Objectives

Source file: origin-solids-setups-objectives.htm

Objectives in Origin Solid setups

The objectives guide the Evolution engine to derive the best outcomes in schedules for your setups. When you first create an Origin Solid setup, you must select one of the following primary objectives:

-

Material Movement: Use diggers to model the movement of material from all pit and stockpile sources to all mill and stockpile destinations. See Material Movement for more information.

Material Movement: Use diggers to model the movement of material from all pit and stockpile sources to all mill and stockpile destinations. See Material Movement for more information.Note: When generating schedules for Material Movement setups, Evolution does not take into account the time taken to transport material from the pit to other locations (for example, stockpile, mill, or waste utility).

Or

-

Equipment: Use diggers, trucks, and road networks to model the movement of material from all pit and stockpile sources to all mill, stockpile, and waste utility destinations. This includes modelling truck movement and available hours. Setups can be limited by truck hours when required. See Equipment for more information.

Equipment: Use diggers, trucks, and road networks to model the movement of material from all pit and stockpile sources to all mill, stockpile, and waste utility destinations. This includes modelling truck movement and available hours. Setups can be limited by truck hours when required. See Equipment for more information.

You can also set the following optional objectives:

-

Blend: Achieve blend targets through prioritising mining sequences that produce better blend outcomes by redirecting material that was bound for a stockpile directly to a process and, optionally, by redirecting material between processes. See Blend for more details.

Blend: Achieve blend targets through prioritising mining sequences that produce better blend outcomes by redirecting material that was bound for a stockpile directly to a process and, optionally, by redirecting material between processes. See Blend for more details. -

NPV: Perform value calculations during a schedule optimisation to generate higher values based on costs and revenue. See Net Present Value for more information.

Note: The

Min-Max objective is not available in Origin Solids.

Min-Max objective is not available in Origin Solids.See also: Create an Origin Solids Setup

These are soft objectives, which means that Evolution can violate them if it cannot find a solution that satisfies all of them at once.

If a target for digger hours cannot be met without missing the mill feed target, one of these requirements may be exceeded.

Note: In practice, if a population size is high enough (proportional to the number of schedules the engine explores), violations usually only occur when no valid alternative exists. Therefore, while objectives guide the Evolution engine, they are not strict limits like the selected period target is. For more information on population size settings, see Settings for Origin and Population Size.

This approach allows Evolution to agilely explore trade-offs and find practical, high-quality schedules, even when the setup constraints are tight.

Combining targets and objectives for the best schedule outcomes

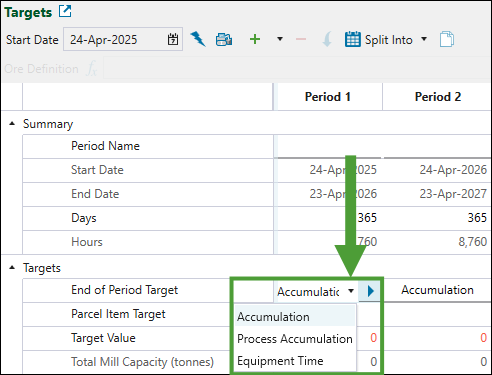

When configuring your Origin Solids setup, you must select one of the following End of Period Target types in the ![]() Targets subtab of the

Targets subtab of the ![]() Calendar tab:

Calendar tab:

-

Accumulation: Set the total amount of material to be moved in a given period.

Note: When you set Accumulation as your end of period target, you must also specify the Parcel Item Target (by selecting either Tonnage or Volume from the drop-down) and Target Value fields. For more information on parcels in Origin Solids, see Parcel Reporting.

-

Process Accumulation: Set the total amount of material to be fed to processing nodes (for example, mills) in a given period.

Note: When you set Process Accumulation as your end of period target, you must also specify the Parcel Item Target (by selecting either Tonnage or Volume from the drop-down). For more information on parcels in Origin Solids, see Parcel Reporting.

-

Equipment Time: Set the total operation time for your equipment in a given period.

See also: Targets

The target that you set becomes the hard constraint that defines when the period ends. Evolution will combine the two other targets that you have not selected into a single default objective based on which it will proceed with optimisation. In addition to these two remaining targets, Evolution includes the following factors when calculating the value for the default objective:

-

The number of actual truck hours used against the expected truck hours usage.

-

The number of actual digger hours used against the expected digger hours usage.

-

The actual mill feed against the target mill feed.

-

The amount of wasted ore (ore sent to waste instead of processing node).

-

The amount of rehandled ore (ore sent to overflow stockpiles instead of being processed directly).

Each of the above factors contributes to a total violation score that the engine minimises during optimisation. The value achieved for this default objective for the derived schedules allows you to compare them to one another and find the most optimal one. The closer a schedule meets these soft objectives, the lower the score.

The additional objectives that you set when you create a setup (maximizing the NPV or meeting a blend target) are treated independently from the default objective and are used alongside it when optimising multiple objectives.

Scheduling for multiple objectives

When multiple objectives are active, Evolution uses multi-objective Pareto ranking to evaluate trade-offs. That is, Evolution compares solutions based on how well they satisfy all objectives, without collapsing them into a single score or losing fidelity in any of the areas.

Instead of choosing just one best schedule, Evolution identifies a group of high-quality options, each representing a different balance across the objectives.

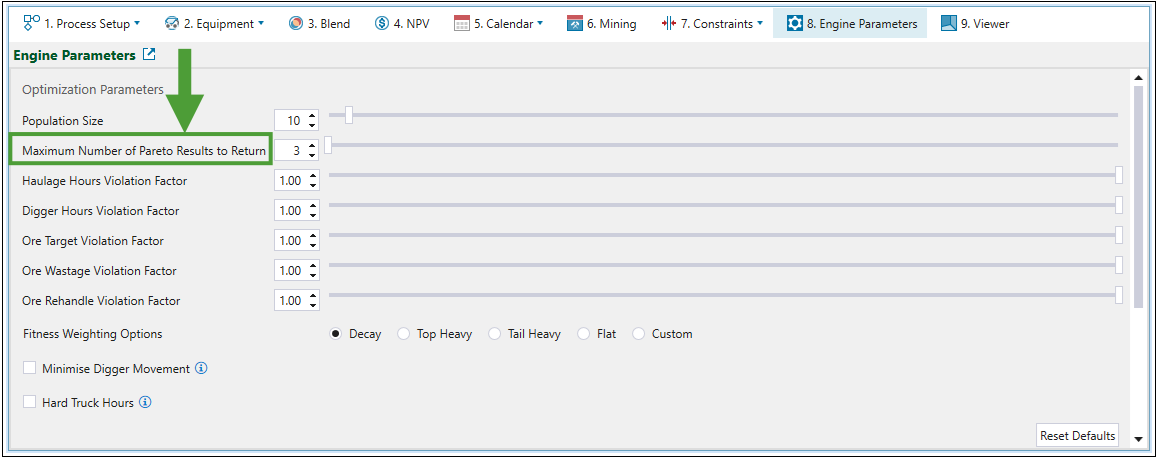

Note: To set the number of Pareto solutions that the Evolution will return for your review, apply the required setting in the ![]() Engine Parameters tab.

Engine Parameters tab.

See Engine Parameters for more information.

One of the possible solutions might slightly favour a higher NPV at the cost of exceeding a blend range, while another solution keeps the blend tight but produces slightly lower value. By presenting these trade-offs, Evolution gives you the flexibility to decide which outcome best suits your goals.