Material Movement

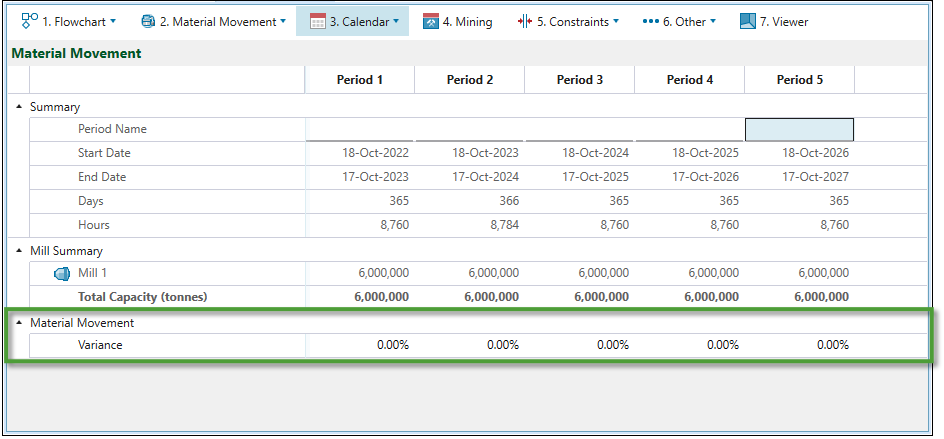

The ![]() Material Movement target is a variance which is set per period. It is used to control the allowable variance for each period of the schedule from the total material moved, total ore moved, and total equipment hours available in the calendar. A variance of 5% would allow any schedule between 95% and 105% on the calendar maximum to be regarded as not violating the given value. This is used to evaluate how well a given schedule utilised its mills and (or) diggers. Consequently, this value represents the degree of accuracy required when the software is aiming to meet the end of period targets set in the

Material Movement target is a variance which is set per period. It is used to control the allowable variance for each period of the schedule from the total material moved, total ore moved, and total equipment hours available in the calendar. A variance of 5% would allow any schedule between 95% and 105% on the calendar maximum to be regarded as not violating the given value. This is used to evaluate how well a given schedule utilised its mills and (or) diggers. Consequently, this value represents the degree of accuracy required when the software is aiming to meet the end of period targets set in the ![]() Calendar >

Calendar > ![]() Targets tab.

Targets tab.

Note: The target will not be affected by variance if a range is set. In that case, the target will be positioned in the middle of the range.

Fleet Code

Fleet Code

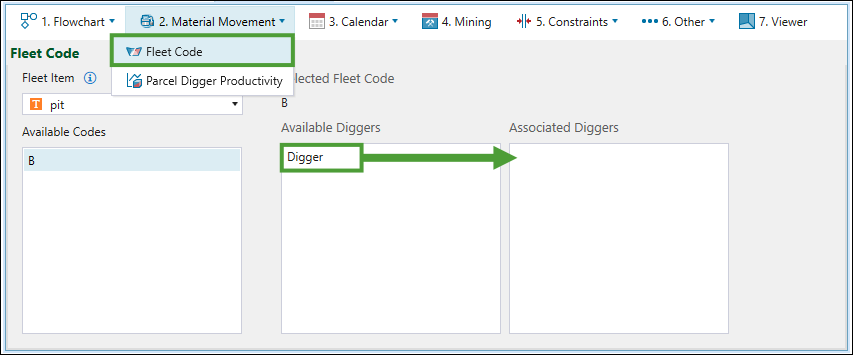

Use the  Fleet Code tab to assign diggers to regions of the model with specific attribute valu es. For example, diggers can be assigned to parts of the model based on lithology or stage.

Fleet Code tab to assign diggers to regions of the model with specific attribute valu es. For example, diggers can be assigned to parts of the model based on lithology or stage.

To do so, choose an item from the Fleet Item drop-down menu, which will define the codes to which your equipment is mapped. Next, drag the diggers listed in the Available Diggers field to the Associated Diggers field, which will allow mapping to the selected fleet code.

Parcel Digger Productivity

Parcel Digger Productivity

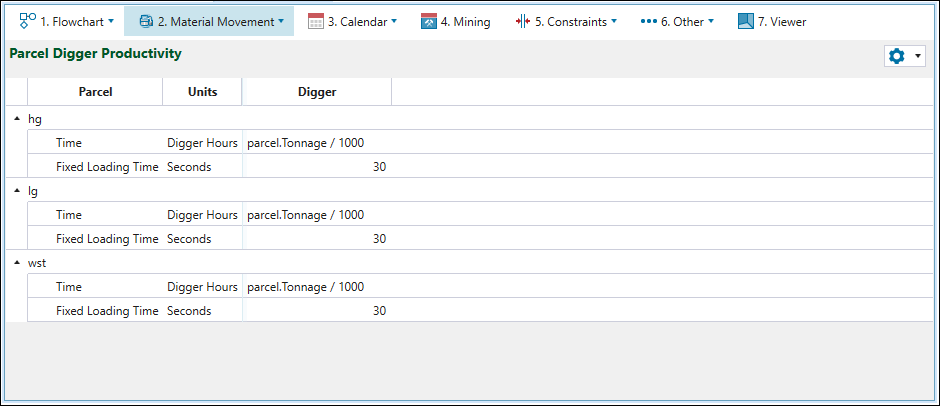

The  Parcel Digger Productivity tab is used to define the rate of material transfer for each digger per parcel. The duration is commonly a parcel-based equation written in a script field. The following is an example of a production duration in digger hours:

Parcel Digger Productivity tab is used to define the rate of material transfer for each digger per parcel. The duration is commonly a parcel-based equation written in a script field. The following is an example of a production duration in digger hours:

Production (digger hours) = parcel.Tonnage/1100, where the denominator is a fixed rate in tonnes per digger hour.

Example: For a solid with an ore parcel with 1500 tonnes and a waste parcel with 500 tonnes, the solid would take two hours to process.

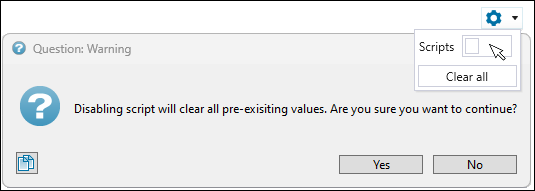

Tip! To disable the script, click ![]() Settings and then toggle the Scripts button in the drop-down menu to the off position. A warning pop-up window will appear so that your selection can be confirmed.

Settings and then toggle the Scripts button in the drop-down menu to the off position. A warning pop-up window will appear so that your selection can be confirmed.

Calendar

Calendar

The ![]() Calendar >

Calendar >  Material Movement objectives are used to control the waste variance tolerance for each period of the schedule. Evolution uses the waste tolerance to control how hard the scheduler must work during each period to achieve the movement target. A higher percentage number will generate a lower fitness, whereas a lower percentage variance will result in the scheduler refining the result based on a higher fitness value.

Material Movement objectives are used to control the waste variance tolerance for each period of the schedule. Evolution uses the waste tolerance to control how hard the scheduler must work during each period to achieve the movement target. A higher percentage number will generate a lower fitness, whereas a lower percentage variance will result in the scheduler refining the result based on a higher fitness value.