Material Flow

Source file: epoch-setups-flowchart-flowchart.htm

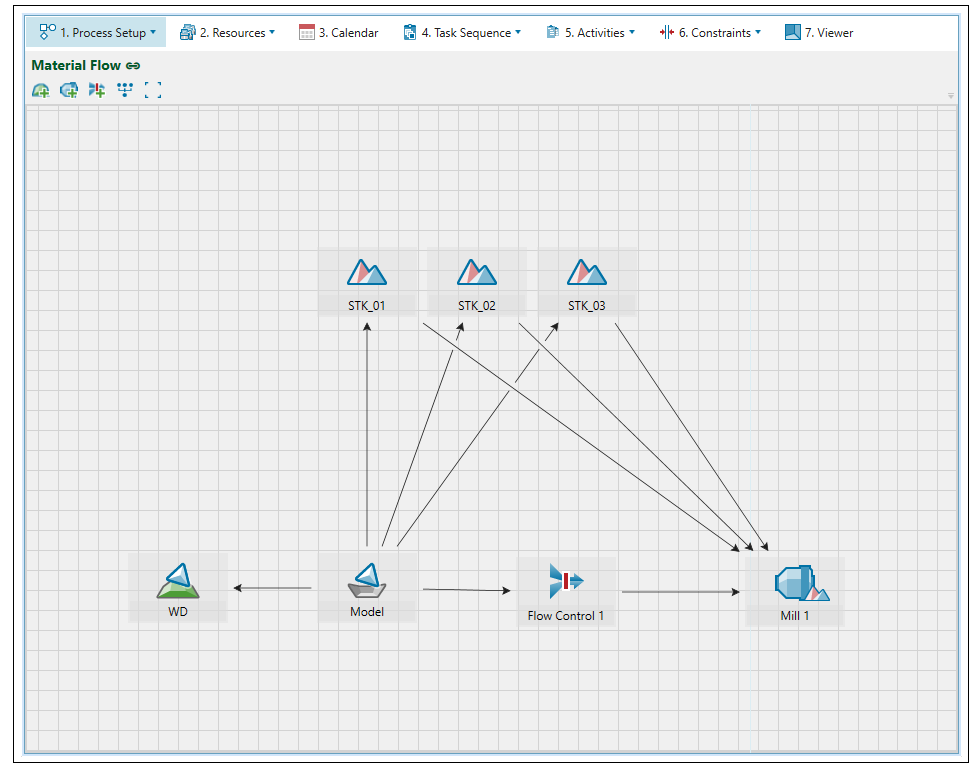

The ![]() Material Flow tab is used to define the flow of material within a setup by adding process components and linking them together.

Material Flow tab is used to define the flow of material within a setup by adding process components and linking them together.

Below is a list of process components that can be added to an Epoch setup. Components are categorised as either virtual or imported.

| Icon | Label | Type | Description |

|

|

Waste dump | Virtual | A waste dump is used to store waste material sent from a pit. |

|

|

Mill | Virtual | A mill processes material sent from a pit. Generally, an overflow stockpile is situated adjacent to it for the easy storage of low grade material. |

|

|

Flow control node | Virtual | A flow control node mimics the behaviour of a shaft in a mine. It is used to limit the amount of material transferred between a pit and a destination. |

|

|

Reserve pit | Imported | A reserve pit represents a mining site. It is made up of irregularly shaped units described as solids. |

|

|

Reserve waste utility | Imported | A reserve waste utility is used to store waste material sent from a pit. It contains geometrical information that helps you to pinpoint where material is sent. |

|

|

Reserve stockpile | Imported | A reserve stockpile is a temporary storage site for low grade material. Later on in the schedule, material is sent from a stockpile to the mill to achieve end-of-period targets. |

Once components have been added, the flow of material can be defined by linking them together. To create a link between component A and B, complete the following steps:

-

Click on component A. A white circle with a black outline will appear in the middle of the component.

-

Click on the circle in the middle of component A an drag the arrow all the way to the black circle on component B and wait until the circle has a grey outline.

-

Release the mouse. The link should be created.