Mining

Source file: origin-block-setups-mining.htm

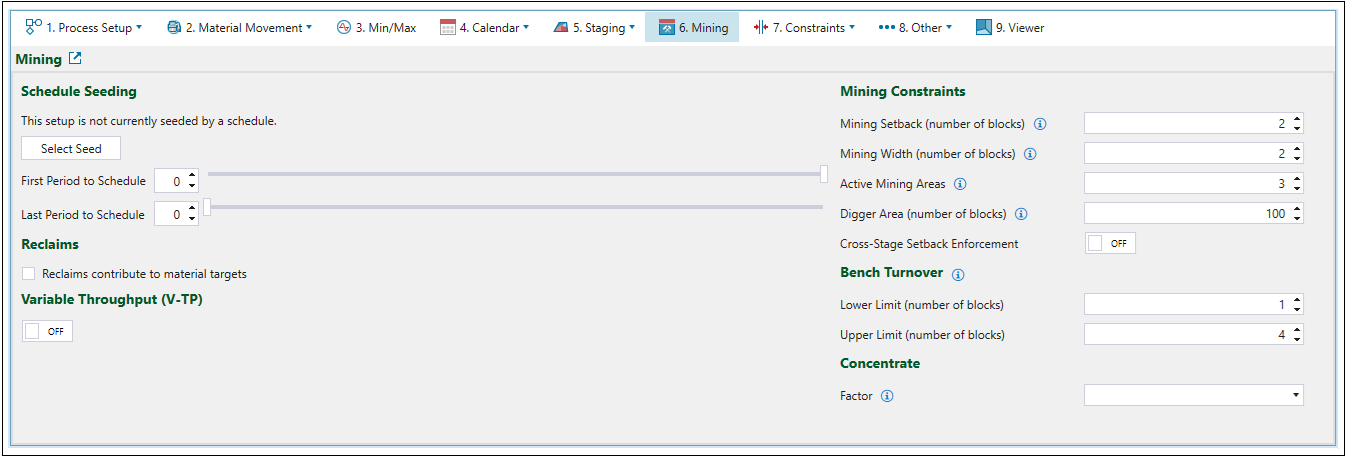

The ![]() Mining tab allows you to apply settings in the six separate sections.

Mining tab allows you to apply settings in the six separate sections.

Schedule Seeding

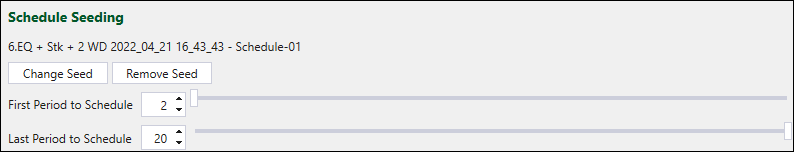

Use Schedule Seeding to replicate all or a part of a prior schedule in a new schedule. This is useful if you want to exactly keep earlier periods from a previous result, but make changes to and reschedule later periods. Because Evolution’s scheduling algorithms will often produce slightly different results each time you run a setup, use this functionality to lock in periods that you do not want to change.

To use an existing schedule as a seed, select it via the Select Seed button. The results from the selected schedule will be used up until the First Period to Schedule, after which new results will be generated. You can change or remove the seed schedule using the Change Seed or Remove Seed buttons.

Use the Last Period to Schedule field to turn off optimisation for later periods in order to speed up processing time. These periods will still be scheduled and will be numerically correct, but will often fail to meet targets or constraints since no optimisation was applied to them.

You can use Schedule Seeding to speed up iteration time when working on a complex scenario. For example, you can begin by setting the Last Period to Schedule to 5, and having no seed selected. When you obtain a result in which the first five years are suitable, select that result as a seed, set the First Period to Schedule as 6, and set the Last Period to Schedule as 10. Continue in this manner until you have scheduled your mine to completion.

Reclaims

Select the Reclaims contribute to material targets checkbox to include the reclaimed mass when applying the material targets.

The operation will be different based on the checkbox selection status:

-

Selected: Mining will stop when the material coming from the pit and from the reclaims reaches the target.

-

Not selected: Mining will stop when the amount of material that has come from the pit reaches the target.

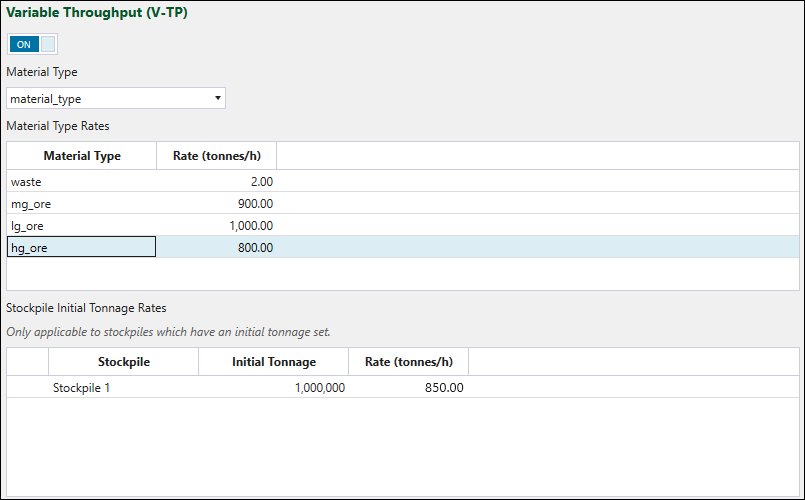

Variable Throughput (V-TP)

Use the Variable Throughput to base the mill capacity on the total crushing hours available in a period instead of on the ore tonnage. To set up the Variable Throughput, click the toggle button to enable this function. Next, select the required attribute from the Material Type drop-down and specify the rate (tonnes per hour) for each material type. The content of the Stockpile Initial Tonnage Rates table will reflect the stockpile initial tonnage settings that you have applied in the ![]() Configuration subtab (see Configuration for more information).

Configuration subtab (see Configuration for more information).

Important: While you must specify the rate for waste as a value above 1, Evolution will not take this value into account, as waste is not processed by the mill.

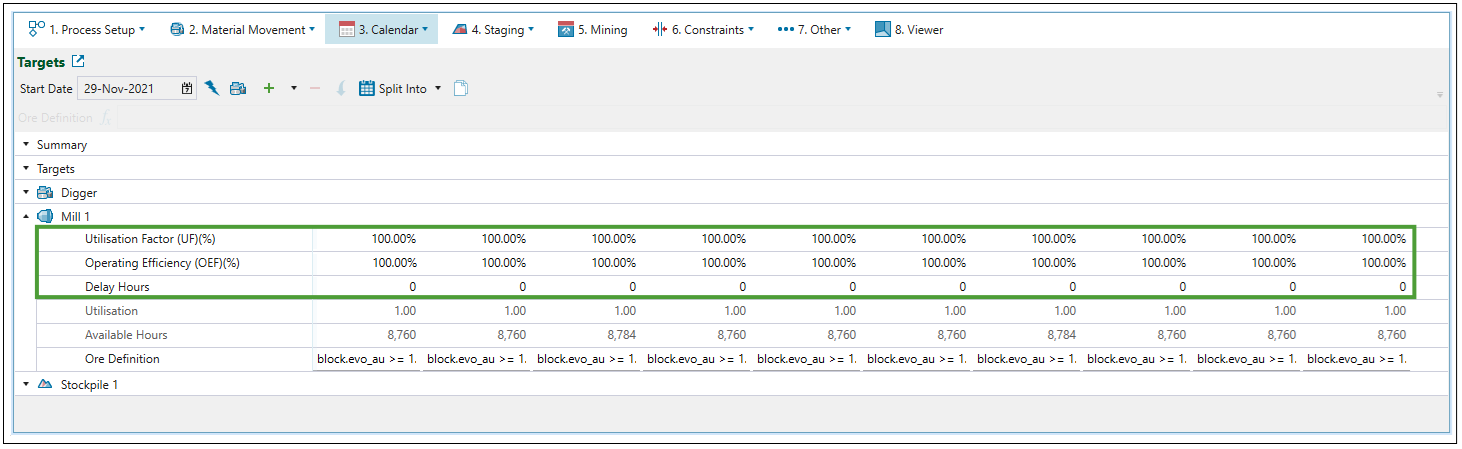

If you enable Variable Throughput, you will have to enter the Utilisation Factor, Operating Efficiency, and Delay Hours for the mill in the ![]() Calendar >

Calendar > ![]() Targets subtab.

Targets subtab.

Mining Constraints

You can set up the following mining constraints:

Note: These constraints are hard constraints. See Constraints for more information on the constraints that you can add to your Origin Blocks setup.

Mining Setback

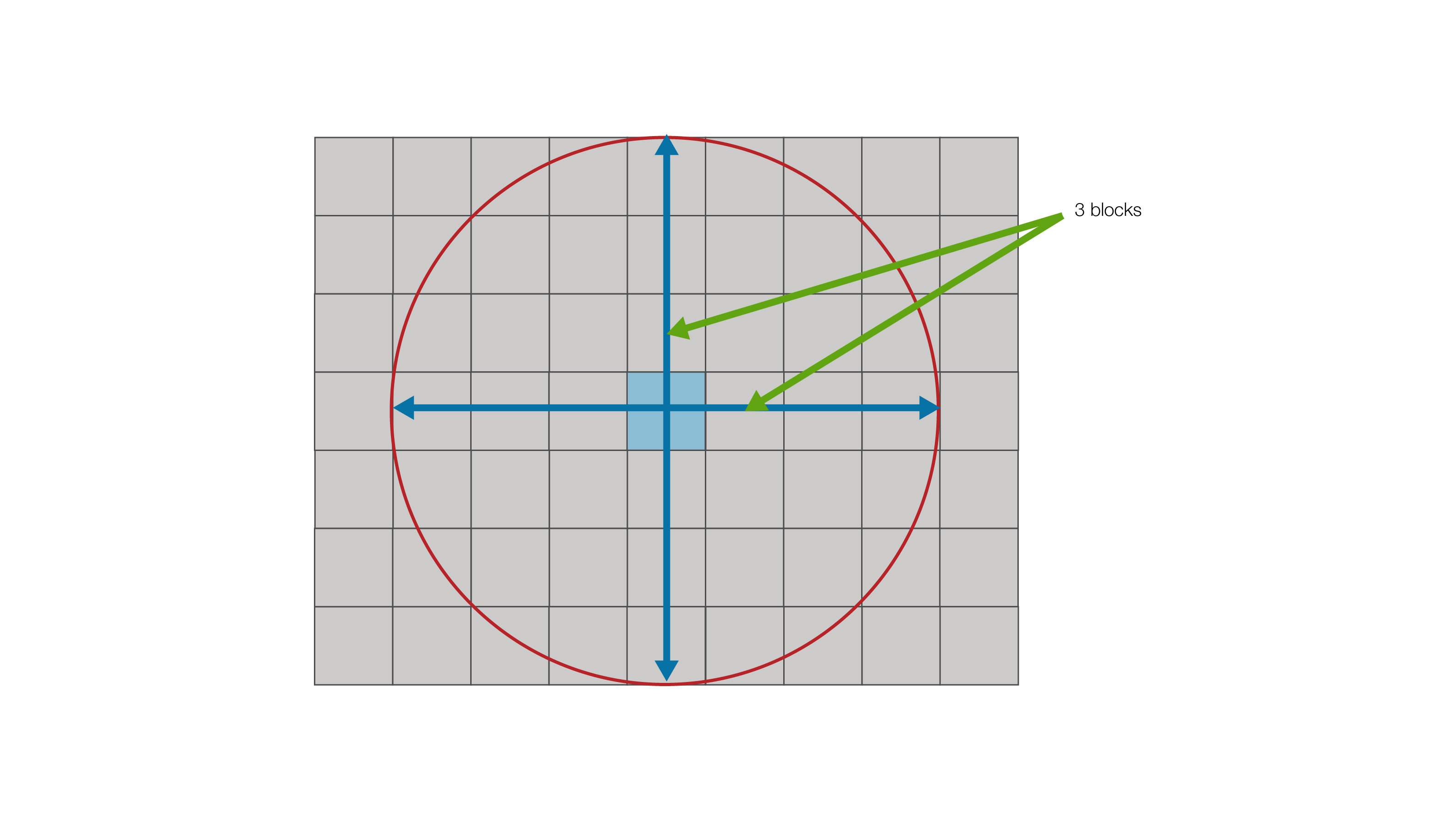

Mining Setback is the minimum number of blocks back from any block that you want to mine.

If you set Mining Setback to

3, the face of the bench above must be three blocks back from any block you want to mine. Partial mining cannot occur, as it has been specified that the active face of at least three blocks needs to be exposed once mining in that bench takes place.Note: The term face refers to the vertical wall of the bench, and the term active faces means the number of faces that are being worked on in the pit at a given time.

Mining Width

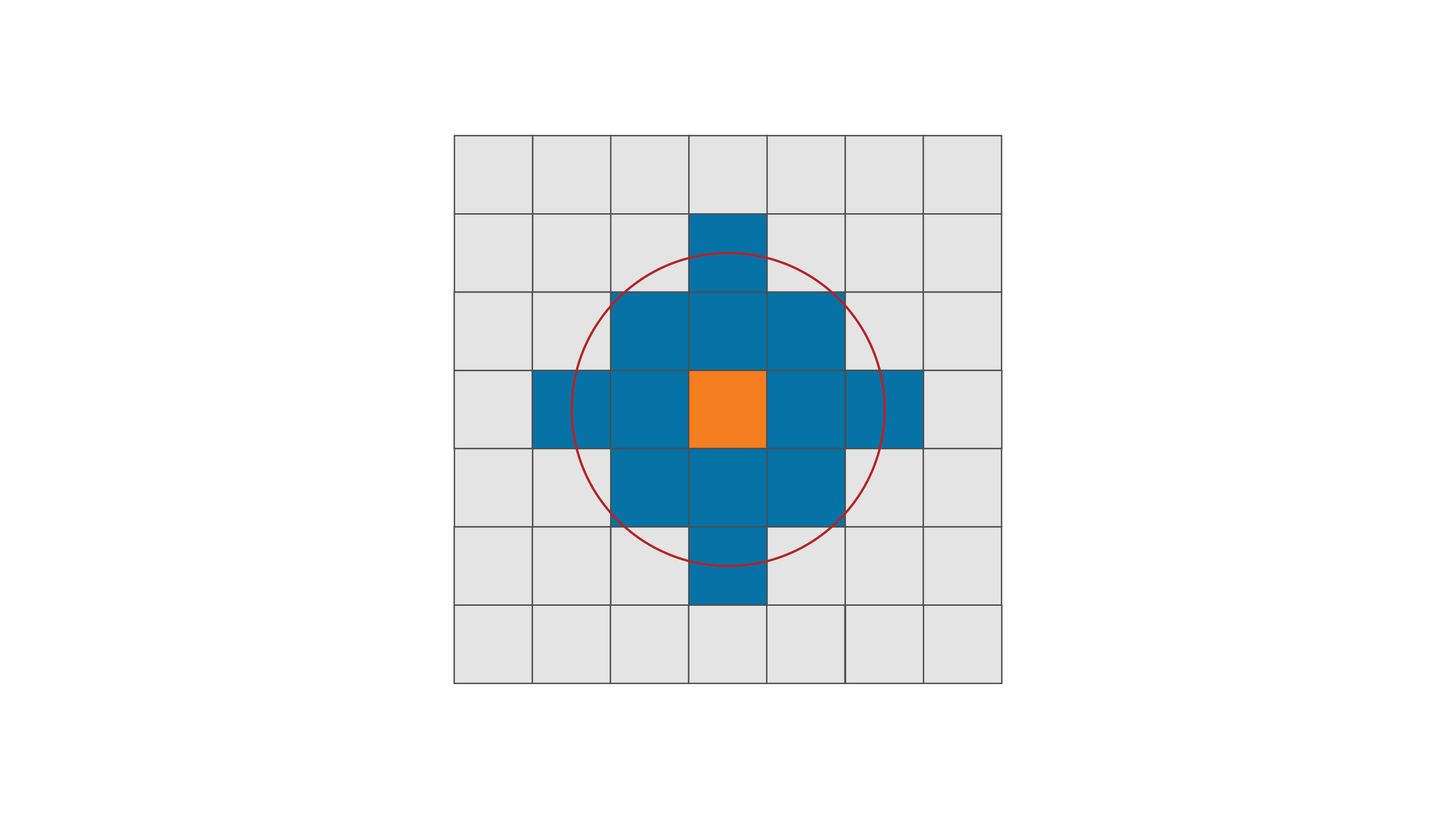

Use Mining Width to set the minimum space (specified by the number of blocks) required to access a new bench. The mining width, which is applied as a radius, is the product of the size of the block and the number of blocks, as shown on the image below.

Active Mining Areas

In Origin Blocks, a digger is moved to a location, and then allowed to mine within a given radius. The Active Mining Areas constraint sets the number of areas where the blocks are being mined at a given time.

Digger Area

The Digger Area constraint sets the number of blocks to be mined from an active area before a digger can be moved. This setting ensures the mining sequence can be practically achieved without requiring the mining fleet to be constantly relocated.

Cross-Stage Setback Enforcement

When you enable Cross-Stage Setback Enforcement, Evolution will check if there are any setback violations for blocks from all stages (instead of checking only the current blocks' stage).

Bench Turnover

The Bench Turnover inputs control how each bench within a stage is developing vertically. The lower and upper limit values are combined as a ratio (Lower Limit / Upper Limit) and are used as a probability that the optimiser will explore dropping down to a lower bench versus mining on the same bench. A lower ratio will result in a higher probability of choosing to drop down to the next bench.

Note: The default Lower Limit and Upper Limit setting ratio is 1 to 4.

Concentrate

Use the Concentrate factor if you wish to specify your process or mill capacities based on an attribute other than ore tonnes (for example, concentrate tonnes). The chosen concentrate factor (a variable in your pit block model) will be used to convert ore tonnes to an amount of concentrate using the following formula:

Evolution will compare process capacities to this concentrate amount rather than ore tonnes. However, ore haulage will be still based on ore tonnes.