Configuration

The Configuration tab is used to define static parameters for each process flow component added to the setup.

Pit (solid)

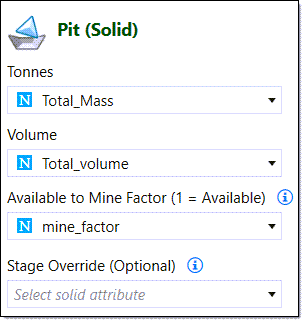

The Configuration tab contains three required fields:

-

Tonnes — Provide the attribute which best represents the maximum tonnes. The total tonnes for every solid in the model must equal the sum of all parcel tonnages and volumes set in the Flowchart > Parcel Settings tab.

-

Volume — Provide the attribute which best represents the maximum volume. The total volume for every solid in the model must equal the sum of all parcel tonnages and volumes set in the Flowchart > Parcel Settings tab.

-

Available to Mine Factor — Provide an attribute from the imported pit that best represents the proportion of a solid which is accessible for mining. An availability of on means that the entire solid can be mined. On the other hand, an availability of zero means that no part of the solid can be mined.

Optionally, you can change the pit stage by selecting a new attribute from the Stage Override drop-down. This allows you to have different stage attributes for setups with the same pit models.

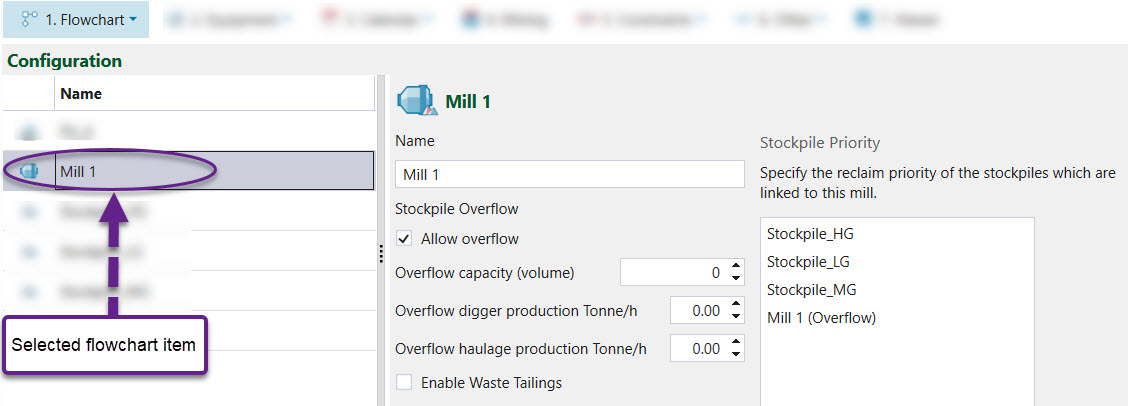

Mill

A mill is a piece of equipment which breaks down material into smaller pieces. In Evolution, the use of a mill is simplified to processing ore material.

The Configuration tab is mainly used to define the following:

-

Allow overflow — Check this to create a stockpile next to the mill (overflow).

-

Overflow capacity (volume) — Enter the volumetric capacity of the overflow.

-

Overflow digger production (tonnes/h) — Enter the rate at which a digger can reclaim from the overflow.

-

Overflow haulage production (tonnes/h) — Enter the rate at which a truck delivers material from the overflow to the mill.

-

Enable Waste Tailings — Included for mines with very low grade material being produced by the mill. In such an example, material that gets sent to the mill, is split between the mill and the waste dump but overwhelmingly in favour of the waste dump. Check this checkbox if you want Evolution to ignore the split behaviour and act as if everything has been sent to the waste dump.

-

Stockpile Priority — Provide the stockpile order by dragging and dropping list items. Material is sent first to the stockpile which appears first in the list. Evolution automatically gives the overflow stockpile first priority.

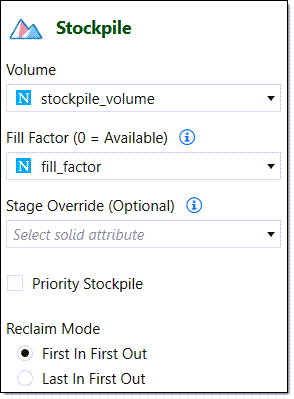

Stockpile (solid)

A reserve stockpile is a destination with geometrical information used to store low to mid grade material in the short term. To achieve the desired grade, once the mill is ready to accept more material, material from the stockpile can be sent to the mill. This is called reclaiming. A stockpile (solid), similar to a pit (solid) model is a set of triangulations with attributes. It is only used in equipment setups.

In the Configuration tab, there are four fields that need to be set:

-

Volume — Provide an attribute from the imported reserve stockpile model which represents maximum volume for each unit of space (solid) within the model. An attribute for Volume must be provided for the configuration of the reserve stockpile model to be successful.

-

Fill factor — Supply an attribute from the imported stockpile that best represents the proportion of the stockpile that cannot be used for storage. A fill factor of one means that the entire solid cannot be used for storing material. On the other hand, a fill factor of zero means that material can be stored in any part of that space.

-

Priority Stockpile — Check this checkbox if you would like to make this particular stockpile the first stockpile to send material to. If this checkbox is selected, the Priority Stockpile Target (tonnes) needs to be set per period in the Calendar > Calendar tab.

-

Reclaim mode — Select the reclaim mode from the following options:

-

FIFO (First In First Out) where the first solid sent to the stockpile, is the first solid to be reclaimed.

-

LIFO (Last In First Out) where the last solid sent to the stockpile, is the first solid to be reclaimed.

-

Optionally, you can change the stockpile stage by selecting a new attribute from the Stage Override drop-down. This allows you to have different stage attributes for setups with the same stockpile models.

Virtual waste dump

Virtual waste dumps contain no geometrical data and are included when the exact location of waste stored is not critical. The static parameters defined include name and capacity.

Reserve waste dump

A reserve waste dump is a waste dump with clearly defined geometry. In an equipment setup, this is necessary for transporting waste to specific locations within the waste dump. When the exact location of wasted material is not required, a virtual waste dump is used instead (see virtual waste dumps).

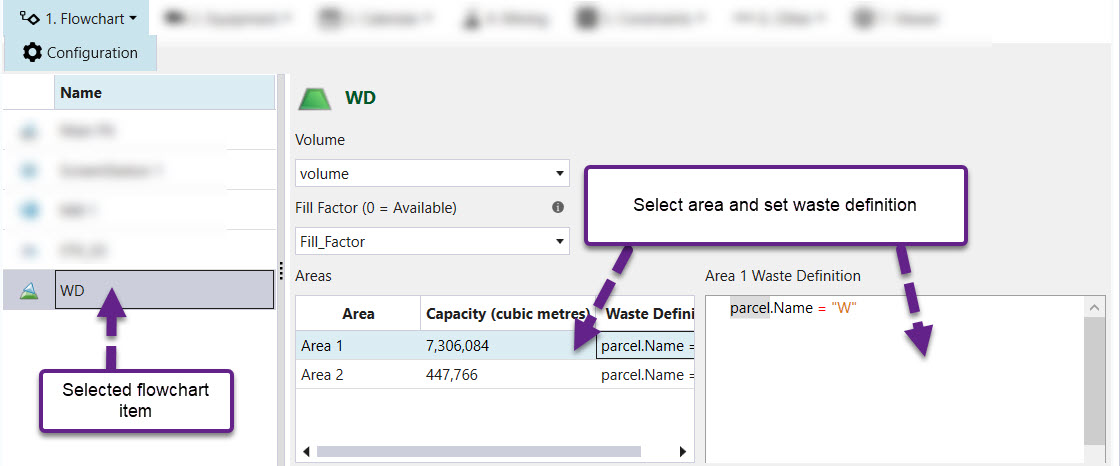

To configure a reserve waste dump, set the following fields:

-

Volume — Select the attribute from the imported reserve waste utility, that best represents the maximum volume for each unit of space within the reserve waste utility.

-

Fill Factor — Select the attribute from the imported reserve waste utility, that best represents the fill factor for each unit of space within the reserve waste utility.

-

Areas — Provide a waste definition for each area defined in the imported reserve waste utility. This definition determines the type of material that the waste utility can accept. For example, if the waste definition for Area 1 is set to the following:

parcel.name = "Waste Parcel"

This means that only the proportion of material that is classified as “Waste Parcel” can be sent to Area 1 in the reserve waste utility. If the waste definition is left blank, this means that all material can be sent to the specified area.

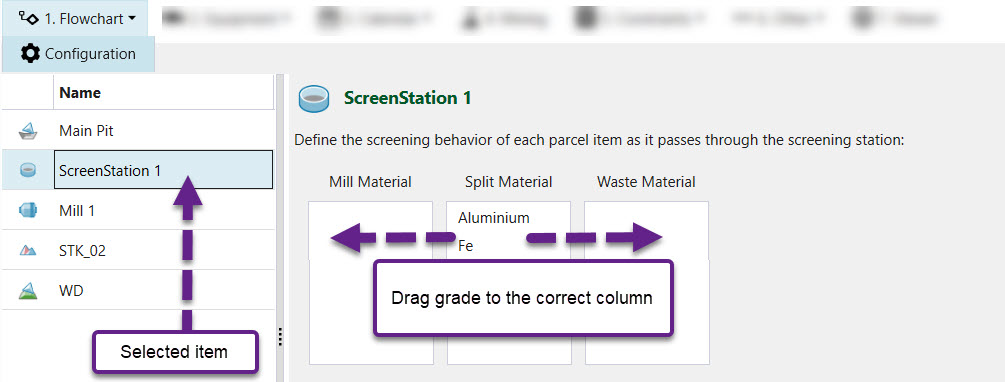

Screening station

Screening stations are used to separate material into product and waste. Split material can go to either product or waste streams.

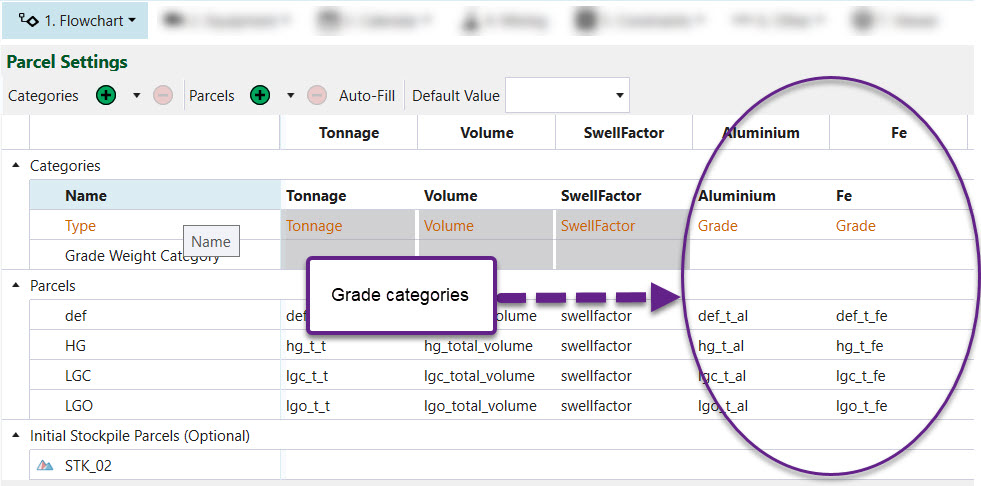

To use this tab, grade categories and a rejection factor need to be defined in the Flowchart > Parcel Settings tab. A rejection factor is a value between 0.0 and 1.0 and defines how much material isn't processed by the screen station.