Tonnage & Grade

Configuration

The ![]() Tonnage & Grade tab is used to specify the total capacity and ore capacity variables of the setup.

Tonnage & Grade tab is used to specify the total capacity and ore capacity variables of the setup.

Note: In Strategy, the terms element, metal, and product are used to refer to the saleable product of the operation. These terms are used interchangeably. For example, an operation may produce and sell the metal gold, while another operation may produce a copper concentrate as a product that is sold to a third-party refining operation.

The total capacity defines the total tonnes (ore + waste) contained in each block of your block model, whereas the ore capacity determines the tonnes of the ore parcel contained in each block of this model.

Note: Ore capacity must be equal or less than the total tonnage.

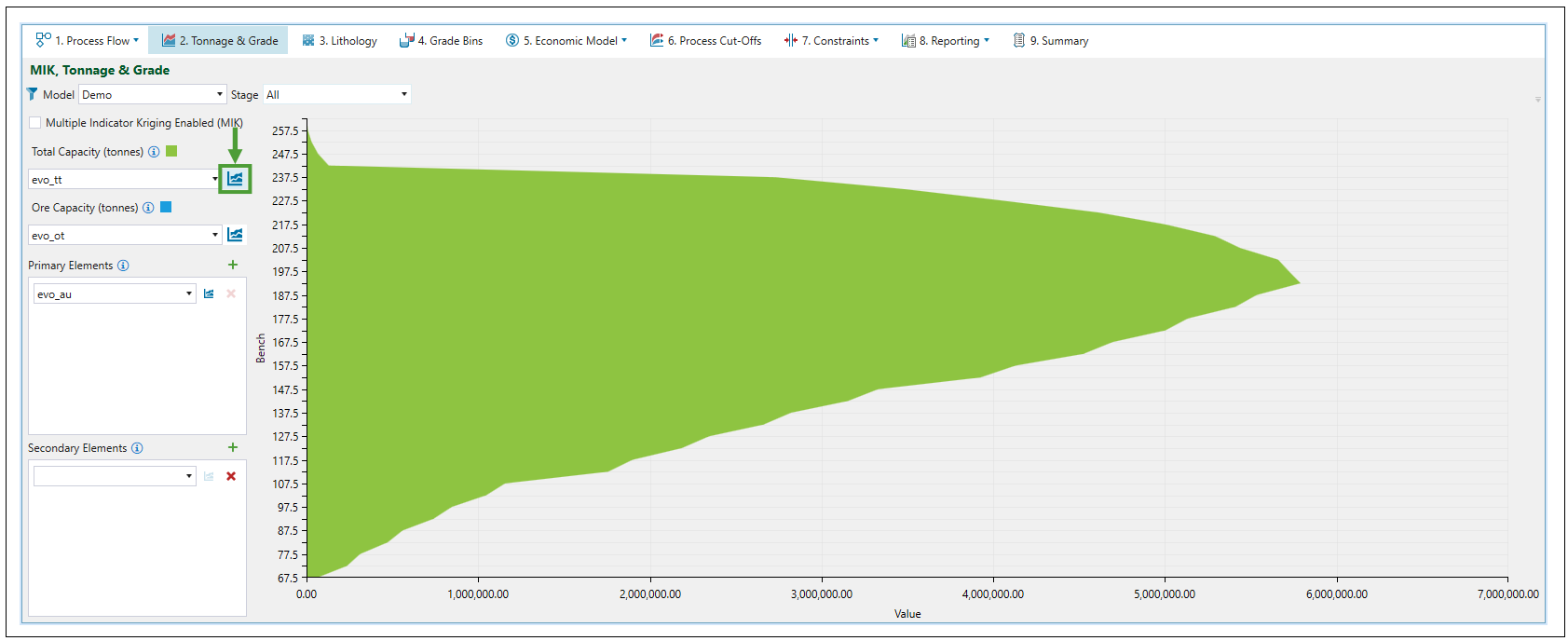

Once you apply these variables, you can visualise them in a graph to check the correlation between the calculated value and benches of your model. To display the graph for the required variable, click the ![]() button next to the corresponding drop-down menu.

button next to the corresponding drop-down menu.

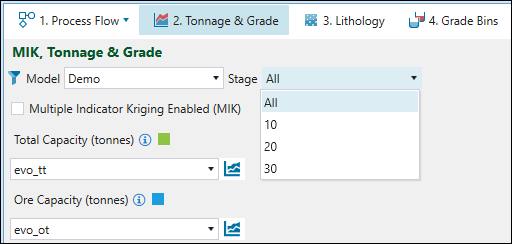

Note: You can select the model and the stage of your setup for which you want the graph to be generated. To do so, select the appropriate item from the Model and Stage drop-down menus.

In this tab, you can also add primary and secondary elements to your setup.

Primary elements are the pit model variables that represent the grades of elements for which an optimal cut-off grade policy should be produced. The cut-off grade policy is the element’s cut-off grade for each process in each period. These grades are used to calculate the amount of metal or product that will be produced by mill processes, which in turn earns revenue for the operation. For more information, see Process Cut-Offs.

On the other hand, secondary elements are the pit model variables that represent the grades of elements that contribute to the revenue of the operation, but for which no cut-off grade policy should be determined.

-

Click

and select the variable from the drop-down menu to add another primary element or a secondary element to your setup.

and select the variable from the drop-down menu to add another primary element or a secondary element to your setup. -

Click

to delete the element.

to delete the element. -

Click

next to the element's drop-down menu to display the graph showing the correlation between the calculated value and each bench for that element.

next to the element's drop-down menu to display the graph showing the correlation between the calculated value and each bench for that element.

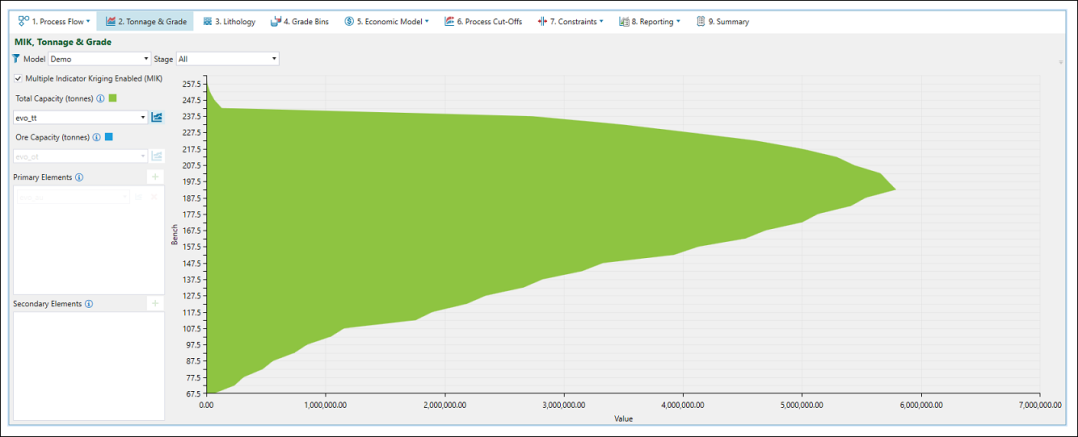

Note: Only the variable in the Total Capacity (tonnes) field can be specified when the Multiple Indicator Kriging Enabled (MIK) checkbox is selected. Other fields for setting the setup variables will be greyed out.

Calculations for produced metal and revenue

Note: In the user interface and help, the term metal is often used to refer to the product produced by the mill. This might be a refined metal, but could also be a concentrate or other type of product.

The main calculation formulas implemented in Evolution are as follows:

-

Calculating the total tonnage (expressed in tonnes)

,

where

indicates the total tonnes,

is the ore tonnes, and

is the waste tonnes.

-

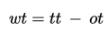

Calculating the waste tonnes (inferred)

,

,where

is the waste tonnes,

is the waste tonnes,  indicates the total tonnes, and

indicates the total tonnes, and  is the ore tonnes.

is the ore tonnes. -

Calculating the in situ metal (in units)

,

where

is the ore tonnes.

Example: If there are 25,000 ore tonnes of gold with an average grade of 5 grams / tonne, then

,

whereindicates gold,

indicates the grams, and

indicates the tonnes in the equation.

-

Calculating the amount of produced material (in units) with the consideration of the process recovery percentage

,

where

is the ore tonnes.

Example: If there are 25,000 ore tonnes of gold with an average grade of 5 grams / tonne, and the process recovery rate is 89%, then

,

whereindicates gold,

indicates the grams, and

indicates the tonnes in the equation.

-

Calculating the revenue

,

where

is the ore tonnes.

Example: If there were 25,000 ore tonnes of gold with an average grade of 5 grams / tonne, the process recovery rate was 89%, and the gold was sold for US $ 60 / gram, then

,

whereindicates the tonnes and

indicates the grams in the equation.

Tip! You can set the currency in

Settings (Home ribbon > Project group >

Settings (Home ribbon > Project group >  Settings).

Settings).

Single and multi-element setups

Single element setups

Setups with only one primary element selected are considered single element setups. Equivalent grades (for deposits with more than one element) can also be selected as a primary element.

Setups with a single element will produce schedules with net present value (NPV) optimal cut-off grades for each stockpile and process.

Multi-element setups

Strategy operates in multi-element mode when two or more primary elements are selected. Multi-element setups are useful when modelling multiple mill processes that can only accept some elements, but not all.

A mill might have a process that can produce both copper and gold, and another process that produces only gold. Two primary elements could be selected in this case:

-

An equivalent grade that combines both copper and gold grades. This can serve as a cut-off for the first process.

-

The second primary element is the gold grade that will be used for the cut-off of the second process.