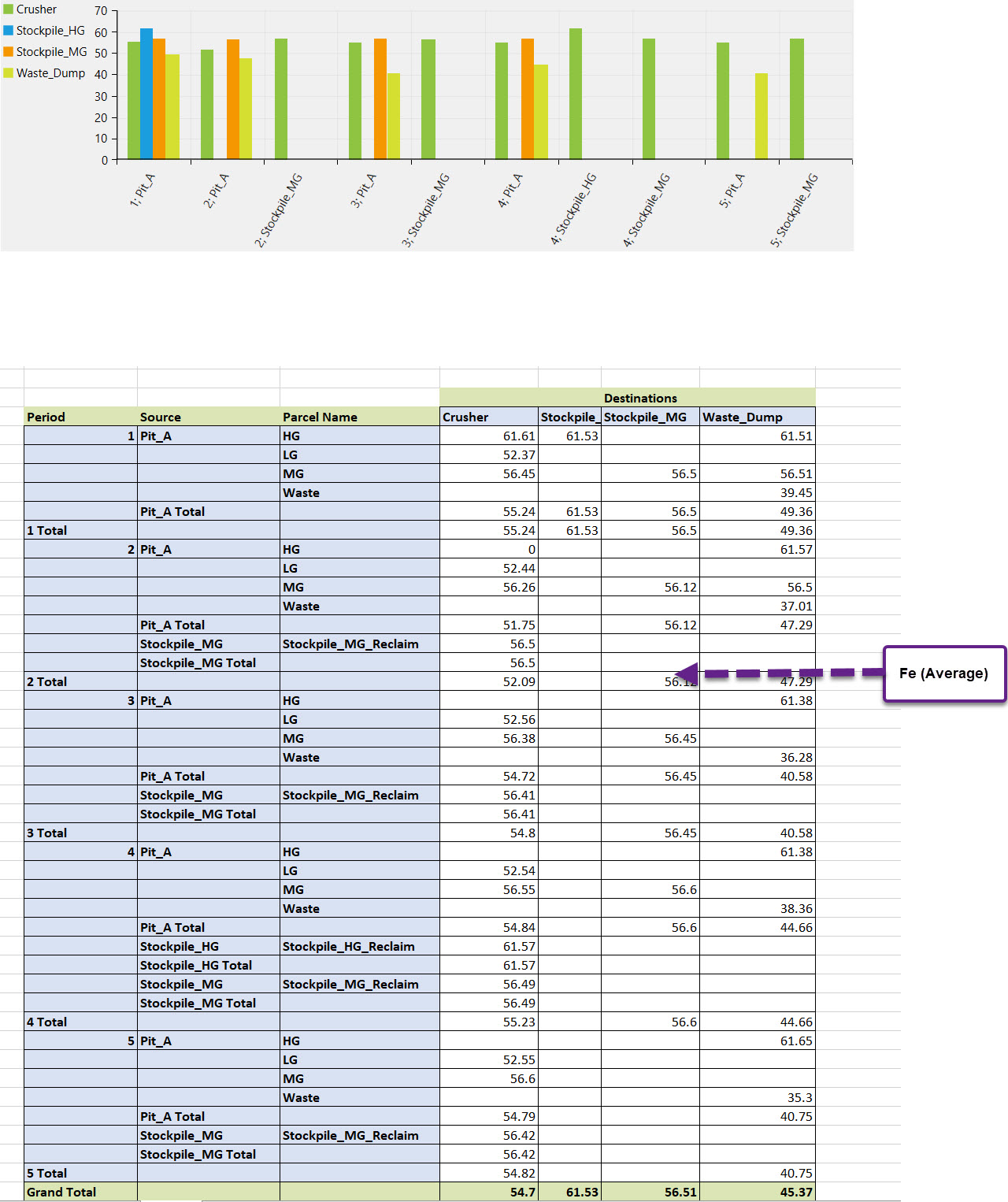

Once a schedule is generated, the results can be viewed in a pivot report.

Dynamic blend objective

For the dynamic blend objective, Evolution chooses to send material to either the stockpile or a mill, depending on which option best addresses the blend target.