Equipment

The Equipment objective includes the following tabs: Truck Types, Max Speed, Fleet Code, Parcel Truck Payload, Parcel Digger Truck Productivity, Hour Stamping, Equipment Wait Times, Advanced Options and Calendar.

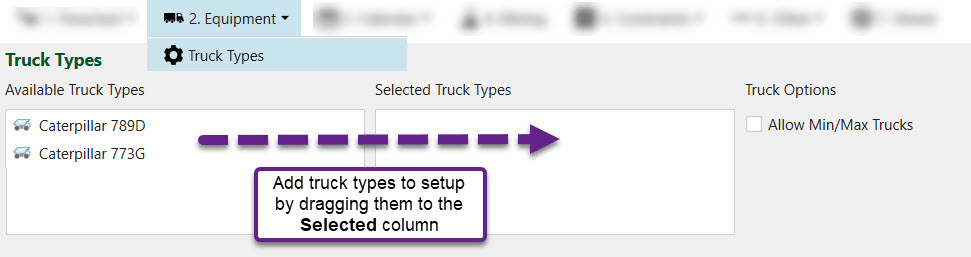

Truck Types

The Truck Types tab is used to add truck types within the project to the setup.

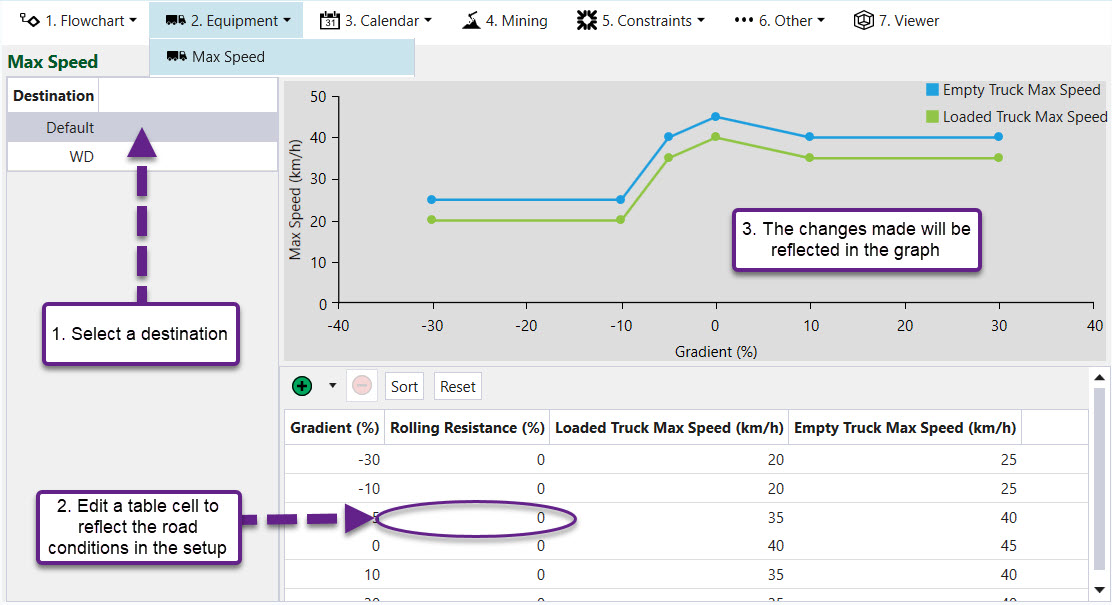

Max Speed

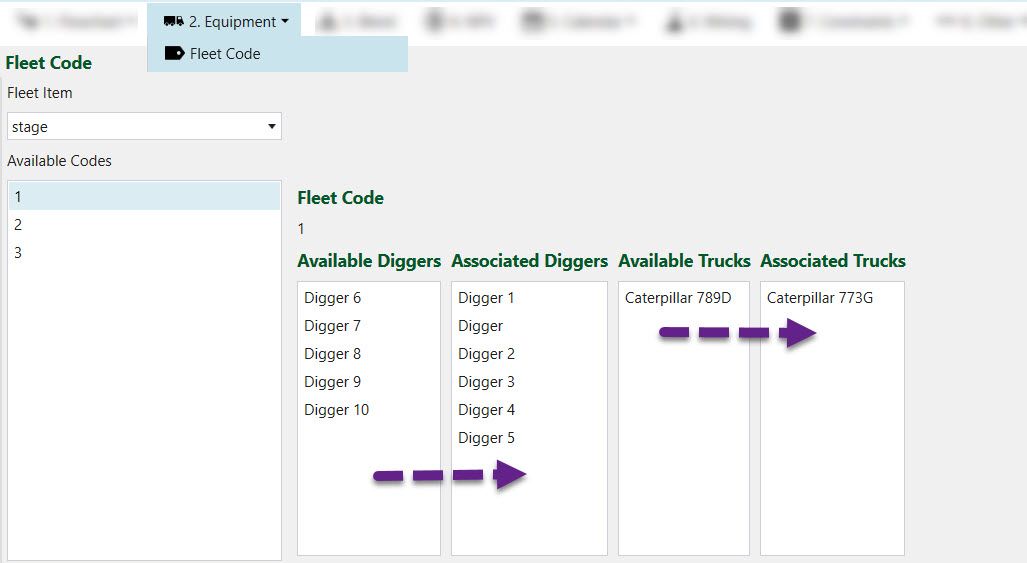

Fleet Code

This is an integer code in the model which will allow the engineer to map trucks to particular stages, lithologies or various combinations.

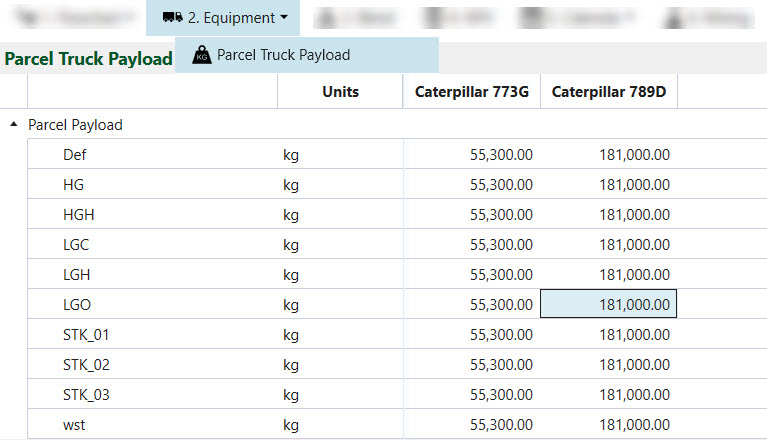

Parcel Truck Payload

The Parcel Truck Payload tab lets you assign the maximum amount of kilograms a truck can carry in a single trip per parcel.

Parcel Digger Truck Productivity

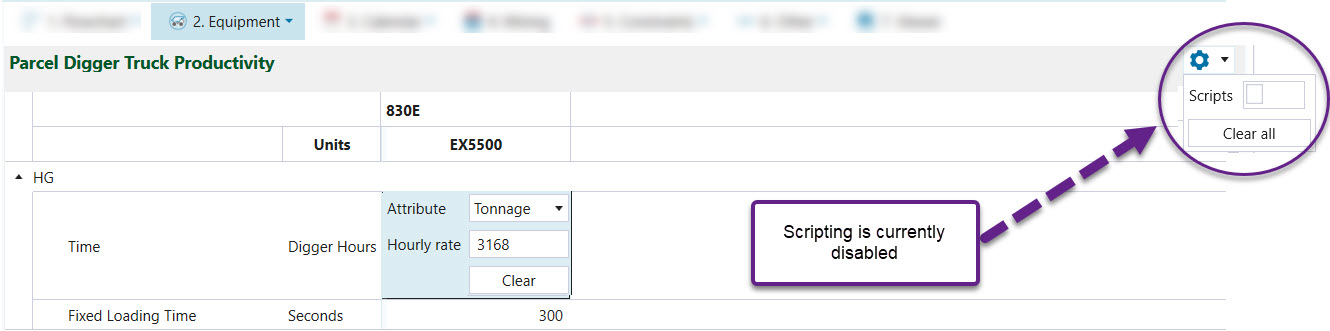

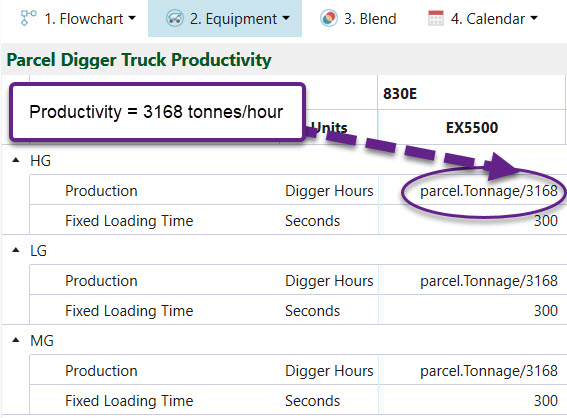

The Parcel Digger Truck Productivity tab is used to set the mining duration per parcel for each digger-truck combination. You can choose to either enter a rate which is converted to a duration or use scripting by enabling the scripting slider in the top right corner.

The following is an example of a production duration in digger hours if scripting is enabled:

Duration = parcel.totalmass/3168

where the denominator is a fixed rate in tonnes per digger hour.

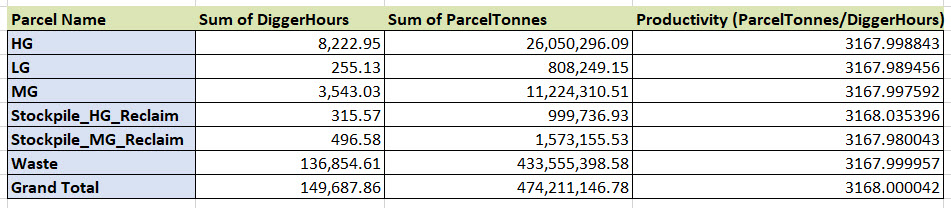

Once a schedule is created, the results can be checked using pivot reporting.

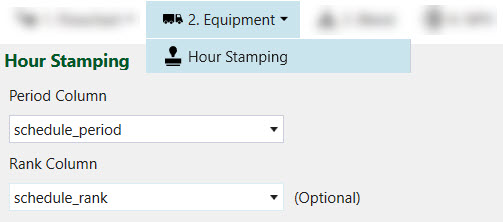

Hour Stamping

Origin allows the engineer to use a Period item in the model to replay an existing schedule. If another Evolution schedule is used, then you can also define a Rank as well.

Read more about stamping period and rank back to the model from an existing schedule, at the designated topic.

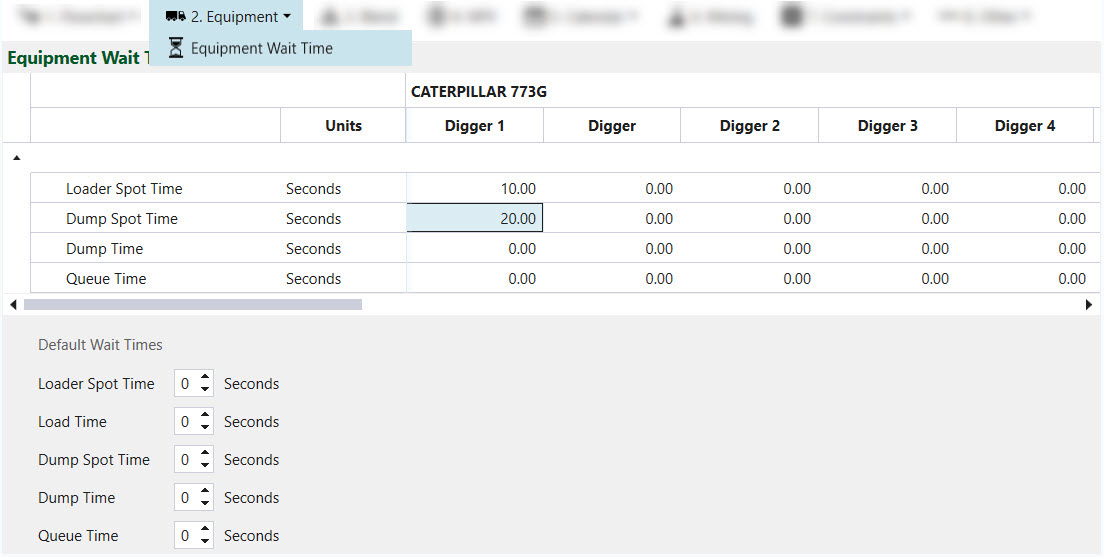

Equipment Wait Times

Equipment wait times are time frames required for the equipment to be set up.

- Loader spot time — Time for a truck to position itself under the digger.

- Load time — Time it takes for the digger to load the truck.

- Dump spot time — Time for a truck to position itself so that it can dump material.

- Dump time — The time it takes to dump material in a waste dump (typically 30 seconds).

- Queue time — The time it takes for a truck to wait for other trucks which are already loading/dumping.

Default times are back up values used in the case that the other values are either undefined or aren't available.

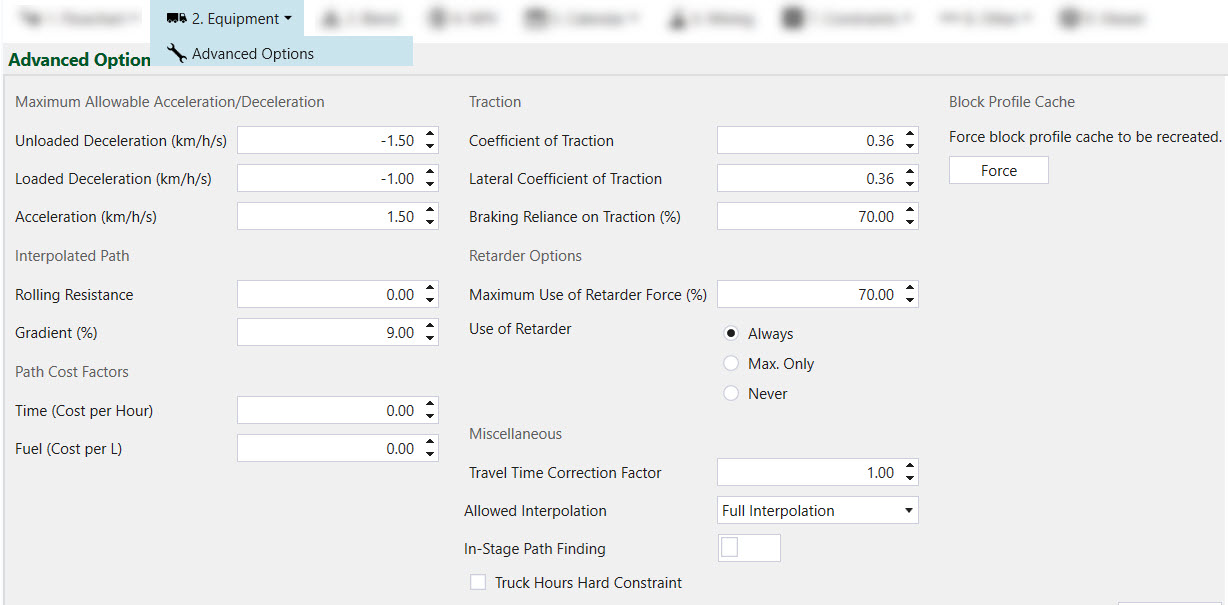

Advanced Options

The following parameters can be defined for Haulage based schedules:

Acceleration/Deceleration

Maximum Allowable Deceleration – Unloaded : This setting limits the deceleration of an empty truck to the specified number. This will override retard curve when necessary.

Maximum Allowable Deceleration – Loaded : This setting limits the deceleration of a loaded truck to the specified number. This will override retard curve when necessary.

Maximum Allowable Acceleration : This setting limits the acceleration of a truck. This will override the rimpull curve when necessary.

Traction

Coefficient of Traction : Factor describing the friction between truck tyres and ground.

Braking reliance on Traction : This factor proportionally increases distance required for breaking (represent reliance on traction coefficient to slow truck down).

Interpolated Path

Rolling Resistance: This factor specifies the rolling resistance from the current block that is mined to the start of the ramp.

Retarder Options

Maximum use of Retarder force: This setting helps to prevent overheating of the retarder on long steep descends. The lower this number the slower the truck will move when retarder is in use.

Use of Retarder: Currently Evolution defaults to “Always” and changing this setting does not impact calculations.

Miscellaneous

Travel Time Correction Factor: This factor can be used to account for any additional factors impacting travel time. A factor larger than 1 will increase travel time and vice versa.

Path Cost Factors

Costs can be assigned per hour (path time cost per hour) or per litre of fuel used (path fuel cost per litre).

Calendar

The following is a table of calculated fields in the Calendar > Equipment sub-tab.

| Field | Equation |

| Calendar Time (CT) | |

| Lost Time (LT) | You provide this value. |

| Available Time (AT) |

|

| Availability (%) |

|

| Utilisation Factor (UF) | You provide this value. |

| Utilised Time (UT) |

|

| Utilisation |

|

| Operating Efficiency (OEF) | You provide this value. |

| Effective Utilisation (EU) |

|

| Total Haulage Hours (THH) |

|

| Seasonality Factor (SF) | You provide this value. |

| Seasonally Adjusted Haulage Hours (SHH) |

|

| Seasonally Adjusted Utilisation (SU) |

|

| Operating Time (OT) |

|

| Seasonally Adjusted Operating Time (SOT) |

|