Calendar

The Calendar tab contains two tabs: Calendar and Configuration.

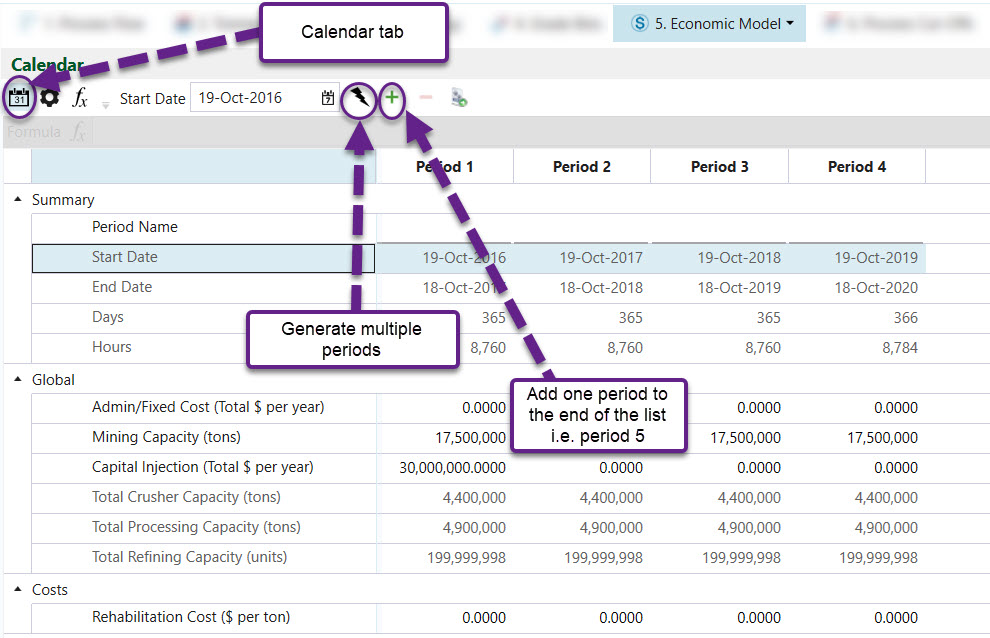

Calendar

The following parameters defined in the Economic Model > Calendar tab are used to calculate the NPV.

- Admin/Fixed Cost ($ per year) — Enter the cost occurring while the mine is in operations.

- Mining Capacity (tonnes per year) — Enter a practical mining upper limit that can be achieved.

- Capital Injection ($ per year) — Enter any up front or on-going capital requirements.

- Rehabilitation Cost (% per year) — Enter the Rehabilitation cost increase per period.

- Mining Cost Escalation (% per year) — Enter the mining cost increase per period.

- Crusher Capacity (tonnes per year) — Enter the crusher limit of the primary crusher.

- Capacity (tonnes per year) — Enter the upper limit of the processing plant. If the processing throughput is not yet known, each of the process nodes can have the same capacity as the crusher capacity, allowing you to determine the appropriate process feed. This input can be refined as each schedule scenario is performed.

- Processing Cost Escalation (% per year) — Enter the processing cost increase / decrease per period

- Refining Capacity (units per year) — Set the maximum units that should be produced to prevent either a market flood of the element, or a capacity limit relating to smelting or refining of the product.

- Selling Costs ($ per unit) — Enter the cost associated with selling or refining of the element. i.e. this could be a rail cost, shipping cost, or a refining cost.

- Price ($ per unit) — Enter the price per unit for the element.

- Rehandle Cost ($ per tonne) — Enter the cost per tonne to rehandle a tonne of material from stockpile to the mill.

- Rehandle Cost ($ per tonne) — Enter the cost per tonne to rehandle a tonne of material from stockpile to the mill.

- Maximum Reclaim — Enter the maximum reclaim percentage of an ore when recovered from stockpile. This can be 100% recovery if aiming for mining only from stockpiles or can be zero resulting in mining only from pits. Note that the maximum reclaim is set as a percentage of the crusher capacity not the process capacity.

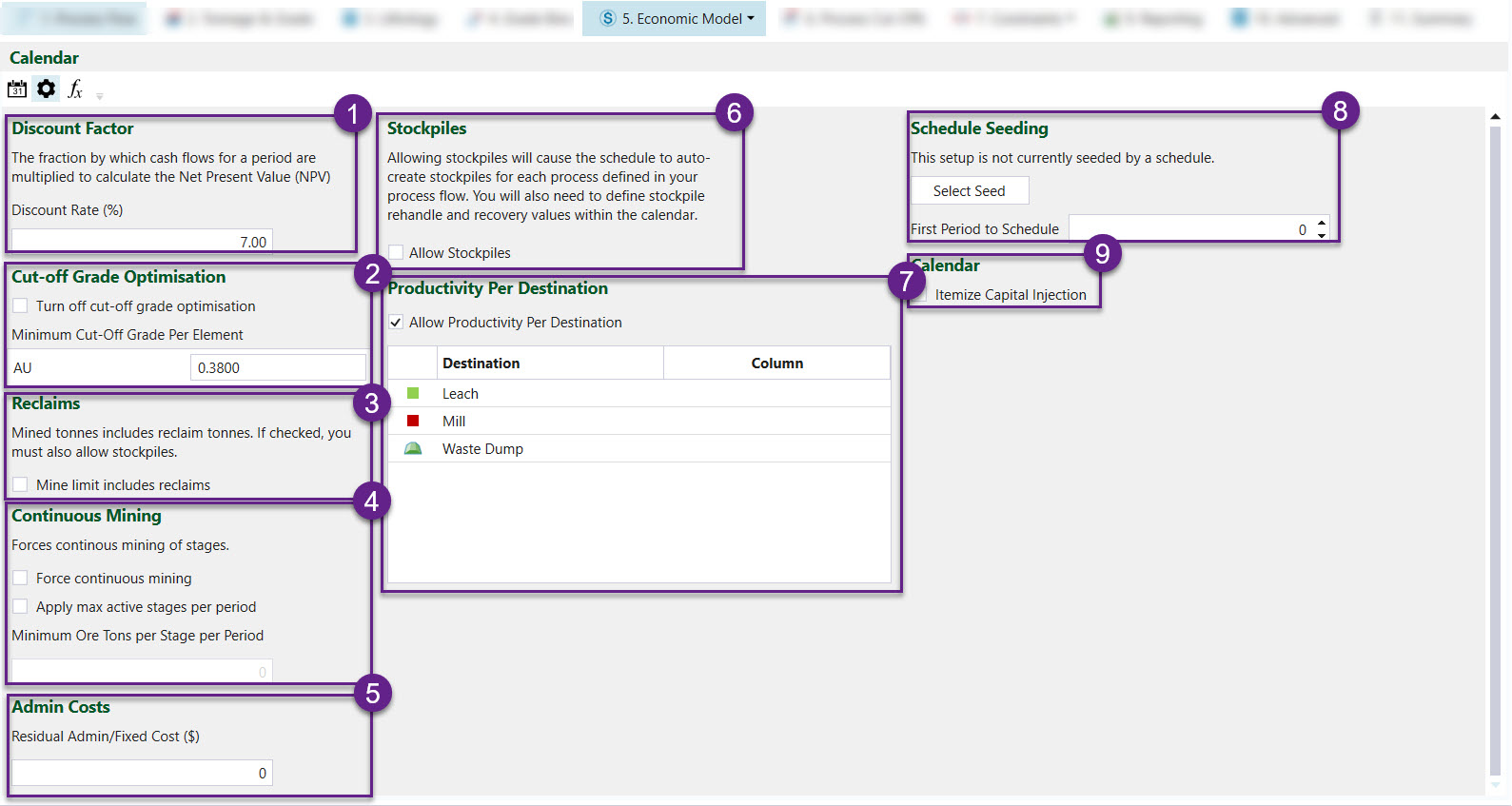

Configuration

There are nine sections you can configure:

- Discount rate

- Cut-off grade optimisation

- Reclaims

- Continuous Mining

- Admin Costs

- Stockpiles

- Productivity per destination

- Schedule seeding

- Itemised Capital Injection

Discount rate

The Discount Rate(%) is used to convert future cashflows to a present value.

Cut-off grade optimisation

Strategy optimises mining sequences in two separate modules: cut-off grade and NPV. You can turn off cut-off grade optimisation using the Turn off cut-off grade optimisation checkbox included in this tab.

If cut-off grade optimisation is selected for the setup, you can specify the minimum grade of the output material per element.

Reclaims

Reclaim tonnes can be included in the final mined tonnes of a schedule. If this option is selected, the setup must include stockpiles. Stockpiles can be added in the Process Flow tab or in the Stockpiles section of the current tab (6).

Continuous Mining

The Continuous Mining section allows you to set two continuous mining options. Continuous mining refers to when all the stages are mined continuously in a schedule. You can set the following options:

-

Force continuous mining — Select this checkbox to force Evolution to create a schedule where all of the stages are mined continuously. More specifically, Evolution will not open a new stage unless it is impossible to mine from an already open stage. You can check the output of this restriction in the Stages tab in the final schedule report.

Note:Evolution will only enforce this option if all of the setup constraints are satisfied. If a constraint is broken when the stages are mined continuously, Evolution may open a new stage.

For example, say you set a constraint in which Evolution can only mine a proportion of the benches in a stage per period. If the schedule achieves this number before the end of the period, Evolution will open a new stage, despite not having finished mining the first stage.

-

Apply max active stages per period — Select this checkbox to force Evolution to mine the maximum number of stages per period, provided the minimum ore tonnes is met for each stage. You can enter the desired value into the Minimum Ore tonnes per Stage per Period field to specify the minimum ore tonnes per stage per period.

Admin Costs

You can define the amount of general and administrative costs per period required to run an operation in the Economic Model > Calendar > Calendar tab. However, in order to define admin costs per period, first define a residual admin/fixed cost in the Configuration sub-tab. This cost will replace the admin cost provided in the Calendar tab when pit material is depleted and the setup enters reclaim mode (the result can be seen in the schedule report).

In order to enter reclaim only mode, the setup needs to have stockpiles with at least the same capacity as the process. Stockpiles can be added either as overflow in the Configuration tab or as components in the Process Flow tab.

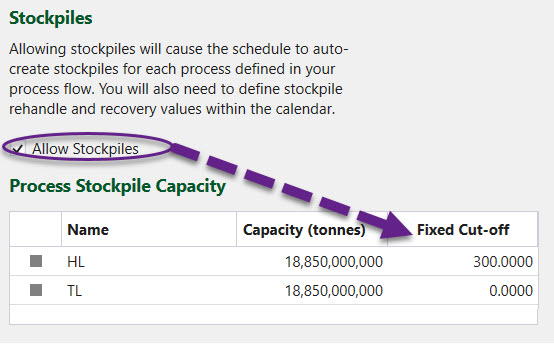

Stockpiles

If you want to create overflow stockpiles adjacent to each process, they can tick this checkbox. If this is the case, you will need to define a capacity for each stockpile under the Process Stockpile Capacity section.

Productivity per Destination

Evolution provides the option of modeling productivity hours as part of strategic optimisation. If this checkbox is selected, each destination needs to be assigned a productivity variable provided by the block model included in the setup. Note: For this section to be included, the setup must have a waste dump, which is added in the Process Flow tab.

Schedule seeding

You can derive schedules from previously developed schedules and a Seed Start Period using Evolution’s seeding mechanism.

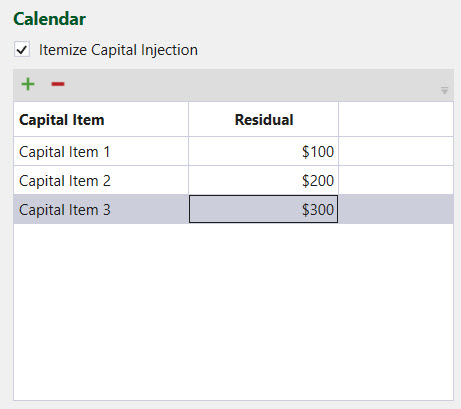

Itemised Capital Injection

A mining operation may have many types of capital. The Itemised Capital Injection option allows you to break this information down by specifying them as shown below. The items will be added to the Calendar where you have the option of specifying an operating cost per period.

For each type of capital, define the amount per period. The amounts are automatically summed and consolidated in the Capital Injection line. Strategy will use only this consolidated line when calculating final cash flows.