Screening Stations

Source file: origin-reserve-setups-flowchart-screen-stations.htm

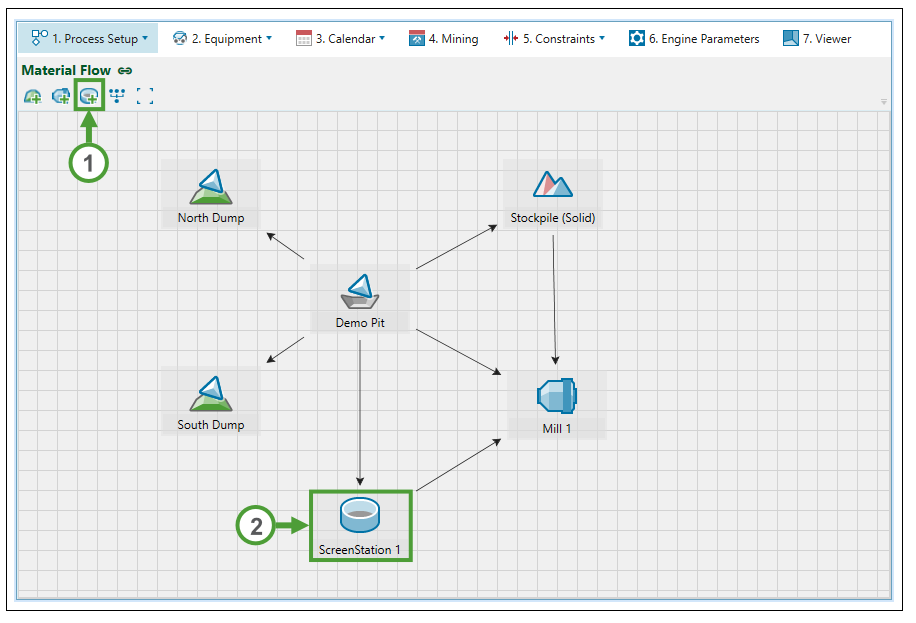

Screening stations are used to separate material into product and waste. To use this tab, screen stations need to be added to the setup in the ![]() Material Flow subtab.

Material Flow subtab.

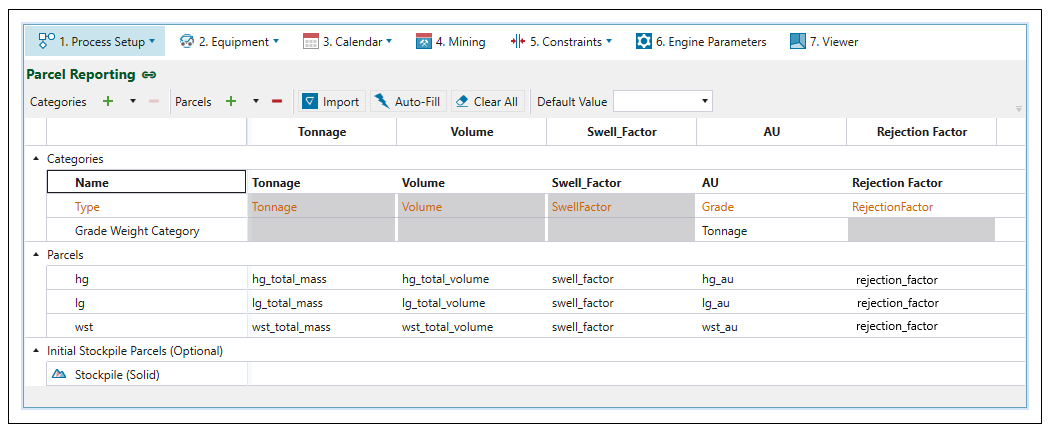

Grade categories also need to be defined in the ![]() Process Setup >

Process Setup > ![]() Parcel Reporting tab. A Rejection Factor should also be added. It is a value between 0.0 and 1.0 that defines how much material is not processed by the screening station.

Parcel Reporting tab. A Rejection Factor should also be added. It is a value between 0.0 and 1.0 that defines how much material is not processed by the screening station.

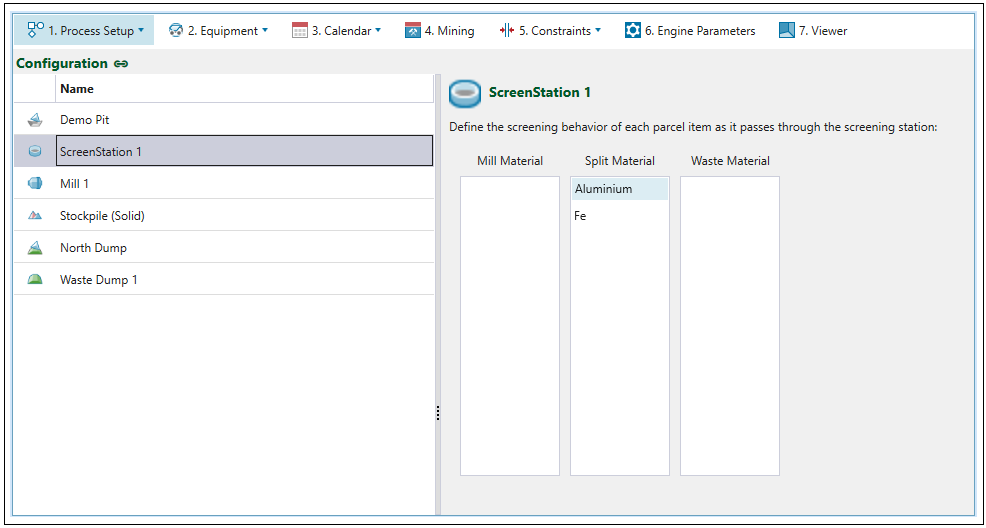

In the ![]() Process Setup >

Process Setup > ![]() Configuration tab, the material processed by the screen station can categorised the following ways:

Configuration tab, the material processed by the screen station can categorised the following ways:

- Mill material: Material is sent directly to the mill.

- Split material: Material split by the Rejection Factor and then sent to the mill or waste dump.

- Waste material: Material is sent directly to the waste dump.

In the ![]() Process Setup >

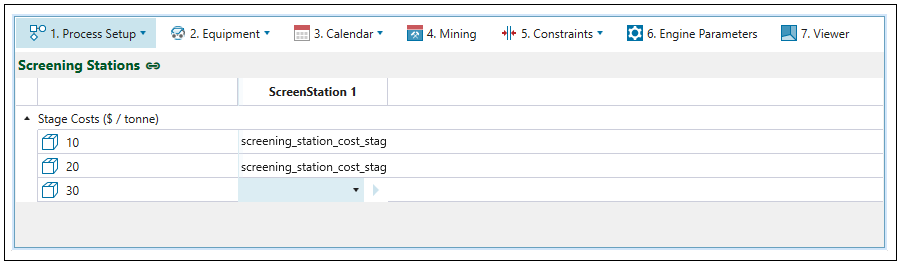

Process Setup > ![]() Screening stations subtab, you can define the value of sending material from a particular stage in the model to a screening station included in the setup. To set the cost, use the attributes from the reserve model. This step is optional.

Screening stations subtab, you can define the value of sending material from a particular stage in the model to a screening station included in the setup. To set the cost, use the attributes from the reserve model. This step is optional.

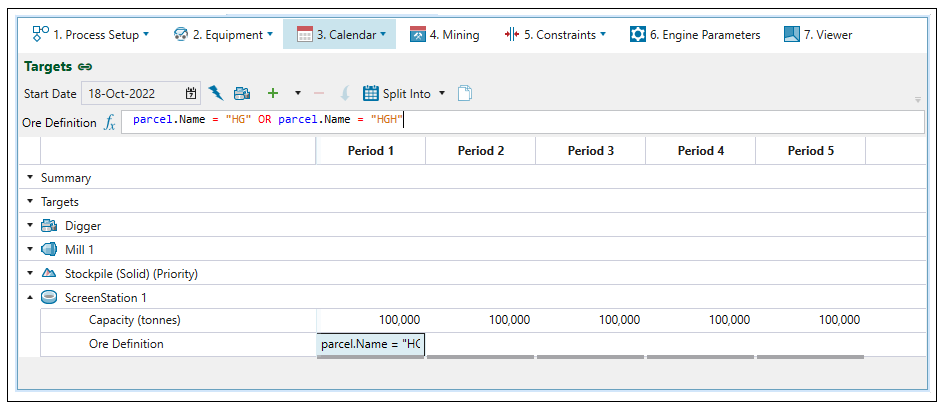

Once you configure the screening station, you can define what kind of material can be processed in it. To do so, go to the ![]() Calendar >

Calendar > ![]() Targets subtab and specify the Ore Definition field. The ore definition is parcel-based.

Targets subtab and specify the Ore Definition field. The ore definition is parcel-based.

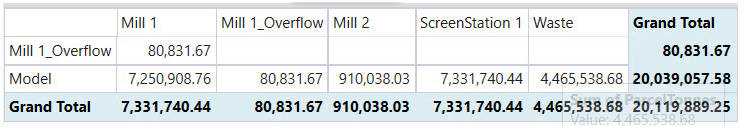

Once you run your setup and download the resulting schedule, you can create a pivot report to visualise the amount of material processed by the screening station. See Pivot Reporting for more information.