Constraints

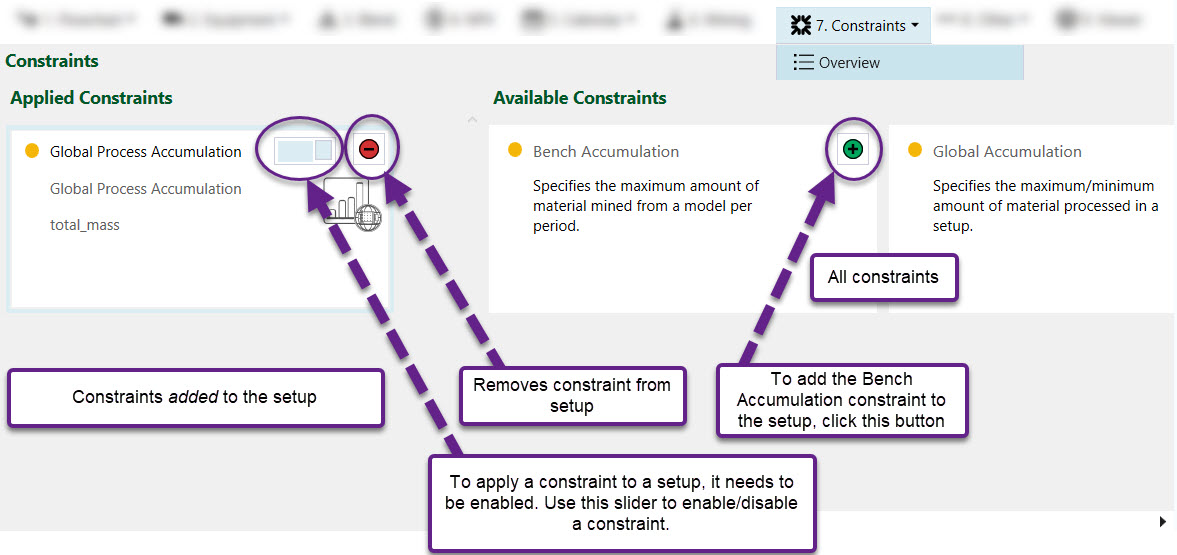

Constraints have been introduced into Evolution to provide another way to refine data.

The following table provides a description of each constraint available in Origin Solid setups. Constraints are classified as hard (the software must adhere to the constraint) or soft (the software aspires to meet that constraint). For more information on the constraint, click on the heading.

| Constraint | Hard/ Soft | Description |

| Bench Accumulation | H | Used to set the maximum/minimum amount that can be mined per bench per period. |

| Global Accumulation | H | Used to set a maximum/minimum volume or amount of tonnes that can be mined per period. Each period has an accumulation enabled checkbox. If the checkbox is enabled, a maximum/minimum limit is applied. If not, this means that an unlimited amount can be processed by all mills in that period. |

| Global Process Accumulation | H | Used to set a maximum/minimum volume or amount of tonnes that can be produced by all mills in a setup per period. Each period has an accumulation enabled checkbox. If the checkbox is enabled, a maximum/ minimum limit is applied. If not, this means that an unlimited amount can be processed by all mills in that period. |

| Model Accumulation | H | Used to define the maximum volume or amount of tonnes that can be mined per pit per period. |

| Parcel Waste Area Priority | H | Used to define the transfer of parcel material to waste areas in order of most preferred to least preferred. |

| Pit Region Availability | H | Used to set the availability of areas within a pit per period. Typical regions used would include bench or stage. |

| Pit Region to Waste Region | H | Maps a solid’s transfer to a specific location in a waste utility based on its own position within the pit. |

| Process Accumulation | H | Used to restrict material sent to a mill per period (tonnage or volume). |

| Sink Rate | H (approximate) | Used to calculate the mining duration per period, based on production rates defined by the user. |

| Stage Accumulation | H (approximate) | Used to restrict the amount of material (tonnage or volume) that is mined per stage in a pit per period. |

| Stage and Waste Utility Dependency | H | Used to send material to specific waste areas based on which stage they belong to. |

| Stage Availability | H | Flags the availability of stages for mining per period. |

| Stage Bench Turnover | H | Used to set the maximum number of benches that can be mined in each stage per period. |

| Stage Dependency | H | Used to define the order of stages mined. In other words, linking stage 1 to stage 2 in that order means that all of stage 1 needs to be mined before stage 2. |

| Stage Equipment | H | Maps equipment to specific stages in a pit. This constraint is useful when certain equipment are better suited to specific conditions such as rock types than others. |

| Stage Sink Rate | H (approximate) | Used to calculate the duration of mining per stage per period. |

| Stockpile Availability | H | Used to set when material can be sent to the stockpile on a periodic basis. |

| Stockpile Redirect Availability | H | Used to set when material can be reclaimed from a stockpile to a mill on a periodic basis. |

| Waste Area Availability | H | Used to set the availability of each waste area for waste dumping on a periodic basis. |

| Waste Area Dependency | H | Used to set the order in which areas in a waste utility should be used. In other words, if waste area 5 is linked to waste area 6, all of waste area 5 must be filled before waste area 6 can be used for transferring waste material. |

| Waste Area Rate of Rise | H | Used to limit the rate at which the height of an area within a waste dump can increase per period. |

| Waste Area Required Tonnage | H (approximate; within a solid) | Used to limit the mass of material transferred to a waste area per period. |