Mining

Source file: origin-block-setups-mining.htm

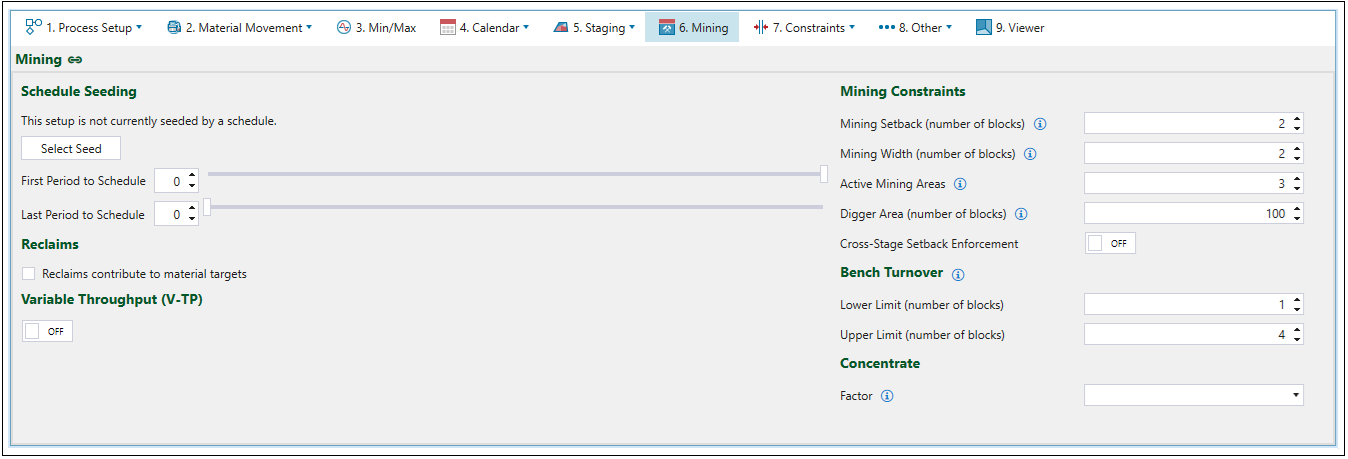

The ![]() Mining tab allows you to apply settings in the six separate sections..

Mining tab allows you to apply settings in the six separate sections..

Schedule Seeding

You can derive new schedules from previously created schedules using Evolution’s seeding mechanism. After selecting an existing schedule via the Select Seed button, specify the First Period to Schedule and the Last Period to Schedule. The parameters from the seed schedule you have selected will be used for scheduling before the selected start period.

-

Click the Change Seed button to assign a new schedule as a seed schedule.

-

Click the Remove Seed button to delete schedule seeding.

Reclaims

Selecting the Reclaims contribute to material targets checkbox allows you to include the reclaimed mass when applying the material targets. The operation will be different based on the checkbox selection status:

-

Selected: Mining will stop when the amount of material that has come from the pit reaches the target.

-

Not selected: Both the material coming from the pit and from the reclaims will contribute to reaching the set target.

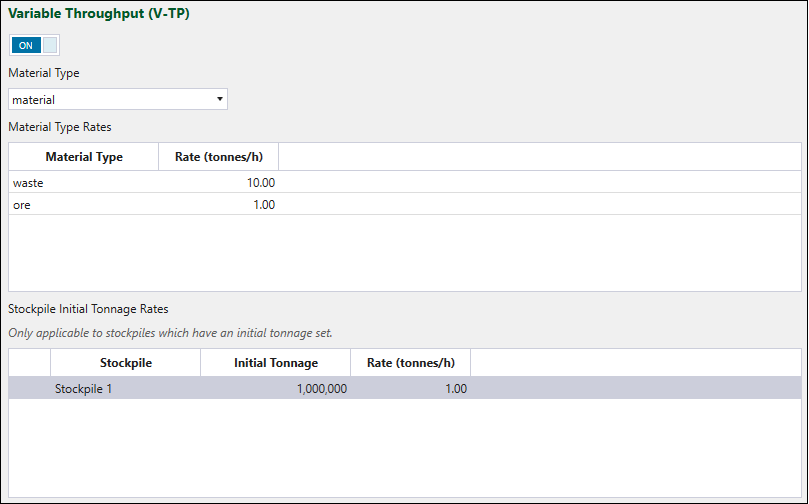

Variable Throughput (V-TP)

Use the Variable Throughput to base the mill capacity on the total crushing hours available in a period instead of on the ore tonnage. To set up the Variable Throughput, click the toggle button to enable this function. Next, select the required attribute from the Material Type drop-down, specify the rate (tonnes per hour) for each material type. The content of the Stockpile Initial Tonnage Rates table will reflect the stockpile initial tonnage settings that you have applied in the ![]() Configuration subtab (see Configuration for more information).

Configuration subtab (see Configuration for more information).

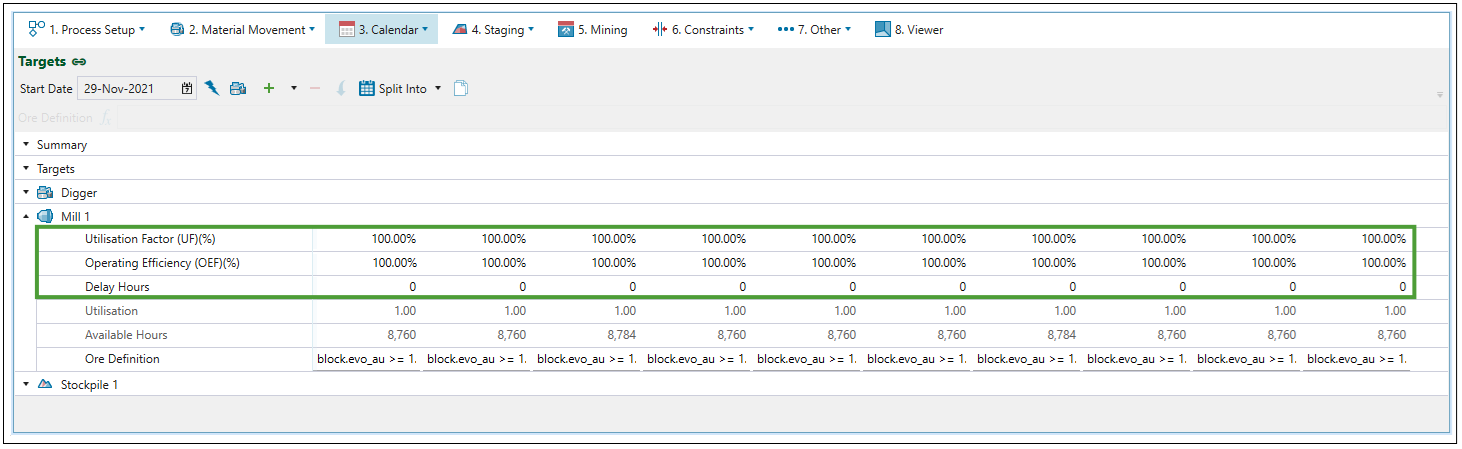

If you enable Variable Throughput, you will have to enter the Utilisation Factor, Operating Efficiency, and Delay Hours for the mill in the ![]() Calendar >

Calendar > ![]() Targets subtab.

Targets subtab.

Mining Constraints

You can set up the following mining constraints:

Note: These constraints are hard constraints. See Constraints for more information on the constraints that you can add to your Origin Blocks setup.

Mining Setback

Mining Setback is the minimum number of blocks back from any block that you want to mine.

Example: If you set Mining Setback to 3, the face of the bench above must be 3 blocks back from any block you want to mine. Partial mining cannot occur, as it has been specified that the active face of at least three blocks needs to be exposed once mining in that bench takes place.

Note: The term face refers to the vertical wall of the bench, and the term active faces means the number of faces that are being worked on in the pit at a given time.

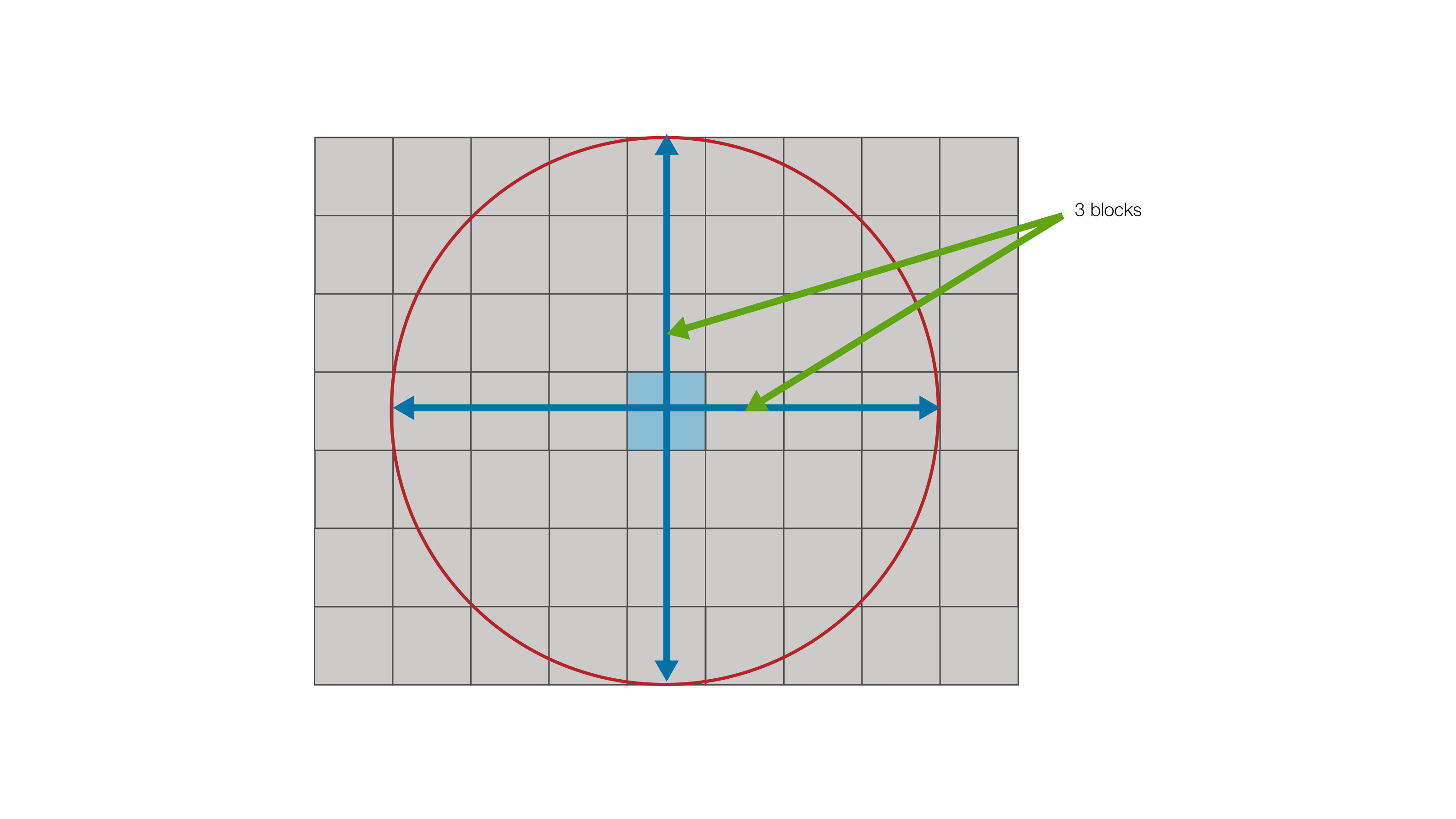

Mining Width

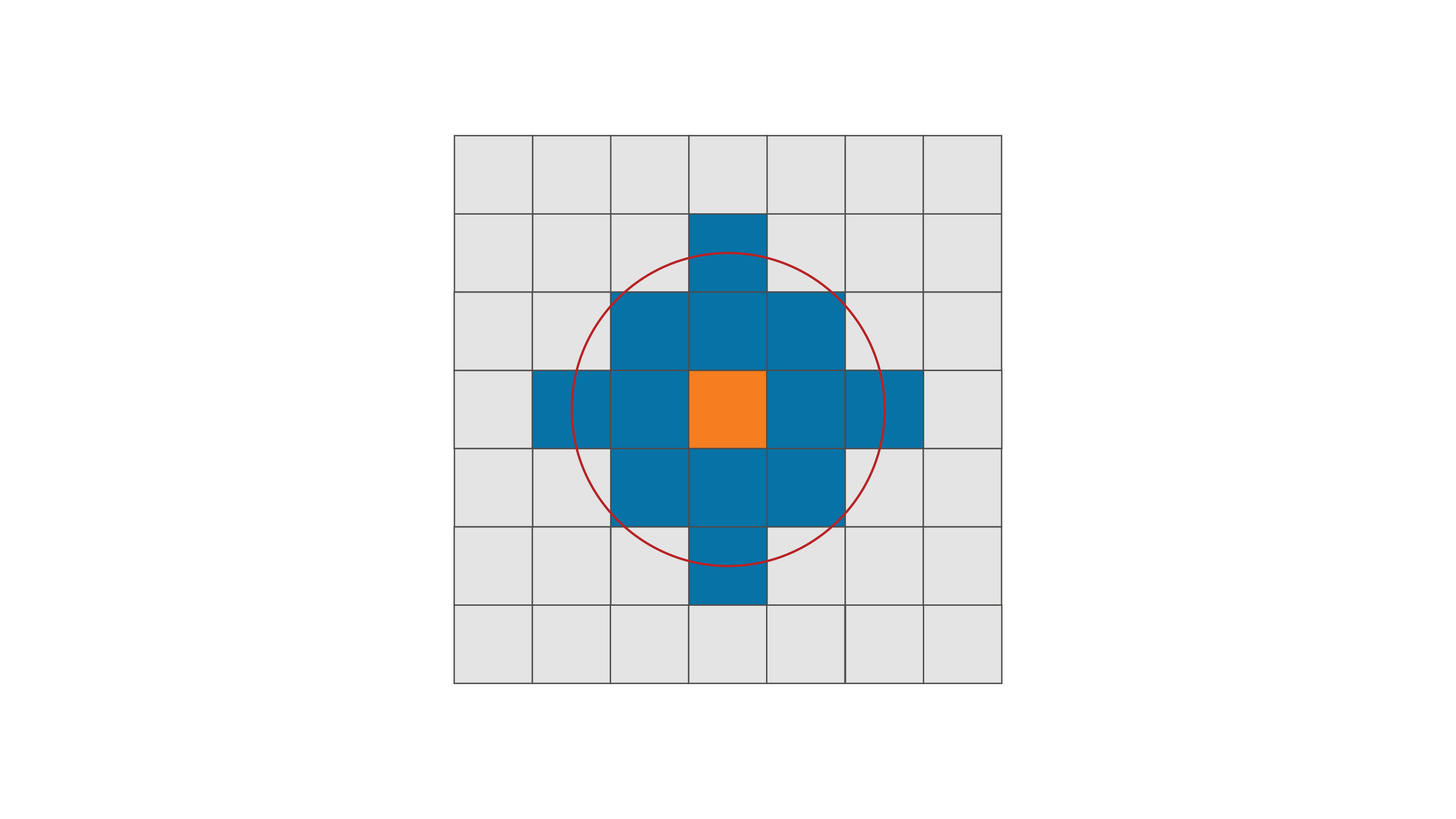

Use Mining Width to set the minimum space (specified by the number of blocks) required to access a new bench. The mining width, which is applied as a radius, is the product of the size of the block and the number of blocks, as shown on the image below.

Active Mining Areas

In Origin Blocks, a digger is moved to a location, and then allowed to mine within a given radius. The Active Mining Areas constraint sets the number of areas where the blocks are being mined at a given time.

Digger Area

The Digger Area constraint sets the number of blocks to be mined from an active area before a digger can be moved. This setting ensures the mining sequence can be practically achieved without requiring the mining fleet to be constantly relocated.

Cross-Stage Setback Enforcement

When you enable Cross-Stage Setback Enforcement, Evolution will check if there are any setback violations for blocks from all stages (instead of checking only the current blocks' stage).

Bench Turnover

The Bench Turnover inputs control how each bench within a stage is developing vertically. The higher the upper limit, the faster the mining will progress vertically towards the ore.

Note: The default Lower Limit and Upper Limit setting ratio is 1 to 4.

To develop the schedule in large flat benches, enter lower values for both limits (for example, 1 and 2). On the contrary, to increase the vertical progress, enter larger numbers for both limits (for example, 10 and 100).

Concentrate

Concentrate is a factor that is applied to mill and parcel tonnages on mining. Therefore, it can be used in an Equipment (truck hours) schedule when the mill is targeting an item other than tonnes. The resulting tonnage will affect haulage hours.

Concentrate factor allows you to backcalculate the ore tonnes by multiplying the scheduling item and the Concentrate factor attribute (selected from the drop-down menu) to ensure the cycle times of trucks are based on ore tonnes.

Example: If the total mass extracted from a single Block A equals 1000 tonnes, with 200 tonnes of Ore A, and 300 tonnes of Ore B, then the waste extracted from that block would equal 500 tonnes. If 50% of the extracted material was sent to the mill and the other 50% to waste, you could use the following factor:

The example above describes the calculation for a single block in a setup. If there is no existing concentration factor in the setup, and a flat value across all blocks is appropriate, you can apply a concentrate factor for all blocks in your model using maths scripts (see Applying a Maths Script for more information).