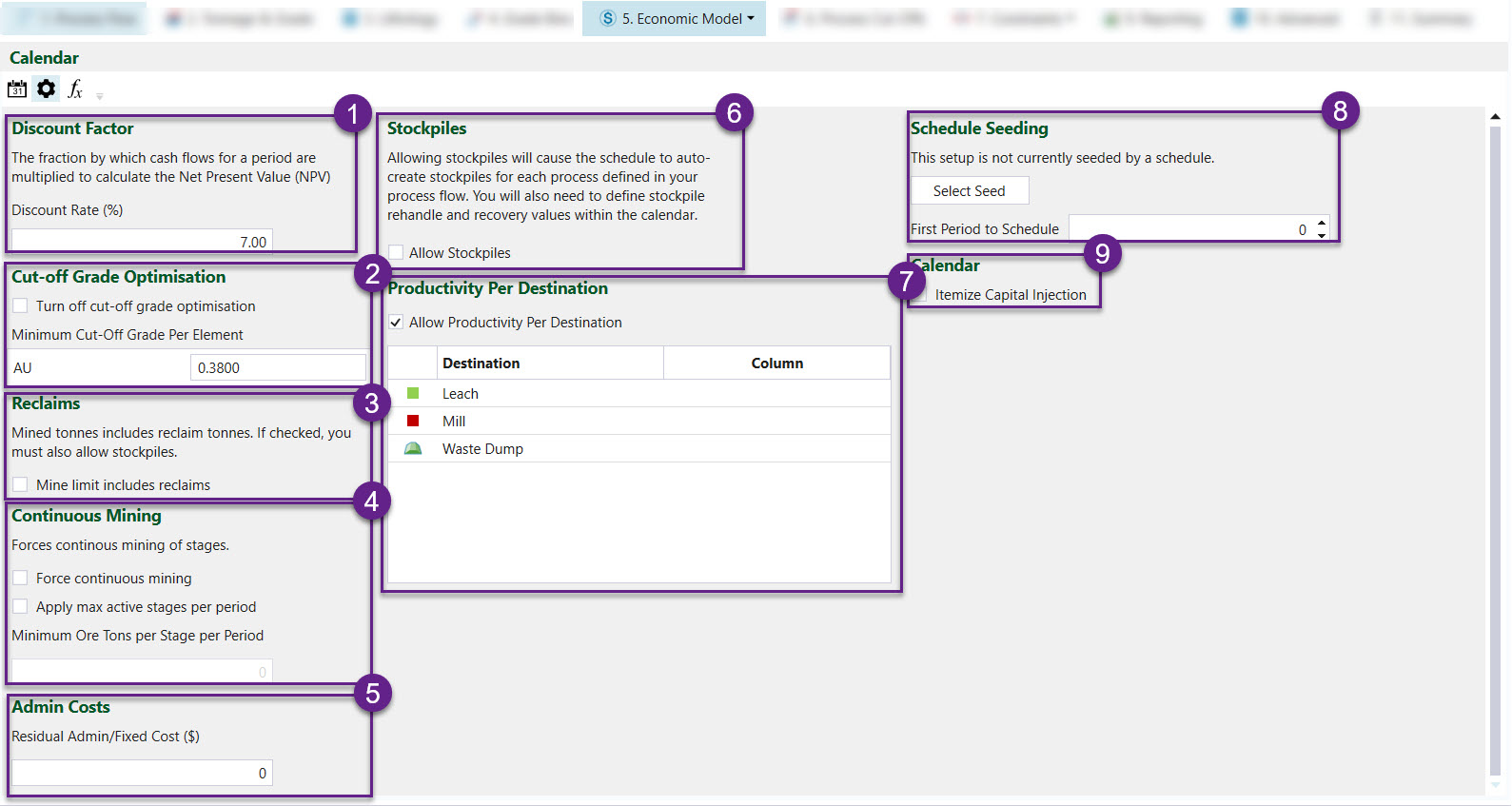

Configuration

Information in the Configuration tab is used to miscellaneous. There are nine sections:

- Discount rate

- Cut-off grade optimisation

- Reclaims

- Continuous Mining

- Admin Costs

- Stockpiles

- Productivity per destination

- Schedule seeding

- Itemised Capital Injection

Discount rate

The Discount Rate(%) is used to convert future cashflows to a present value.

Cut-off grade optimisation

Strategy optimises mining sequences in two separate modules: cut-off grade and NPV. You can turn off cut-off grade optimisation using the Turn off cut-off grade optimisation checkbox included in this tab.

If cut-off grade optimisation is selected for the setup, you can specify the minimum grade of the output material per element.

Reclaims

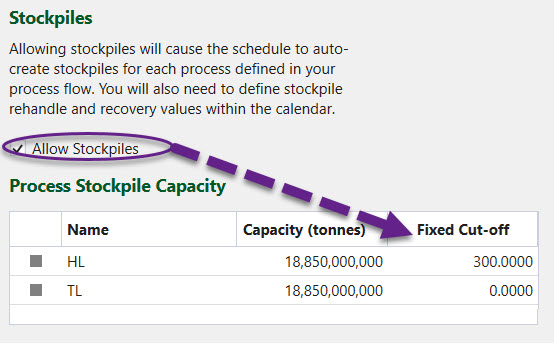

Reclaim tonnes can be included in the final mined tonnes of a schedule. If this option is selected, the setup must include stockpiles. Stockpiles can be added in the Process Flow tab or in the Stockpiles section of the current tab (6).

Continuous Mining

This option allows the you to enforce the continuous mining of stages. The output of this restriction can be checked in the Stages tab in the final schedule report.

Another function in this section is to specify the maximum amount of stages that can be mined per period using the Apply max active stages per period checkbox. If this checkbox is selected, then specify the minimum ore tonnes that can be mined per stage per period.

Admin Costs

You can define the amount of general and administrative costs per period required to run an operation in the Economic Model > Calendar > Calendar tab. However, in order to define admin costs per period, first define a residual admin/fixed cost in the Configuration sub-tab. This cost will replace the admin cost provided in the Calendar tab when pit material is depleted and the setup enters reclaim mode (the result can be seen in the schedule report).

In order to enter reclaim only mode, the setup needs to have stockpiles with at least the same capacity as the process. Stockpiles can be added either as overflow in the Configuration tab or as components in the Process Flow tab.

Stockpiles

If you want to create overflow stockpiles adjacent to each process, they can tick this checkbox. If this is the case, you will need to define a capacity for each stockpile under the Process Stockpile Capacity section.

Productivity per Destination

Evolution provides the option of modeling productivity hours as part of strategic optimisation. If this checkbox is selected, each destination needs to be assigned a productivity variable provided by the block model included in the setup. Note: For this section to be included, the setup must have a waste dump, which is added in the Process Flow tab.

Schedule seeding

You can derive schedules from previously developed schedules and a Seed Start Period using Evolution’s seeding mechanism.

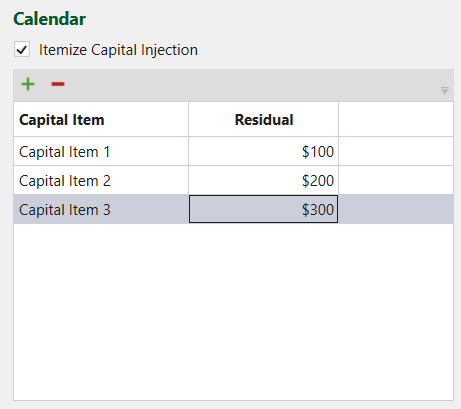

Itemised Capital Injection

A mining operation may have many types of capital. The Itemised Capital Injection option allows you to break this information down by specifying them as shown below. The items will be added to the Calendar where you have the option of specifying an operating cost per period.

For each type of capital, define the amount per period. The amounts are automatically summed and consolidated in the Capital Injection line. Strategy will use only this consolidated line when calculating final cash flows.