Fields

Source file: strategy-setups-reporting.htm

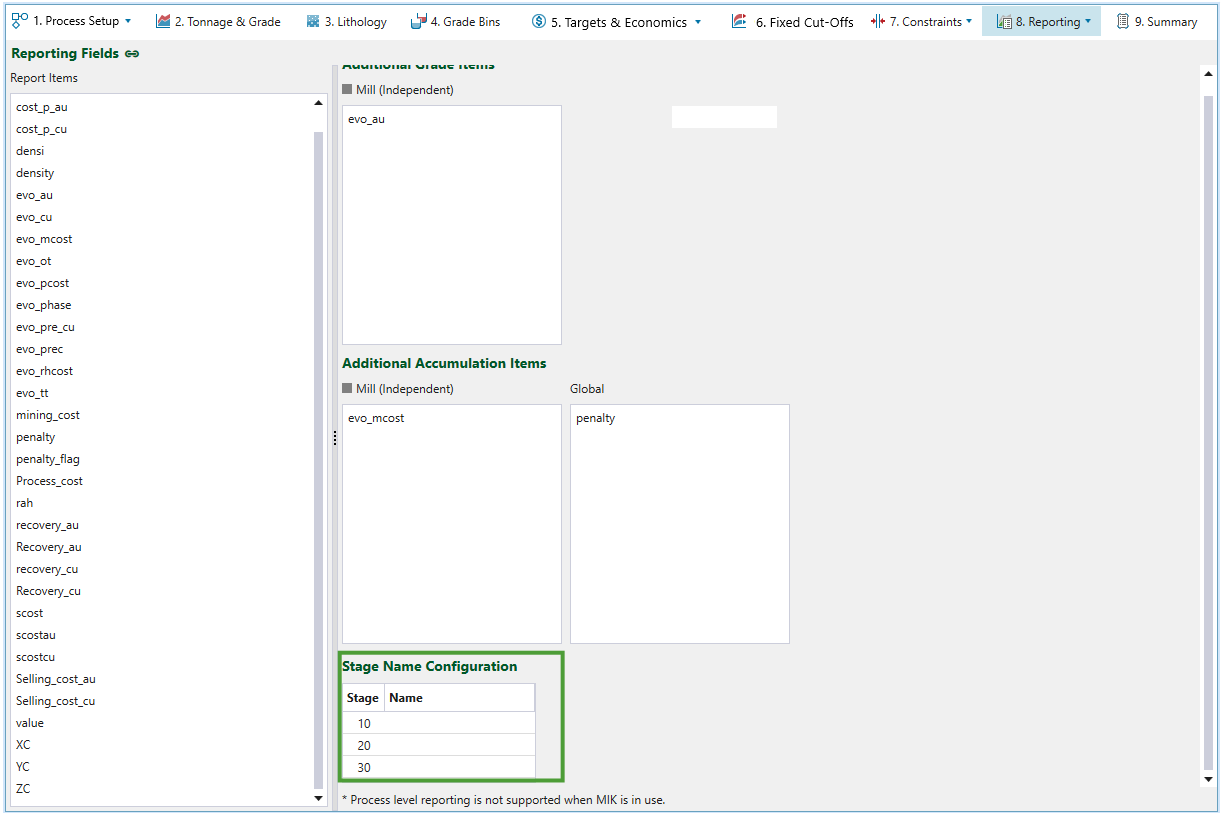

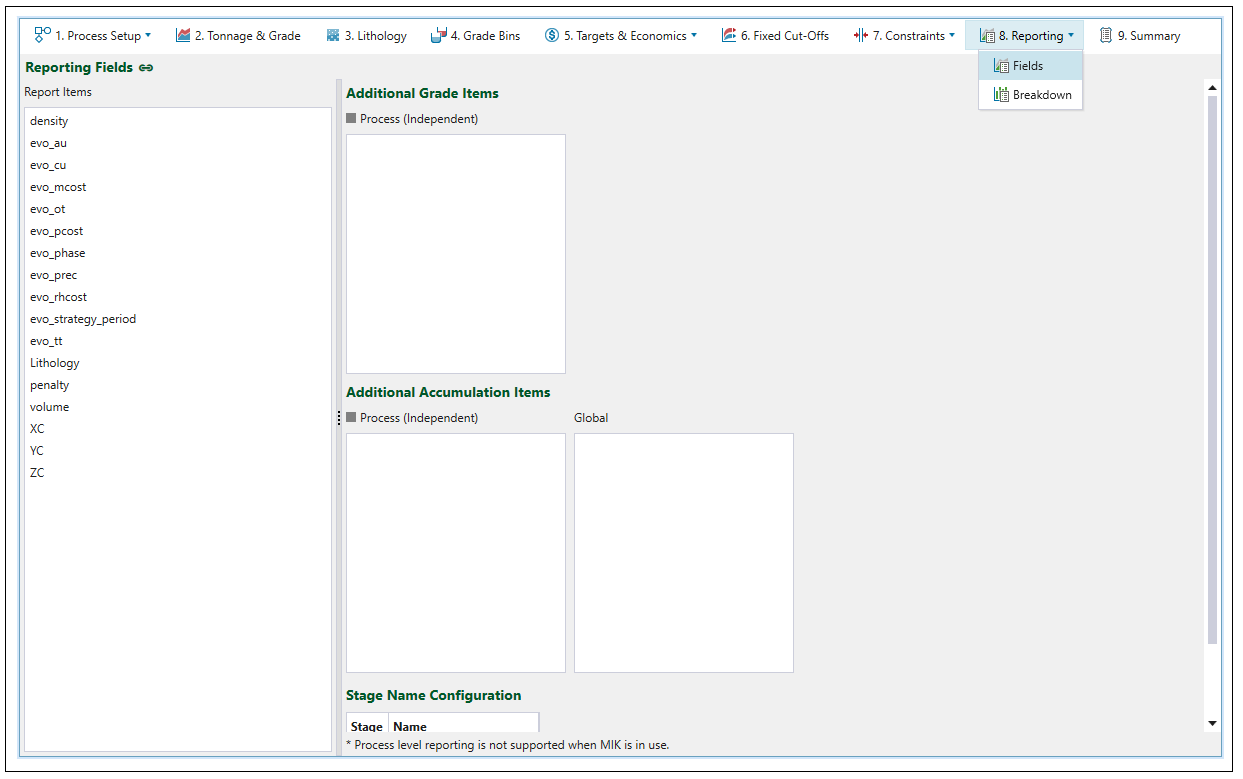

By default, the report includes, but is not limited to, a primary grade item, ore tonnes, and total tonnes, which are based on the specified elements and are all reported automatically. These elements are set in the ![]() Tonnage & Grade tab. The

Tonnage & Grade tab. The ![]() Fields subtab, which is nested under the

Fields subtab, which is nested under the ![]() Reporting tab, allows you to include additional attributes (pit model variables) in the Strategy result reports and pivots.

Reporting tab, allows you to include additional attributes (pit model variables) in the Strategy result reports and pivots.

The additional variables that can be added to the report are Grade Items and Accumulation Items.

-

Grade Items represent the grade of a metal, contaminants (etc.) in a given mass of material. For example, according to the formula where metal = grade * mass, a block of rock that weighs 1 tonne and has 100g of gold in it, has a grade of .0001. Grade items are weight-averaged by mass.

-

Accumulation Items represent block attributes that are aggregated and summed like the block mass. The example variables for accumulation items are ore tonnes and total tonnes of material.

When you go to the the ![]() Reporting tab >

Reporting tab > ![]() Fields, you can assign the Report Items (variables displayed on the right side of your screen) to the Additional Grade Items and Additional Accumulation Items list. To do so, drag and drop the required items into the appropriate fields.

Fields, you can assign the Report Items (variables displayed on the right side of your screen) to the Additional Grade Items and Additional Accumulation Items list. To do so, drag and drop the required items into the appropriate fields.

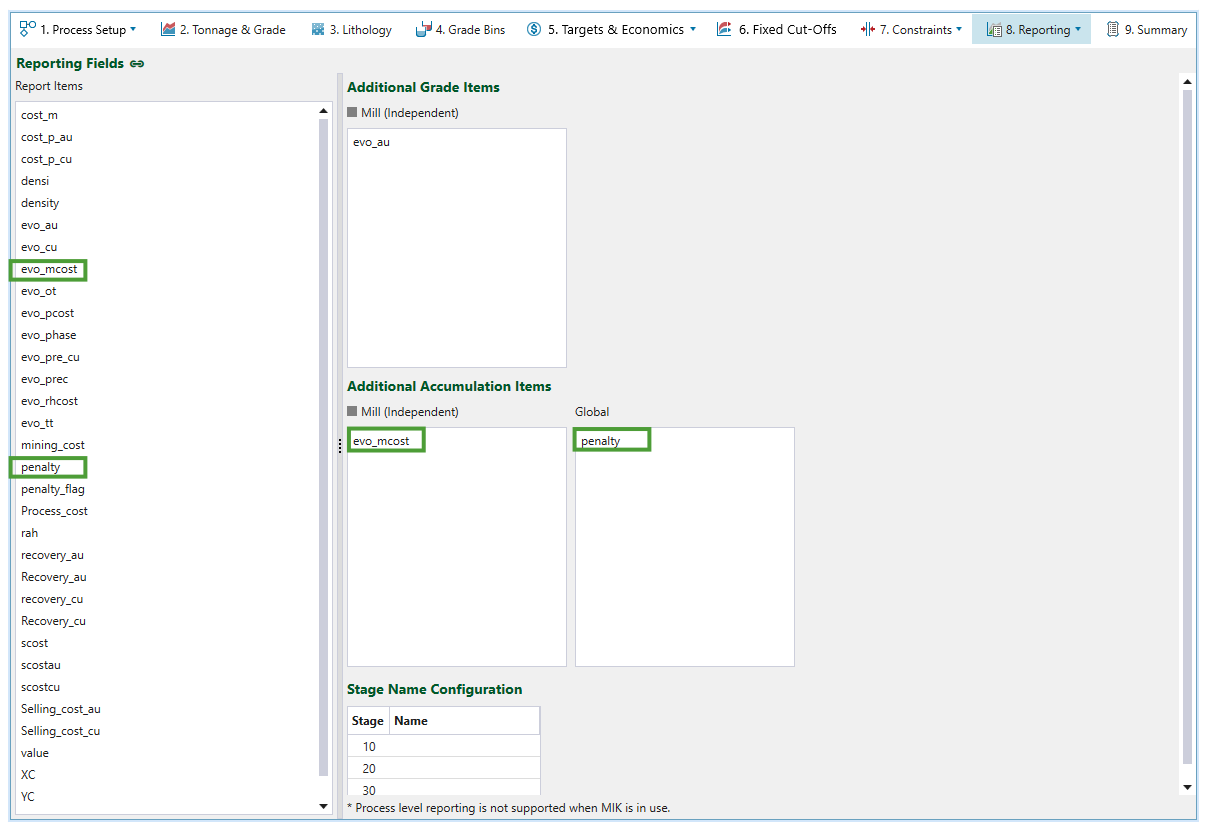

Additional Accumulation Items to be reported are divided into Process (Independent) and Global items.

-

Process (Independent) items

These items are related to the material that is fed to a process. While mining a stage or bench, if the block of material has any ore mass that is sent to process, the value of the reporting item from the block model is attached to that material. If that material is redirected to waste, or stockpile (etc.), the reporting item is split in ratio according to the flow of ore mass.

-

Global items

These items are related to all material in the process of mining a stage or bench, not just to the material that is fed to a process. When the material is split and sent to different destinations, the global reporting item is split in ratio with the mass of the component blocks and reported on. The breakdown of a report allows you to check how much material has been sent to each process (or to waste).

Additional accumulation items assigned on the Reporting Fields page should correspond to these specified for each constraint in your setup. See Constraints for more information.

Some constraints have a defined type of accumulation, and, consequently, items assigned to these constraints also belong to the corresponding accumulation type. The following table lists the constraints with the specified type of accumulation:

| Constraint | Accumulation type |

|---|---|

| Ore Exposure | Global |

| Global Accumulation | Global |

| Stage Accumulation | Global |

| Pit Accumulation | Global |

| Process Blend | Process |

| Process Accumulation | Process |

Note: The same accumulation item cannot be assigned to both Global and Process fields.

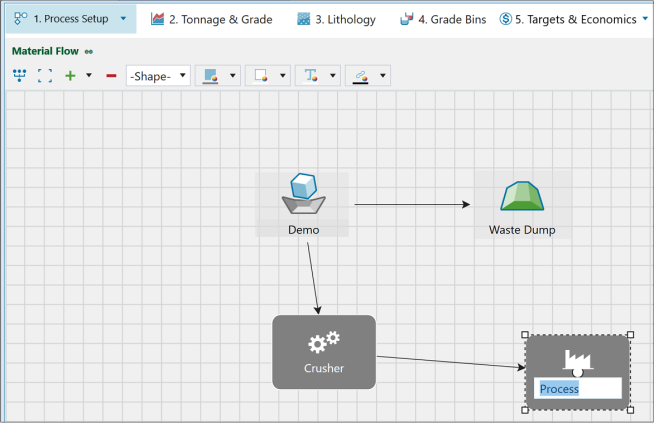

The Process (Independent) designation corresponds to a mill, i.e. it is a plant in which the ore is treated and the metals are recovered or prepared for smelting. It is the default name that can be changed the following ways:

-

By double-clicking on the name in the

Material Flow subtab:

Material Flow subtab:

-

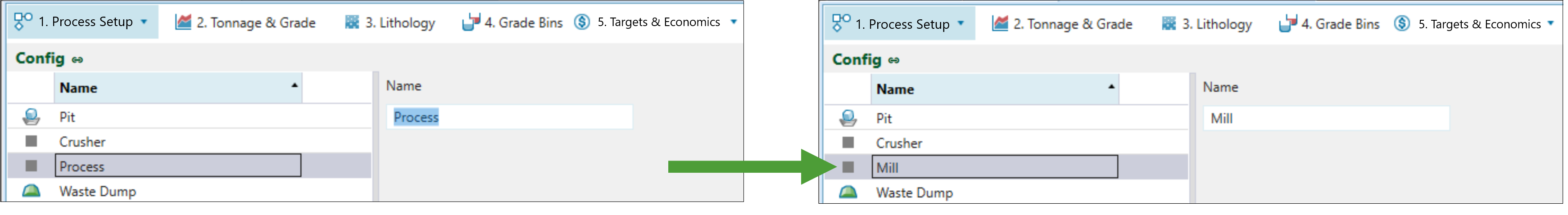

By changing the name in the

Process Setup >

Process Setup >  Configuration subtab:

Configuration subtab:

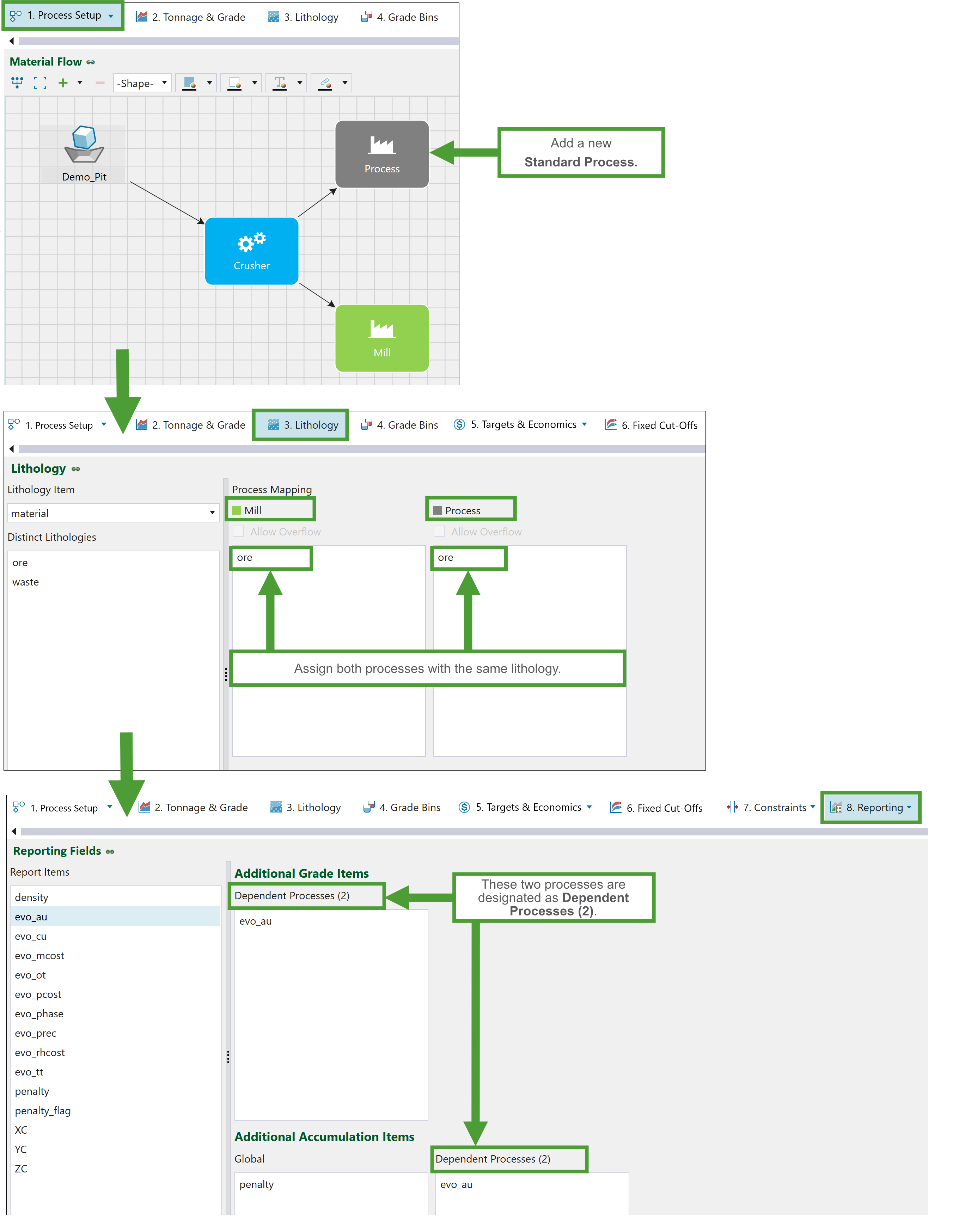

Note: You can also create dependent processes. To do so, add another Standard Process in the ![]() Process Setup tab. Any two processes that share at least one lithology are dependent, and they will be displayed as Dependent Processes (2) in the

Process Setup tab. Any two processes that share at least one lithology are dependent, and they will be displayed as Dependent Processes (2) in the ![]() Fields subtab. The number in the brackets indicates the number of dependent processes.

Fields subtab. The number in the brackets indicates the number of dependent processes.

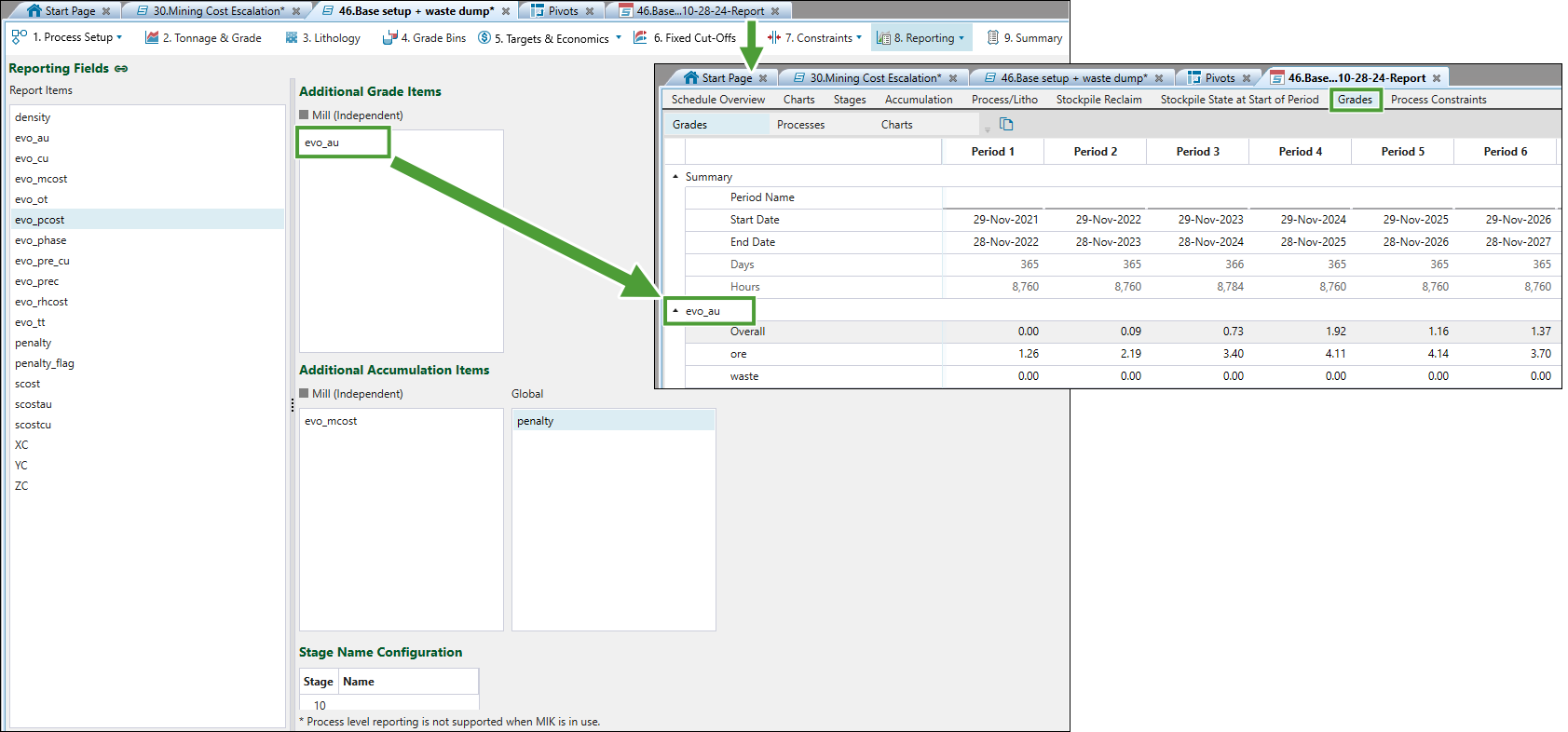

To add reporting items, drag model items such as grade attributes into the Additional Grade Items and tonnage into the Additional Accumulation Items list.

Grade items are also added to the Grades tab in the schedule report.

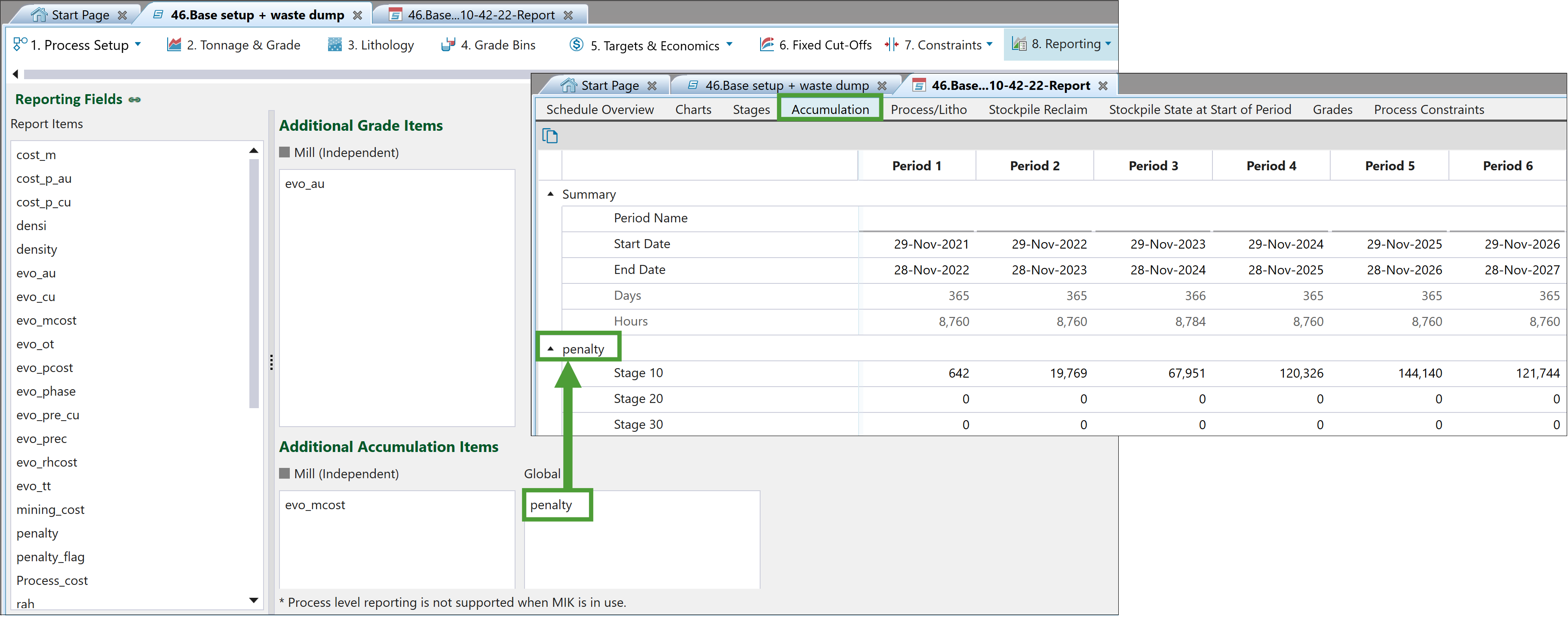

Items added to the Global section can be viewed under the Accumulation tab in the schedule report.

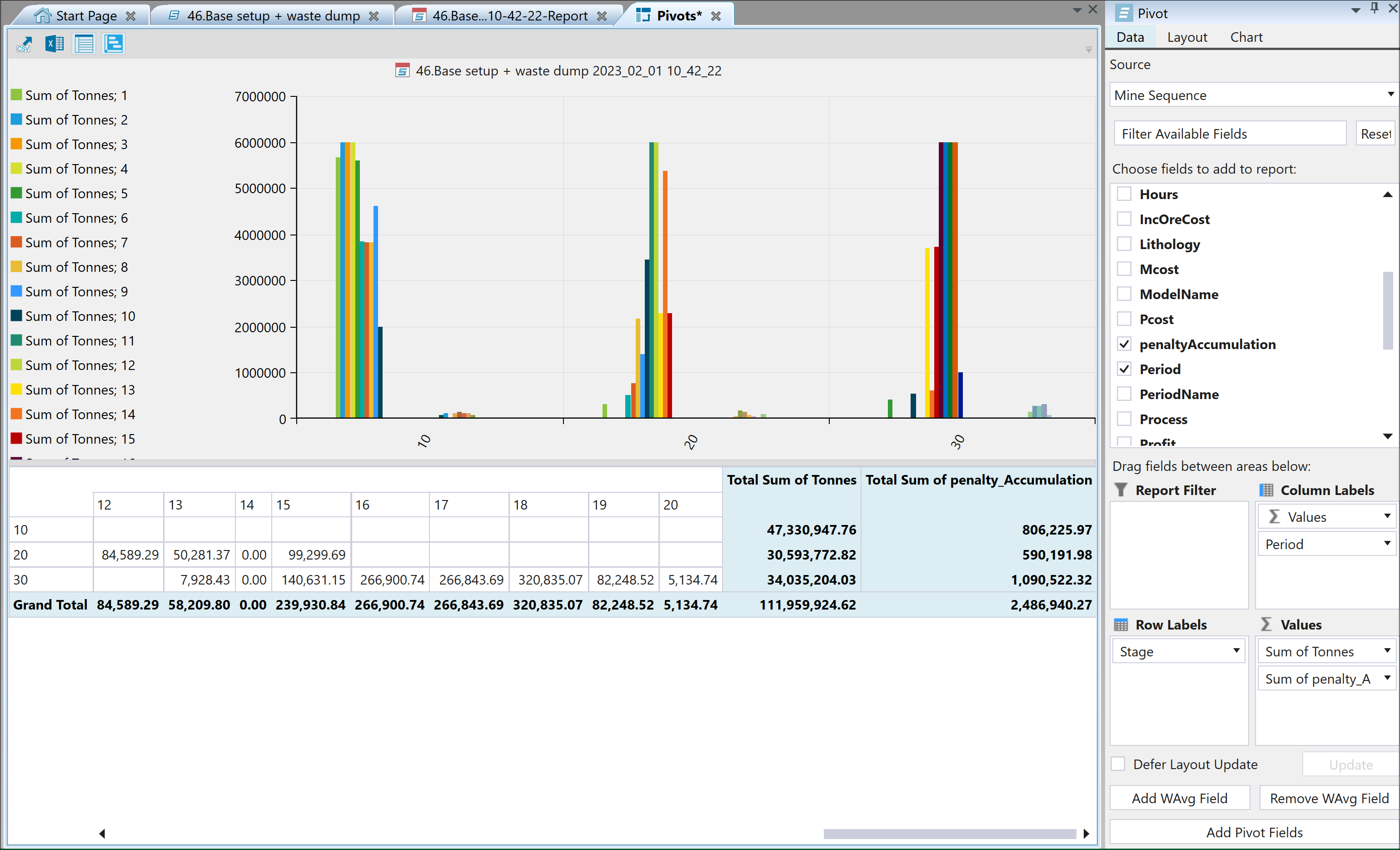

Any additional reporting items will be also reflected in the pivots (for more information, see Pivot Reporting).

The ![]() Fields subtab also allows you to specify custom names for each stage in the pits. These names will be reflected in the reports.

Fields subtab also allows you to specify custom names for each stage in the pits. These names will be reflected in the reports.