Configuration

Source file: strategy-setups-economic-model-configuration.htm

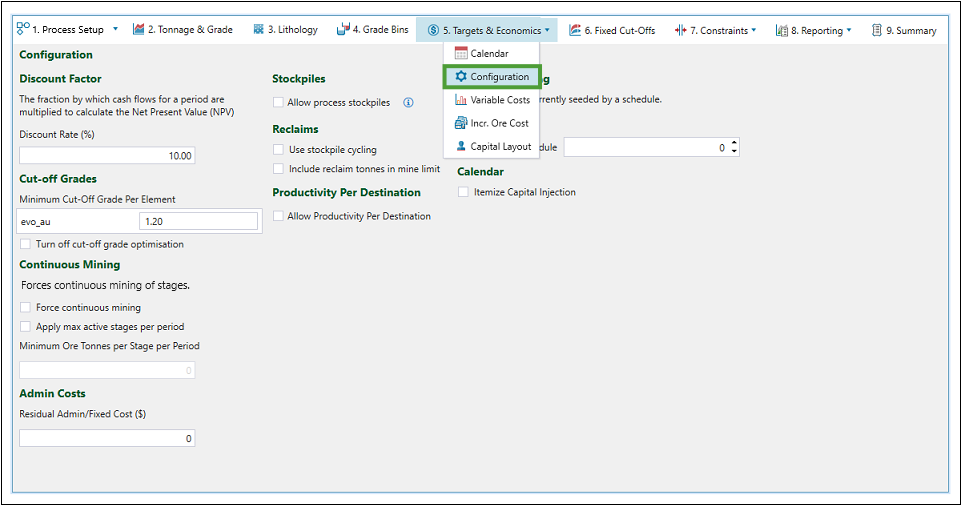

The ![]() Configuration subtab allows you to edit the calendar configuration. To enter this subtab, go to the Targets & Economics tab and select

Configuration subtab allows you to edit the calendar configuration. To enter this subtab, go to the Targets & Economics tab and select ![]() Configuration from the drop-down list.

Configuration from the drop-down list.

This screen allows you to configure the following settings:

- Discount Factor

- Cut-off Grades

- Continuous Mining

- Admin Costs

- Stockpiles

- Reclaims

- Productivity Per Destination

- Schedule Seeding

- Calendar

Discount Factor

Use the Discount Factor section to set the Discount Rate (%) for calculating the net present value (NPV).

Cut-off Grades

Strategy optimises the NPV and blends (if the blends are used). One of the main outputs of the engine is the cut-off grades that will produce the optimal NPV and blend. In this section, you can specify the minimum cut-off grade per element. Tonnes below this grade will be sent to the waste dumps. You can turn off cut-off grade optimisation by selecting the Turn off cut-off grade optimisation checkbox .

Continuous Mining

Continuous mining refers to the state when all stages are mined continuously in a schedule. This section allows you to set the two following continuous mining options:

-

Force continuous mining. Select this checkbox to force Evolution to create a schedule where all of the stages are mined continuously. More specifically, Evolution will not open a new stage unless it is impossible to mine from an already open stage. You can check the output of this restriction in the Stages tab in the final schedule report.

NoteEvolution will only enforce this option if all of the setup constraints are satisfied. If a constraint is broken while the stages are being mined continuously, Evolution may open a new stage.

For example:

A constraint in which Evolution can only mine a proportion of the benches in a stage per period has been set. If the schedule achieves this number before the end of the period, Evolution will open a new stage, despite not having finished mining the first stage. -

Apply max active stages per period. Select this checkbox to force Evolution to mine the maximum number of stages per period, provided the minimum ore tonnes value is met for each stage. You can enter the desired value into the Minimum Ore tonnes per Stage per Period field to specify the minimum ore tonnes per stage in each period.

Admin Costs

You can define the amount of general and administrative costs per period, which are required to run an operation, in the Targets & Economics > ![]() Calendar subtab. However, in order to define admin costs per period, Residual Admin/Fixed Cost ($) has to be defined first in the configuration. This cost will replace the admin cost provided in the

Calendar subtab. However, in order to define admin costs per period, Residual Admin/Fixed Cost ($) has to be defined first in the configuration. This cost will replace the admin cost provided in the ![]() Calendar subtab when pit material is depleted and the setup enters reclaim mode (the result can be seen in the schedule report).

Calendar subtab when pit material is depleted and the setup enters reclaim mode (the result can be seen in the schedule report).

In order to enter "reclaim only" mode, the setup needs to have stockpiles with at least the same capacity as the process. Stockpiles can be added either as overflow in the ![]() Configuration subtab or as components in the

Configuration subtab or as components in the ![]() Material Flow subtab.

Material Flow subtab.

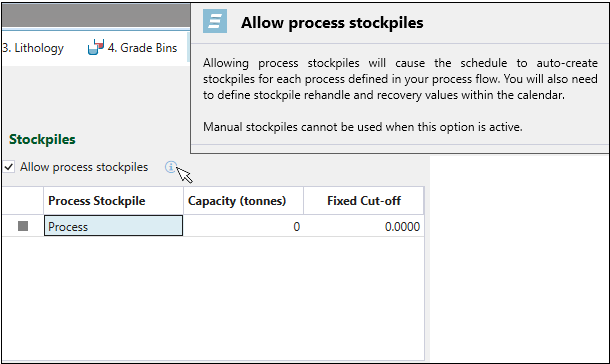

Stockpiles

If you want to create overflow stockpiles adjacent to each process, select the Allow process stockpiles checkbox. Next, define the capacity and fixed cut-off for each Process Stockpile. To get the additional information on the whole operation, hover over the  icon.

icon.

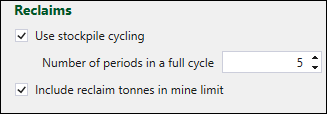

Reclaims

Reclaim tonnes can be included in the final mined tonnes of a schedule. If the Include reclaim tonnes in mine limit checkbox is selected, the setup must include stockpiles. Stockpiles can be added in the ![]() Material Flow subtab or in the Stockpiles section of the current subtab.

Material Flow subtab or in the Stockpiles section of the current subtab.

When you select the Use stockpile cycling checkbox, the Include reclaim tonnes in mine limit option will be selected automatically (as the stockpile reclaims happen at the start of the period), and you need to specify the time frame in the Number of periods in a full cycle field.

For example, when the full cycle is five years, and, consequently, the entered Number of periods in a full cycle is 5, 1/5 of the stockpile material will be taken at the start of each year of this full cycle.

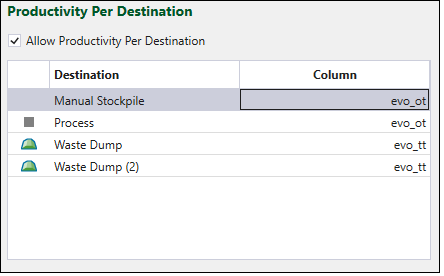

Productivity Per Destination

Productivity hours can be modelled as part of strategic optimisation. To do so, select the Allow Productivity Per Destination checkbox, and assign a productivity variable (provided by the block model included in your setup) to each destination.

Note: For this section to be included, the setup must have a waste dump, which is added in the ![]() Material Flow subtab.

Material Flow subtab.

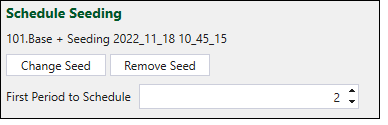

Schedule seeding

You can derive new schedules from previously created schedules using Evolution’s seeding mechanism. After selecting an existing schedule via the Select Seed button, specify the First Period to Schedule. The parameters from the selected seed schedule will be used for scheduling before the selected start period.

Your selection will be applied in the table that is displayed in the ![]() Calendar subtab.

Calendar subtab.

Note: The data of the seeded period is dimmed as it cannot be edited.

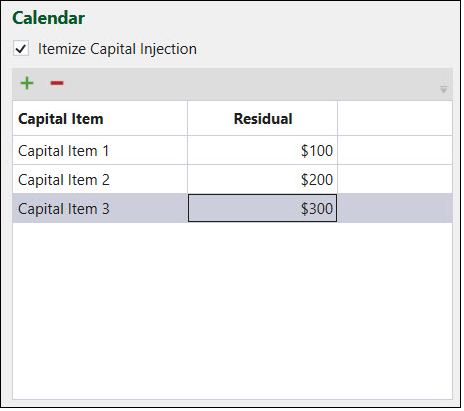

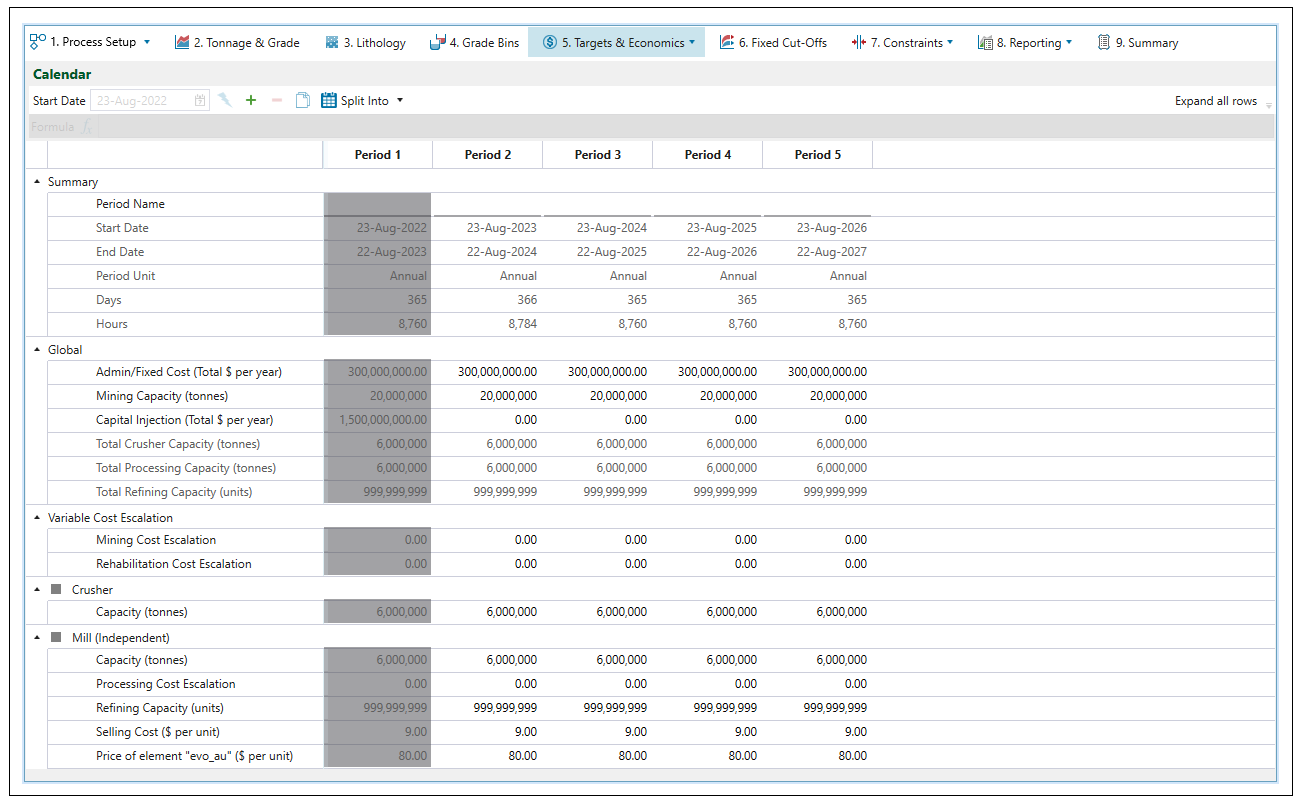

Calendar

The Itemize Capital Injection checkbox allows you to break down the information on the residual costs that occur in periods that follow the depletion of the pit. Once the pit has been completely mined, site operation can change to "reclaim only" mode, which means that there can be a few periods when only the stockpile is reclaimed. These residual costs are applied to every period where the pit has been depleted and the site operation is in "reclaim only" mode. The items listed under Itemize Capital Injection will be added to the Calendar subtab, where you need to manually specify the operating residual costs for the applicable periods.