Engine Parameters

Source file: origin-reserve-setups-engine-parameters.htm

The ![]() Engine Parameters tab allows you to adjust the parameters of the optimization engine. Evolution will take these parameters into account when it generates preliminary schedules. Next, by comparing the outcomes of the resulting preliminary schedules, Evolution will derive the final schedule that best meets the targets you have set.

Engine Parameters tab allows you to adjust the parameters of the optimization engine. Evolution will take these parameters into account when it generates preliminary schedules. Next, by comparing the outcomes of the resulting preliminary schedules, Evolution will derive the final schedule that best meets the targets you have set.

Population Size

The Population Size parameter sets the number of preliminary schedules that Evolution will create in each generation before deriving the final, optimal schedule. The greater the population size, the longer it will take to generate the final schedule. You can adjust the number of preliminary schedules to create by entering the required value in the Population Size field or by using the slider.

Note: The maximum Population Size value that you can set follows your project settings for Origin setups. See Origin for more information.

Violation Factor parameters

The performance of the main objective in your setup is determined by an aggregate of several setup violation values. A violation value represents the degree to which a particular final schedule result violates a corresponding setup target. You can apply a scaling factor to each violation value to weight its contribution to the performance of the main objective.

You can set these factors to values between 0 and 1 by entering the required values in the corresponding fields or by using the sliders. Evolution then multiplies each factor by the corresponding violation value to create scaled violation values. The default value for each factor is 1. You can configure the following violation factors:

| Haulage Hours Violation Factor |

Represents the degree to which the final schedule violates the haulage hours target. Note: This parameter is only available in Origin Solids Equipment setups. Evolution calculates this violation using the following formula:

where Example

If a setup has a target of 10 trucks, and the schedule uses 6 trucks, the violation value before scaling would be 0.4 (40%). |

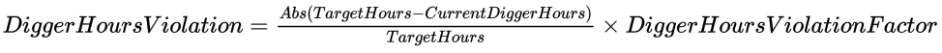

| Digger Hours Violation Factor |

Represents the degree to which the final schedule violates the digger hours target. Evolution calculates this violation using the following formula:

where Example

If a setup has a digger hours target of 500, and the schedule achieves 700 digger hours, the violation value before scaling would be 0.4 (40%). |

| Ore Target Violation Factor |

Represents the degree to which the final schedule violates the ore target. Evolution calculates this violation using the following formula:

where Example

If a setup has a mill target of 200, and the schedule achieves a process accumulation of 120, the violation value before scaling would be 0.4 (40%). |

| Ore Waste Violation Factor |

Represents the degree to which the final schedule violates the material movement target in terms of ore waste. Evolution calculates this violation using the following formula:

Example

If a setup has a material movement target of 1000, and a period in the schedule contains 450 waste ore tonnes, the violation value before scaling would be 0.45 (45%). |

| Ore Rehandle Violation Factor |

Represents the degree to which the final schedule violates the ore target in a given period, in terms of rehandled ore. Evolution calculates this violation using the following formula:

Example

If a setup has an ore period target of 1000 tonnes, and the schedule contains 300 tonnes of overflow material, the violation value before scaling would be 0.3 (30%). |

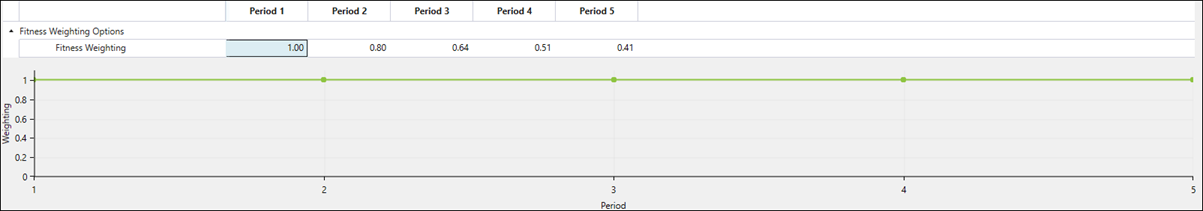

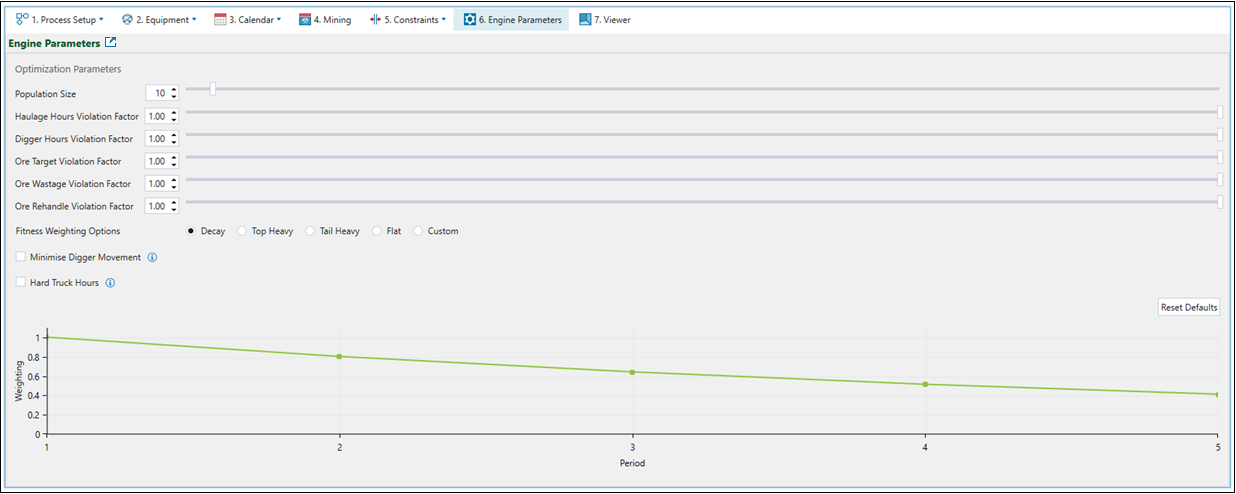

Fitness Weighting Options

Use the Fitness Weighting Options to alter the schedule results by giving additional weight to certain periods.

Note: If the schedule needs to be extended beyond the time frame defined in your setup so that the targets can be met, Evolution will reuse the value from the last period for later periods.

Select the radio button corresponding to the one of the following options:

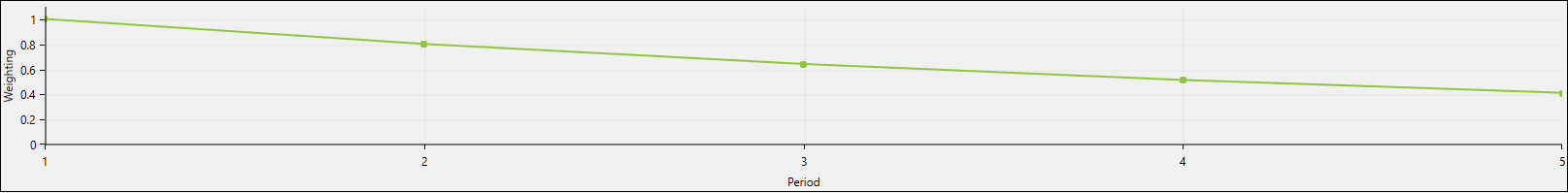

| Decay |

Gives more weight to the initial periods than to the later periods.

|

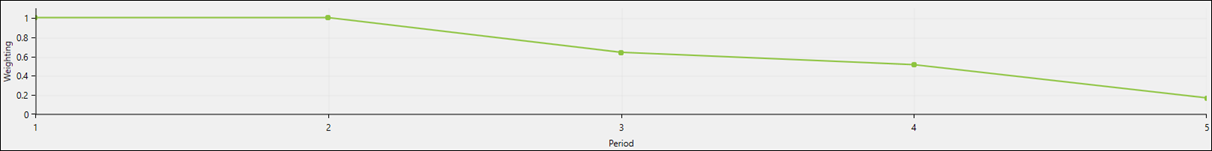

| Top Heavy |

Favours only the initial periods and minimises the impact of later periods on the schedule result.

|

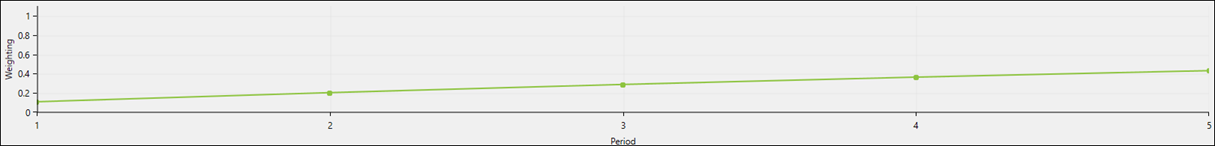

| Tail Heavy |

Favours only the initial periods and minimises the impact of later periods on the schedule result.

|

| Flat |

Assigns the weight of 1 to all periods.

|

| Custom |

Allows you to define the weighting for each period.

|

Minimise Digger Movement

If you enable the Minimise Digger Movement option, Evolution will take a digger’s location into account when moving it to a new mining location. This will streamline the movement of diggers across the mine, and minimise their sporadic movement from one solid to another distant solid.

If all available digger hours in a given period are exhausted without reaching the end of period target, Evolution will return a setup error and will not generate additional diggers to meet the end of period target. If further digger operation is not possible due to exhausting all available truck hours before meeting the end of period target, Evolution will also return a setup error.

To enable the Minimise Digger Movement tool, select the checkbox corresponding to it. Once the tool is enabled, Evolution will display the following setting options for you to customise the sequencing behaviour:

-

Enforce Neighbourhood Completion: Select this checkbox to ensure the digger finishes operation in the defined neighbourhood. To define the neighbourhood, enter the values in the following fields:

-

Neighbourhood Size: The number of solids on the same or higher bench.

-

Drop Down Neighbourhood Size: The number of solids on a bench lower than the current neighbourhood.

-

Drop Down Chance: The likelihood that the digger will move downwards instead of across when selecting its next task. It is a value between 0 and 1, with 1 being a 100% chance of dropping down.

-

Hard Truck Hours

Select Hard Truck Hours to set the diggers to be used only if they have at least one associated truck with remaining hours. Consequently, if a digger with multiple associated trucks is chosen to mine a solid, Evolution will engage only the trucks that have available hours left to process the material. However, if there are no better options, a truck with available hours will be chosen even if it cannot transport all of the solid's material without exceeding its available hours.

If a truck has used 999 out of 1000 hours that have been assigned to it, it can still be used to haul material from a solid. If the solid requires 10 haulage hours, the truck will end up operating for 1009 hours instead of the initially set 1000 hours, and will not be used again after finishing operation on the given solid.

Note: The smaller the solid, the smaller violation of truck hours will be.

,

,