Screening stations

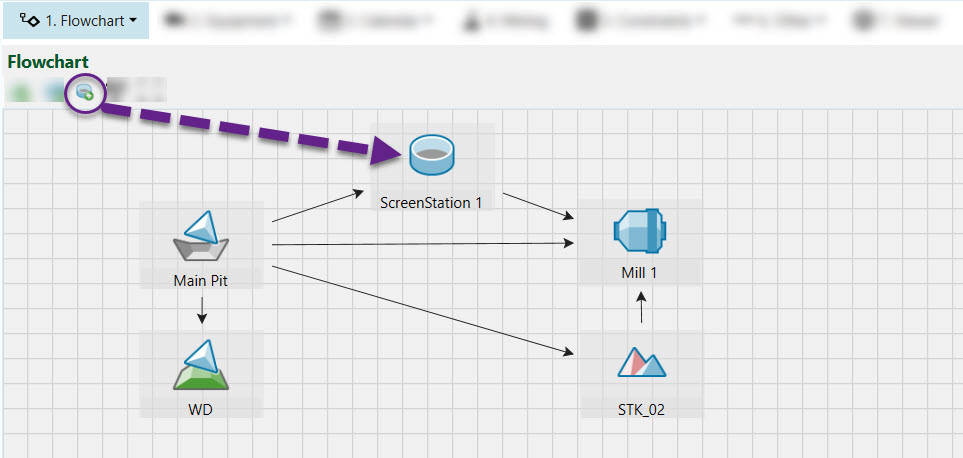

Screening stations are used to separate material into product and waste. To use this tab, screen stations need to be added to the flowchart using the Flowchart toolbar .

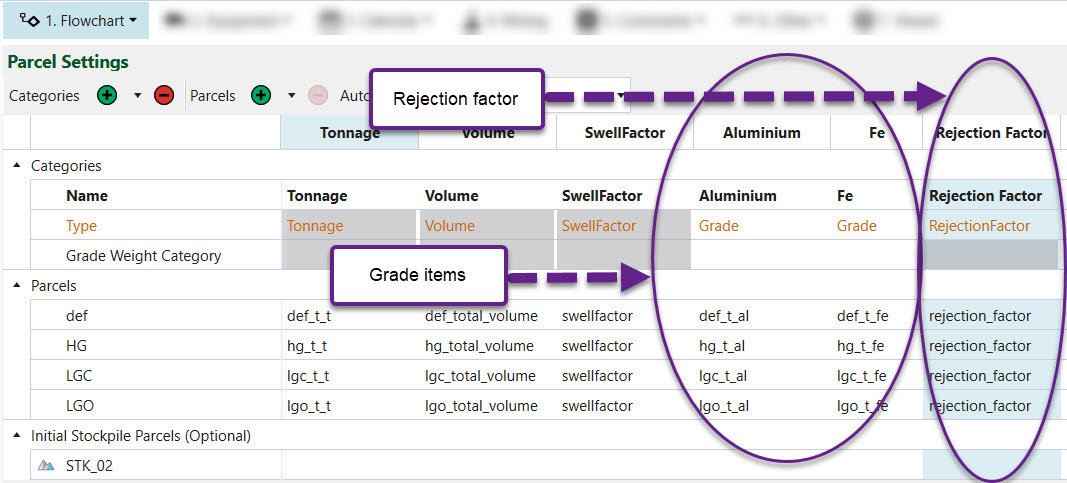

Grade categories also need to be defined in the Flowchart > Parcel Settings tab. A Rejection factor should also be added. It is a value between 0.0 and 1.0 and defines how much material isn't processed by the screening station.

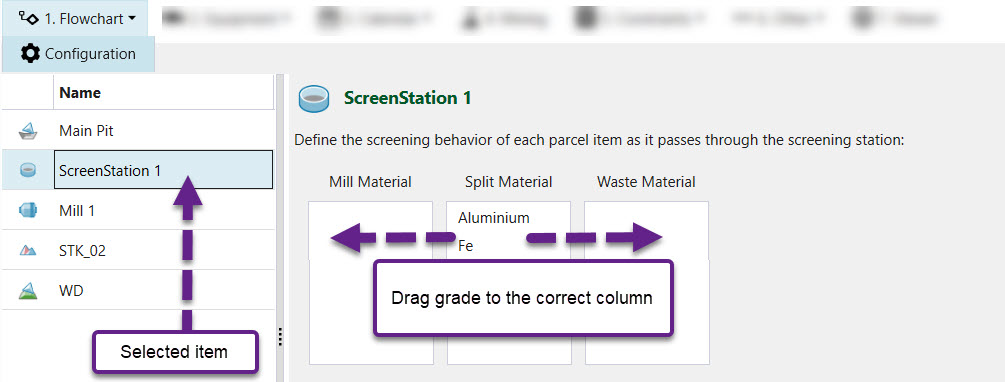

In the Flowchart > Configuration tab, the material processed by the screen station can categorised in the three different ways:

- Mill material — Material is sent directly to the mill.

- Waste material — Material is sent directly to the waste dump.

- Split material — Material split by a Rejection factor and then sent to the mill or waste dump.

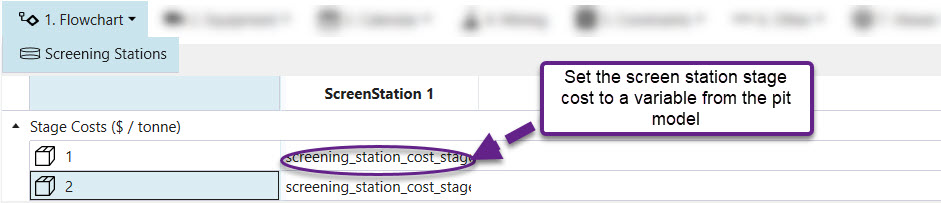

In the Flowchart > Screening stations tab, you define the value of sending material from a particular stage in the model to a screening station included in the setup. Attributes from the reserve model are used to set the cost. This step is optional.

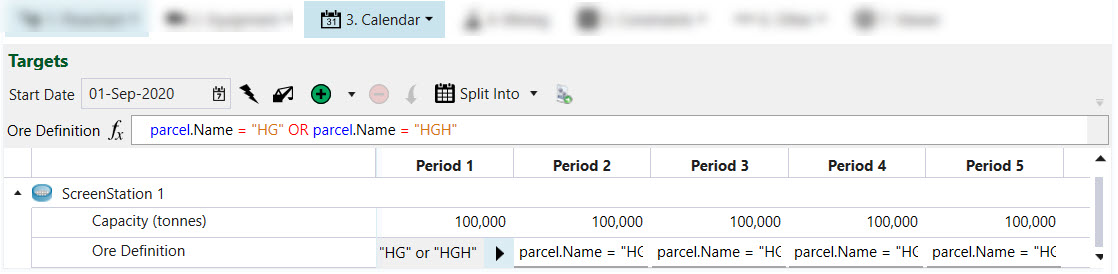

Once the screening station has been configured, you can define what kind of material can be processed by the screening station in the Calendar > Calendar tab under the Ore Definition field. The ore definition is parcel based.

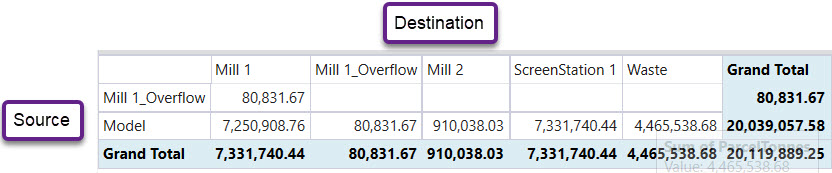

Once the setup has been run, and the resulting schedule has been downloaded, a pivot report (see Pivot Reporting) can be created showing the amount of material processed by the screening station.