Targets

Source file: origin-block-setups-calendar-targets.htm

Use the ![]() Targets subtab to define parameters per period in the production cycle. You can specify targets and target values in each period for each processing node, stockpile, and equipment in your setup.

Targets subtab to define parameters per period in the production cycle. You can specify targets and target values in each period for each processing node, stockpile, and equipment in your setup.

Note: If a schedule takes longer than the number of periods in the calendar, the values in the final calendar period will be used for all subsequent schedule periods.

Targets toolbar

The ![]() Targets subtab features the following controls:

Targets subtab features the following controls:

|

|

Start Date |

|

|

Generate Periods |

|

|

Manage Diggers

|

|

|

Add an extra period to the calendar

Note: This button will be dimmed if no periods have been added to your setup. Use the |

|

|

Delete currently selected period

Note: You can select multiple periods by pressing and holding Shift and selecting the periods you wish to delete. |

|

|

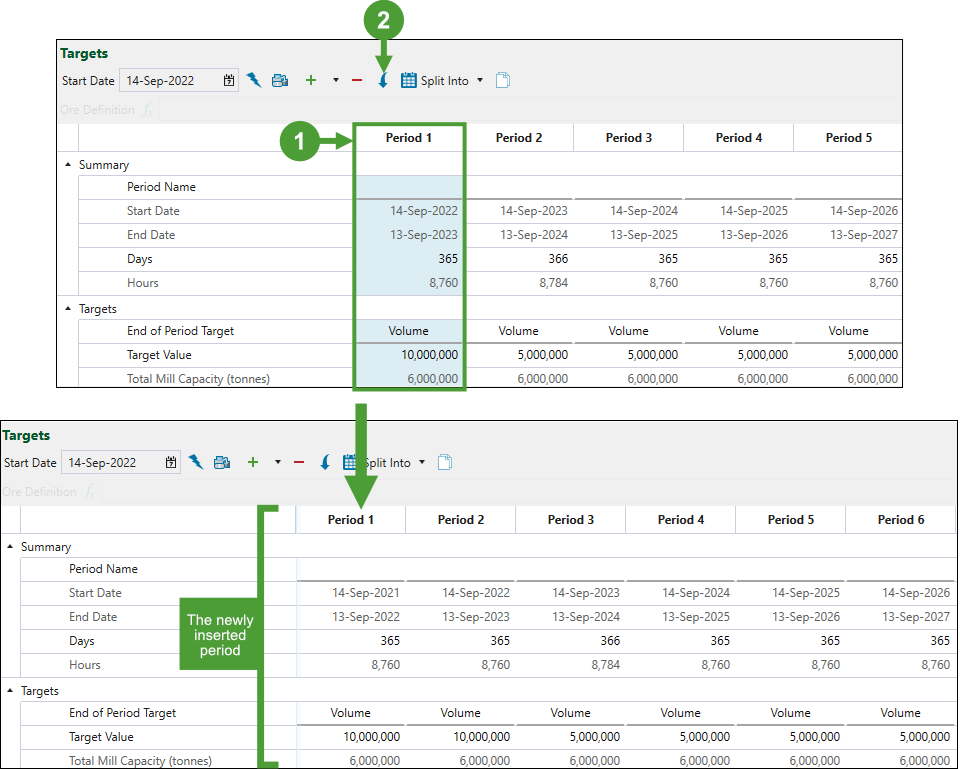

Insert period before selected period Note: The newly added period will have the same settings as the period it precedes.

To insert a new period, select the column corresponding to the period before which you wish a new period to be added. Next, click the |

|

|

Split into

Allows you to split the selected period to display the data on a monthly, quarterly, or semi-annual basis. |

|

|

Copy calendar to clipboard

|

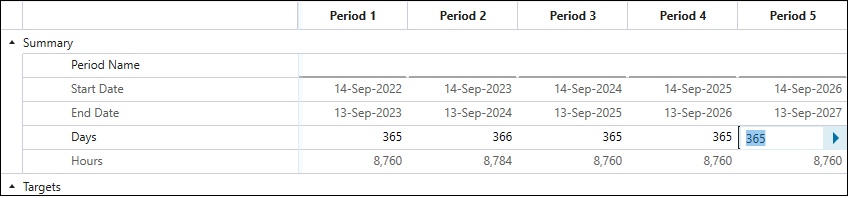

Summary

The Summary section of the table shows the time frames of each period in your setup. You can specify the number of days in a given period, and Evolution will automatically update the time frame during which the mining operations are to be performed in this period.

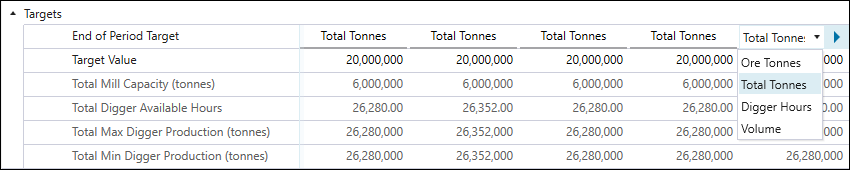

Targets

The Targets section allows you to set the target and the target value that must be met in a given period.

Note: While any returned schedule must meet the target that you set for each period (for hard constraints, periods can sometimes be ended before meeting the target), Evolution will attempt to generate schedules that also meet the other objectives.

You can select from the following target types:

-

Ore Tonnes: The returned schedule will ensure that all mills in the setup meet their capacities.

Note: Set the capacity and ore definition for each mill in the table in the Targets subtab.

-

Total Tonnes: The returned schedule will end the period once the total tonnes of ore and waste excavated from the pit and reclaimed from stockpiles in a given period meet the set target value.

-

Digger Hours: The returned schedule will end the period once all available digger hours are used in a given period. See Digger for more information.

Note: This target can be set only in the Material Movement schedules.

-

Haulage Hours: The returned schedule will end the period once all available truck hours are used in a given period.

Note: This target can be set only in the Equipment schedules.

-

Volume: The returned schedule will end the period once the total volume of ore and waste excavated from the pit in a given period meets the set target value.

An error will be returned if 20 or more periods from your schedule cannot meet the specified targets.

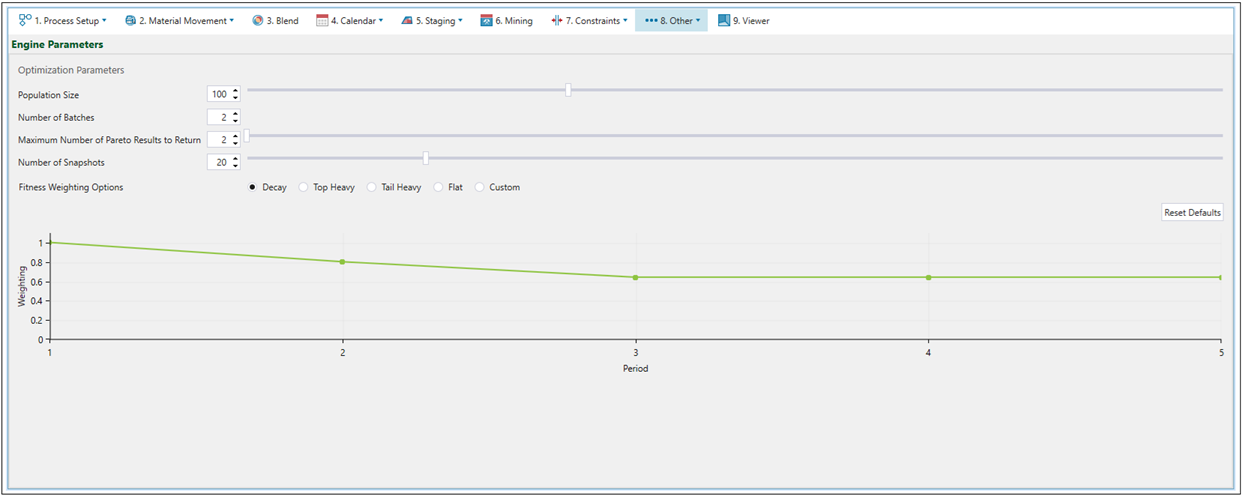

If you have set the Number of Batches to 2 in the

See Engine Parameters for more information.

If this occurs, you will need to either adjust your targets or relax your constraints until a solution can be found.

Evolution understands that the final period may not meet targets due to all minable material being extracted, so no error will be returned in this case.

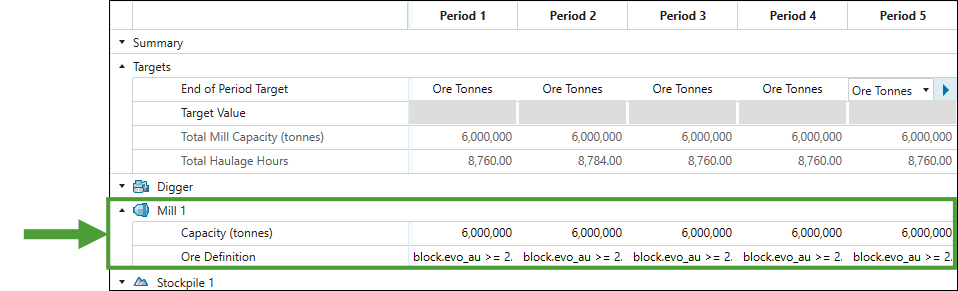

Resource targets

The ![]() Targets subtab also allows you to specify the parameters for diggers, mills, and stockpiles that have been added to your setup.

Targets subtab also allows you to specify the parameters for diggers, mills, and stockpiles that have been added to your setup.

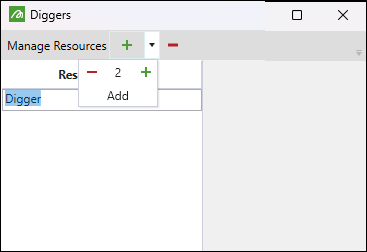

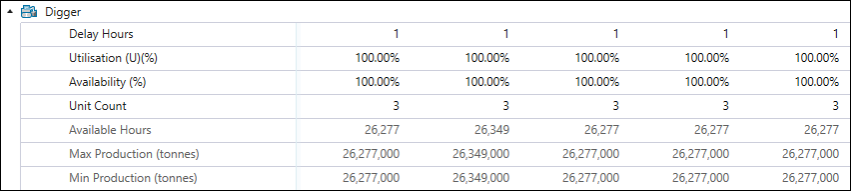

Digger

For each digger fleet you add, specify the Delay Hours, Utilisation, Availability, and Unit Count (the number of diggers in the fleet). The available hours of operation, and maximum and minimum production (in tonnes per period) will be automatically calculated based on the values you provide.

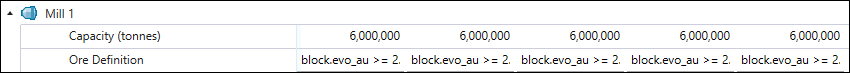

Mill

Enter a mill's capacity and ore definition on a per period basis. If you set Ore Tonnes as the end of period target, Evolution will end the period when all mills’ capacity is reached. The ore definition describes the type of material that can be processed by the mill. The formula below shows an example ore definition:

According to this definition, the mill can only process material with an ore grade greater or equal to 2.2 grams per tonne.

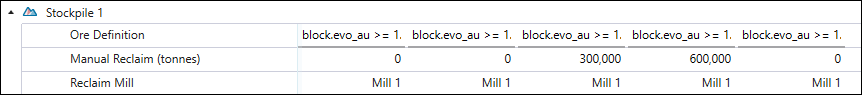

Stockpile

For each listed stockpile, define the following:

-

Ore Definition: Restricts the material going to a stockpile. This definition must be mutually exclusive to the ore definition provided for the mill. That is, no block should satisfy the definition for more than one destination, as Origin Blocks module uses these definitions to determine where the ore tonnes from each block should be sent. The only exception to this rule are schedule setups where both Blending as a secondary objective, and Dynamic Blending are enabled. See Blend for more information.

Note: If a mill has an overflow stockpile enabled, then any ore matching that mill’s ore definition in excess of its capacity in a given period will be sent to that stockpile. In the following periods, if there is not enough pit material passing the mill’s ore definition to meet the target capacity, ore will be automatically reclaimed from the stockpile, unless there are not enough truck hours available in the end of period target that you have set. If you want to give Origin a better chance to meet mill targets, you need to ensure that the mills have overflow stockpiles, and that their ore definitions are broad enough that there is a surplus of material to build them up.

-

Manual Reclaim: Specifies the maximum amount of material that can be sent from the stockpile to the associated mill.

-

Reclaim Mill: Specifies the mill associated with a given stockpile.