Calendar

The ![]() Calendar subtab allows you to specify the costs and processing capacity for each period of your setup.

Calendar subtab allows you to specify the costs and processing capacity for each period of your setup.

Calendar

Calendar

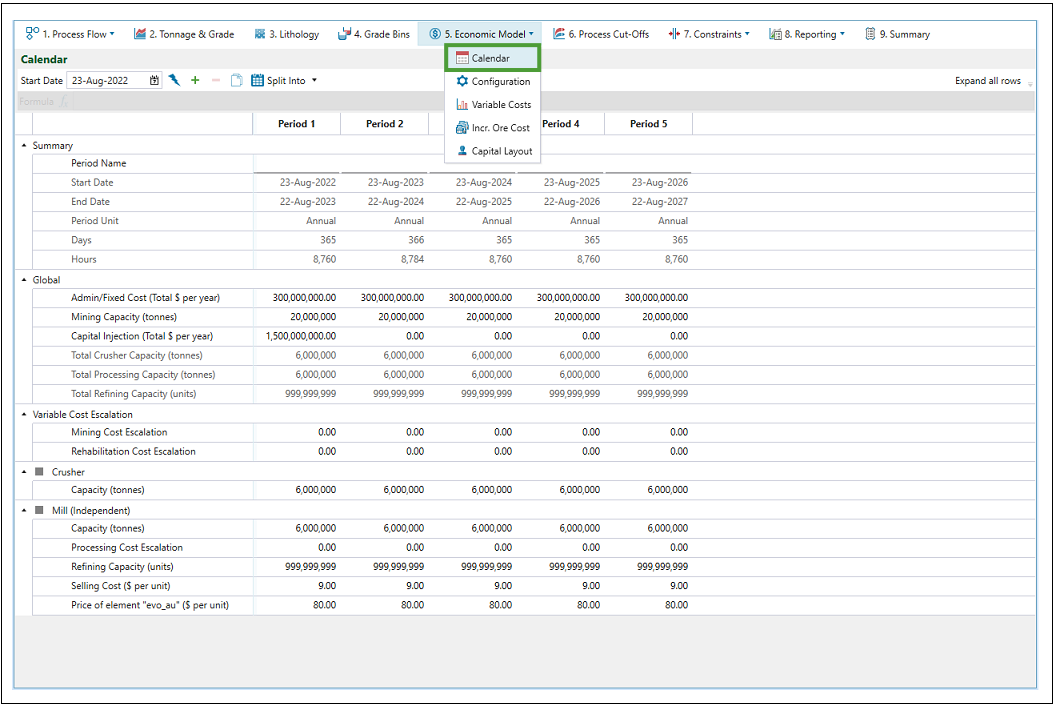

To enter the Calendar subtab, go to the Economic Model tab and select ![]() Calendar from the drop-down list.

Calendar from the drop-down list.

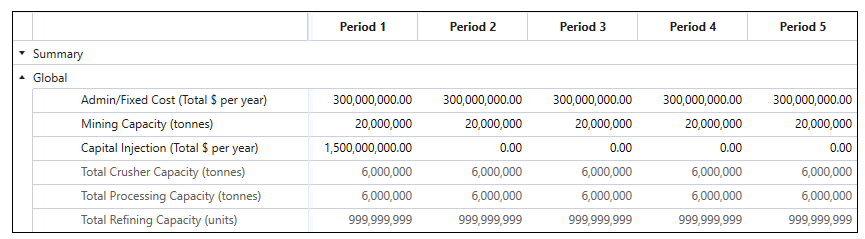

The Calendar subtab features the following controls:

|

Start Date

Sets the desired start date of the period. Start dates of other consecutive periods are determined based on this date. |

|

|

Generate Periods

|

|

|

Add an extra period to the calendar

Note: This button will be dimmed if no periods have been added to your setup. Use the |

|

|

Delete currently selected period

Note: You can select multiple periods by pressing and holding Shift and selecting the periods you wish to delete. |

|

|

Copy calendar to clipboard

Allows you to copy calendar data to the clipboard so that it can be later pasted into another document. |

|

Split into

Allows you to split the view of the selected period to display the data on a monthly, quarterly, or biannual basis. |

Parameters

The parameters that you can set in the ![]() Economic Model >

Economic Model > ![]() Calendar subtab are divided into the following groups:

Calendar subtab are divided into the following groups:

- Summary

- Global

- Variable Cost Escalation

- Crusher

- Process

- Beneficiation Group

- Crusher

- Grinding, Flotation, Bulk Ore Sorting, Coarse Particle Recovery

- B.O.S. Rejects, C.P.R. Rejects, Flotation Rejects

- B.O.S. Stockpile Reclaim, C.P.R. Stockpile Reclaim, Flotation Stockpile Reclaim

- B.O.S. Waste Capacity, C.P.R. Waste Capacity, Flotation Waste Capacity

- Reclaim Processing

- Pits

- Stockpiles

- Stockpiles

Summary

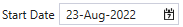

The Summary group provides information on the start and end dates of a period, as well as the length of each period. These intervals are calculated automatically when you create periods during calendar setup. You can define custom period names to easily identify these periods in other setup areas and reports. To do so, in the Period Name row, double-click on the cell that corresponds to the particular period and enter the desired name.

Global

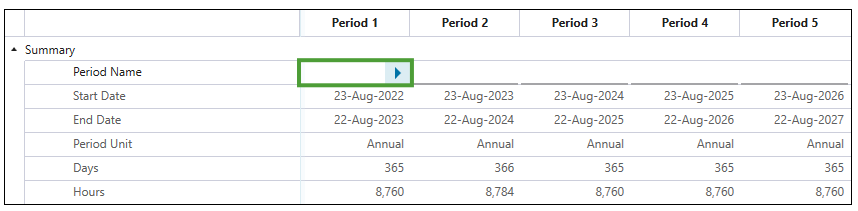

You can set the following parameters under the Global group:

-

Admin/Fixed Cost ($ per year): Costs that occur regardless of mine production. Administration and fixed costs should include not only various business costs, but also the mining expenses that are incurred regardless of production rate, i.e. maintenance, employment costs or loan repayments. Fixed costs are used in net present value (NPV) calculations, and hence influence the resultant schedule. Enter the costs that occur during mine operation.

-

Mining Capacity (tonnes per year): The maximum tonnage (waste and ore) that can be mined in all pits. To specify this mining target, use the Global Accumulation constraint. Although the upper limit that you set is a hard constraint (the limit must be obeyed by Evolution when a schedule is generated), Strategy can return schedules below this limit if they produce higher NPVs. See Global Accumulation for more information.

-

Capital Injection ($ per year): This parameter refers to the expenses that are incurred at fixed dates. Such costs are applied at the specified period, and are unrelated to the mine's status or operation. Enter any up-front or ongoing capital requirements.

Note: The capital spent on mine, mill or fleet expansions should be configured in

Economic Model >

Economic Model >  Capital Layout subtab, since such expenses occur at a known event, but unknown date. See Capital Layout for more information.

Capital Layout subtab, since such expenses occur at a known event, but unknown date. See Capital Layout for more information.Note: To configure the capital required due to dump expansions, go to the

Process Flow >

Process Flow >  Configuration subtab and specify the Incremental Capacity (t) and Incremental Cost ($) for each dump. See Configuration for more information.

Configuration subtab and specify the Incremental Capacity (t) and Incremental Cost ($) for each dump. See Configuration for more information.Note: The Capital Injection row can be replaced with multiple itemised capital expenditures through

Economic Model >

Economic Model >  Configuration page. See Configuration for more information.

Configuration page. See Configuration for more information. -

Total Crusher Capacity: This non-editable parameter shows the summed total of all crusher capacities in the setup.

-

Total Processing Capacity: This non-editable parameter shows the summed total of all process feed capacities in the setup.

-

Total Refining Capacity: This non-editable parameter shows the summed total of all process refining capacities in the setup. This is the maximum amount of product that can be produced.

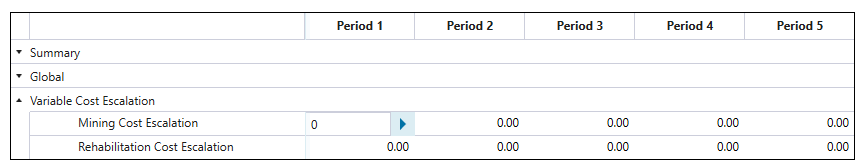

Variable Cost Escalation

Typically, mining and rehabilitation costs tend to vary based on the mining location in the pit, thus they are known as variable costs. However, these costs may increase over time due to inflation or other external factors. To account for these increases, the amount increasing the variable costs can be entered for each period under the Variable Cost Escalation category in the calendar. The increased costs that can be entered are as follows:

-

Mining Cost Escalation

An additional mining cost (in currency units) that can be specified individually for each period. This cost is applied to every tonne of material mined in that period. -

Rehabilitation Cost Escalation

An additional, associated with rehabilitation of waste material, cost (in currency units) that can be specified individually for each period. This cost is applied to every tonne of material mined in that period.

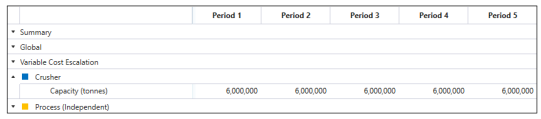

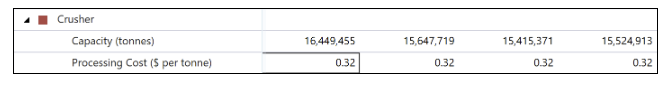

Crusher

Each crusher in the flowchart has its own group of parameters displayed in the calendar.

The Capacity (tonnes) parameter that corresponds to the Crusher category in the calendar specifies the maximum feed tonnes the crusher can accept. A returned schedule may use less than this capacity, but never more. Enter the crusher limit of the primary crusher.

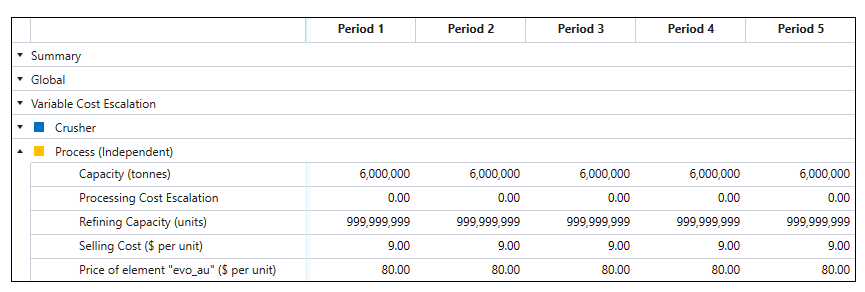

Process

Each process in the flowchart has its own group of parameters displayed in the calendar.

You can specify the following parameters for each process:

-

Capacity (tonnes)

The maximum feed tonnes the process can accept. A returned schedule may use less than this capacity, but never more. You can use a Process Accumulation constraint if there is a target capacity you would like to achieve. For more information, see Process Accumulation.

-

Processing Cost Escalation

An additional processing cost (in currency units) that can be specified individually for each period. This cost is applied to every feed tonne for that period.

Note: This is in addition to processing costs specified in the

Configuration subtab. For more information, see Configuration.

Configuration subtab. For more information, see Configuration. -

Refining Capacity (units)

The maximum amount of metal (or product) that can be produced by the process. Specify this amount in product units.

-

Selling Cost ($ per unit)

The costs incurred when one unit of product is sold.

-

Price of element ($ per unit)

The amount of revenue expected for each unit of product that is produced by the process.

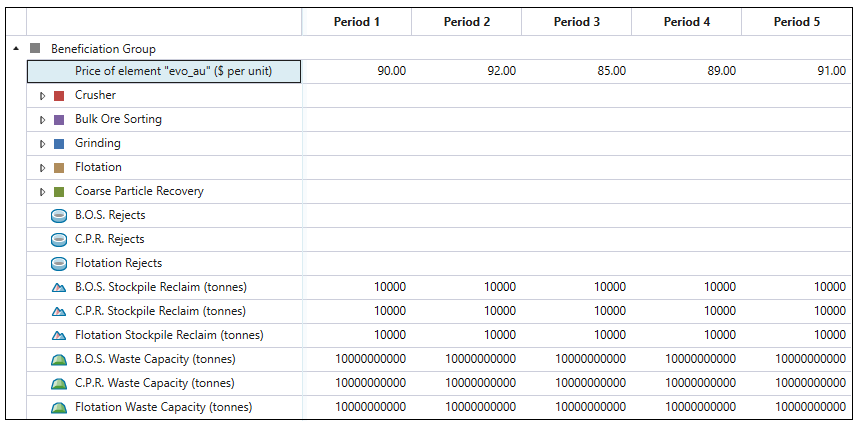

Beneficiation Group

Each beneficiation group in the flowchart has its own set of parameters displayed in the calendar.

Price of element ($ per unit), which you can set for the whole beneficiation group, is the parameter that specifies the amount of revenue expected for each unit of product produced by the process.

Crusher (subprocess)

You can specify the following parameters for the crusher within the beneficiation group:

-

Capacity (tonnes)

The maximum feed tonnes the crusher in the beneficiation group can accept. A returned schedule may use less than this capacity, but never more.

-

Processing Cost (for Crusher subprocess)

The processing cost (in currency units) per feed tonne for the crusher in the group.

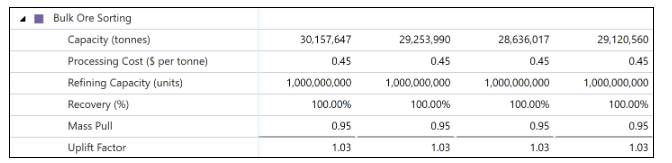

Grinding, Flotation, Bulk Ore Sorting and Coarse Particle Recovery

Each of these subprocesses share the same parameters:

-

Capacity (tonnes)

The maximum feed tonnes the subprocess in the group can accept. A returned schedule may use less than this capacity, but never more.

-

Processing Cost ($ per tonne)

The processing cost (in currency units) per feed tonne for the subprocess in the group.

-

Refining Capacity (units)

The maximum amount of metal (or product) that can be produced by the subprocess. Specified in product units.

-

Recovery (%)

The factor that is used to simulate the inefficiencies of the process. The recovery factor represents the amount of high-grade ore that is sent to the product stream, versus the grade that is specified by the Uplift Factor. A factor of 95% would result in the uplifted grade being reduced by 95%, with the rejects’ stream having its grade increased to represent high grade material incorrectly reporting to it.

-

Mass Pull

The factor that specifies how much of the feed should pass to the product output stream of the subprocess. The remaining amount is sent to the rejects’ output stream. A factor of 0.95 would result in 95% of the feed tonnes flowing to the product stream, and 5% to the rejects. This can be specified as either a fixed number, or a variable in the block model.

-

Uplift Factor

The factor by which the grade in the product stream is increased compared to the feed. This in turn results in the reduction of grade in the rejects’ stream. A factor of 1.05 would result in the product stream having a grade 5% higher than the feed. You can specify this as either a fixed number, or a variable in the block model.

B.O.S Rejects, C.P.R. Rejects, and Flotation Rejects

Reject material from the Bulk Ore Sorting (B.O.S.), Coarse Particle Recovery (C.P.R.), and Flotation subprocesses can be sent to either a stockpile or waste dump attached only to that subprocess. Stockpile material is then reclaimed and processed in the Reclaim Mill.

The Stockpile Proportion, which is a common parameter for the nodes that process rejects, is a factor that specifies how much of the associated reject stream should be stockpiled. The remaining amount is sent to the attached waste dump.

B.O.S Stockpile Reclaim, C.P.R. Stockpile Reclaim, and Flotation Stockpile Reclaim

The stockpiles associated with the Bulk Ore Sorting, Coarse Particle Recovery, and Flotation subprocesses must have their reclaim amount set by period. By the end of the schedule, all stockpiles must be reclaimed, hence the final period in the calendar must have a non-zero reclaim amount that is high enough for the schedule to finish within the maximum number of periods specified for that schedule. There are usually 100 periods in the schedule, but you can increase this number in the ![]() Advanced Options tab. See Advanced for more information.

Advanced Options tab. See Advanced for more information.

B.O.S Waste Capacity, C.P.R. Waste Capacity, and Flotation Waste Capacity

The waste dumps associated with the Bulk Ore Sorting, Coarse Particle Recovery, and Flotation subprocesses can each have an upper limit. The capacities represent the total capacity of the dump in that period, and not the increase in capacity from period to period.

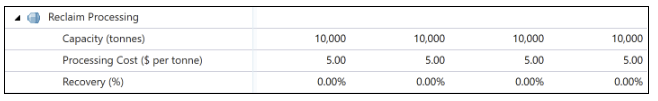

Reclaim Processing

Reclaim Processing, which is a common operation for the nodes related to the reclaims within beneficiation group, comprises the following parameters:

-

Capacity (tonnes)

The maximum feed tonnes a subprocess in the group can accept. A returned schedule may use less than this capacity, but never more.

-

Processing Cost ($ per tonne)

The processing cost (in currency units) per feed tonne for the subprocess in the group.

-

Recovery (%)

The percentage of product or metal in the stockpile material that will be extracted by the mill. This factor allows for the modelling of inefficiencies in the mill that prevent the recovery of all metal (products) in the mill’s feed.

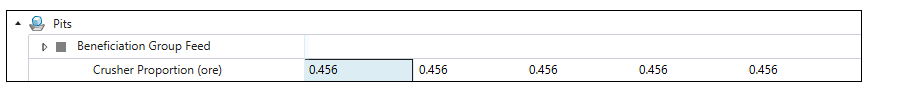

Pits

Note: This section appears in the calendar only when one or more beneficiation groups are added to the flowchart.

For each lithology, specify the proportion of group feed that is sent to the crusher process. The remaining amount will be sent for bulk ore sorting. You can specify this value as either a number, or a block model variable.

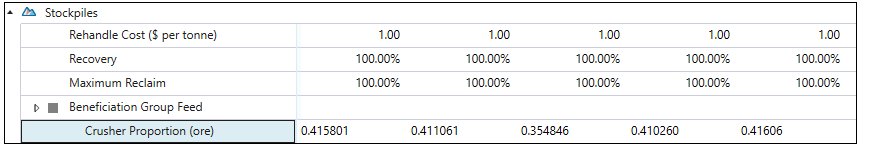

Stockpiles in beneficiation group

If your beneficiation group is fed by a stockpile, then a Beneficiation Group Feed section will be added under the Stockpiles category in the calendar.

For each lithology, specify the proportion of group feed that is sent to the crusher process. The remaining amount will be sent for bulk ore sorting. You can specify this value as either a number, or a block model variable.

Stockpiles

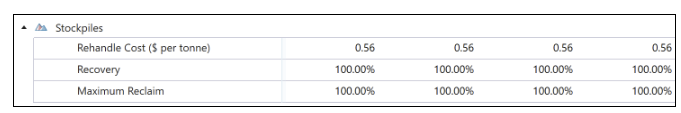

The following parameters are displayed for each stockpile that has been added to the flowchart:

-

Rehandle Cost ($ per tonne)

The cost of reclaiming one tonne of material from the stockpile to the mill.

-

Recovery

The percentage of product or metal in the stockpile material that will be extracted by the mill. This factor allows for the reduction in grade or loss of material during the stockpile process.

-

Maximum Reclaim

The maximum amount of the stockpile that can be reclaimed in the period. A value of 80% means that 80% of the material accumulated on the stockpile at the start of the period can be reclaimed.