Material Movement

Source file: origin-block-setups-objectives-material-movement.htm

Use the  Material Movement tab to allocate equipment and to specify production rates for each digger in your setup. Material Movement setups also contain the

Material Movement tab to allocate equipment and to specify production rates for each digger in your setup. Material Movement setups also contain the  Material Movement subtab, nested under the

Material Movement subtab, nested under the ![]() Calendar tab, where you can specify mill capacity and its variance.

Calendar tab, where you can specify mill capacity and its variance.

Equipment Allocation

Use the ![]() Equipment Allocation subtab to add distinct regions in the model to the setup. These regions usually represent stages or lithologies and once you add them, you will be able to define production rates per code in the

Equipment Allocation subtab to add distinct regions in the model to the setup. These regions usually represent stages or lithologies and once you add them, you will be able to define production rates per code in the ![]() Digger Productivity subtab.

Digger Productivity subtab.

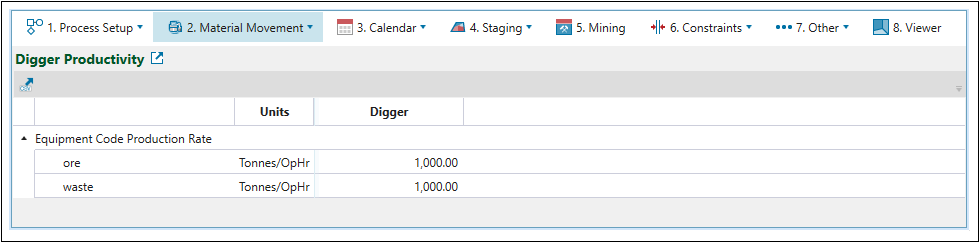

Digger Productivity

Use the  Digger Productivity subtab to define production rates per digger for each unique equipment code that you have set in the

Digger Productivity subtab to define production rates per digger for each unique equipment code that you have set in the ![]() Equipment Allocation subtab.

Equipment Allocation subtab.

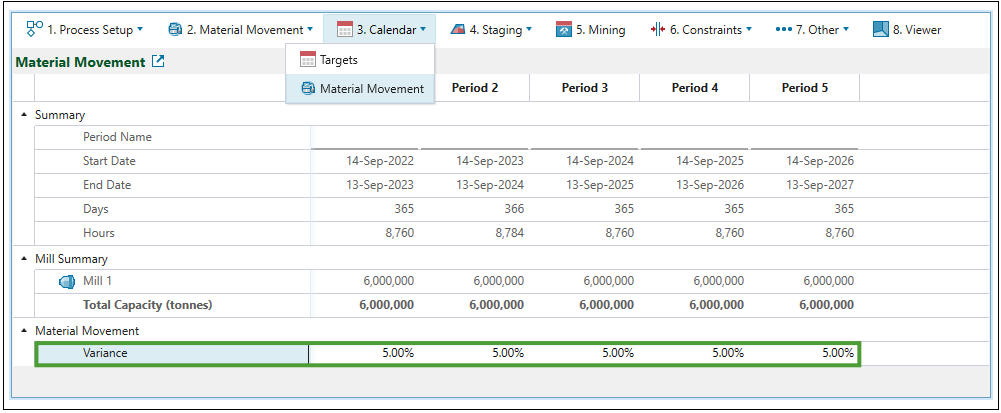

Material Movement in the Calendar

Use the  Material Movement subtab in the

Material Movement subtab in the ![]() Calendar to set the total capacity of mills in your setup and to control the mill capacity variance in material movement (total material moved, total ore moved, and total equipment hours available in the calendar) in each period of the schedule.

Calendar to set the total capacity of mills in your setup and to control the mill capacity variance in material movement (total material moved, total ore moved, and total equipment hours available in the calendar) in each period of the schedule.

A variance of 5% would allow any schedule between 95% and 105% on the calendar maximum to be regarded as not violating the given value. Consequently, variance represents the degree of accuracy required when Evolution is aiming to meet the end of period targets that you set in the