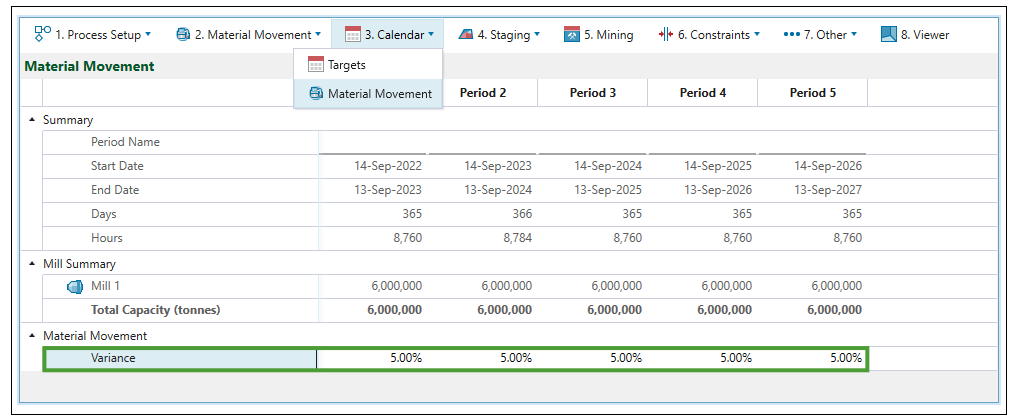

Material Movement

Source file: origin-block-setups-objectives-material-movement.htm

The ![]() Material Movement target is a variance that is set per period. It is used to control the allowable variance for each period of the schedule from the total material moved, total ore moved, and total equipment hours available in the calendar. A variance of 5% would allow any schedule between 95% and 105% on the calendar maximum to be regarded as not violating the given value. This is used to evaluate how well a given schedule utilised its mills and (or) diggers. Consequently, this value represents the degree of accuracy required when the software is aiming to meet the end of period targets set in the

Material Movement target is a variance that is set per period. It is used to control the allowable variance for each period of the schedule from the total material moved, total ore moved, and total equipment hours available in the calendar. A variance of 5% would allow any schedule between 95% and 105% on the calendar maximum to be regarded as not violating the given value. This is used to evaluate how well a given schedule utilised its mills and (or) diggers. Consequently, this value represents the degree of accuracy required when the software is aiming to meet the end of period targets set in the ![]() Calendar >

Calendar > ![]() Targets tab.

Targets tab.

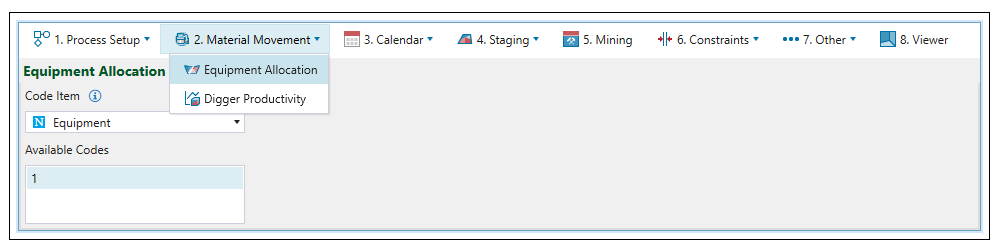

Equipment Allocation

Equipment Allocation

The ![]() Equipment Allocation subtab is used to add distinct regions in the model to the setup. They usually represent stages or lithologies. Once they are added, production rates per code can be defined in the

Equipment Allocation subtab is used to add distinct regions in the model to the setup. They usually represent stages or lithologies. Once they are added, production rates per code can be defined in the ![]() Digger Productivity subtab.

Digger Productivity subtab.

Digger Productivity

Digger Productivity

The ![]() Digger Productivity tab is used to define production rates per digger for each unique equipment code present in the Equipment Code variable set in the

Digger Productivity tab is used to define production rates per digger for each unique equipment code present in the Equipment Code variable set in the ![]() Equipment Allocation subtab.

Equipment Allocation subtab.

Calendar

Calendar

The ![]() Calendar >

Calendar > ![]() Material Movement objectives are used to control the variance tolerance for each period of the schedule. Evolution uses the variance to control how hard the scheduler must work during each period to achieve the movement target. A higher percentage number will generate a lower fitness, whereas a lower percentage variance will result in the scheduler refining the result based on a higher fitness value.

Material Movement objectives are used to control the variance tolerance for each period of the schedule. Evolution uses the variance to control how hard the scheduler must work during each period to achieve the movement target. A higher percentage number will generate a lower fitness, whereas a lower percentage variance will result in the scheduler refining the result based on a higher fitness value.