Specification

Set Up Block Reserves Specifications File

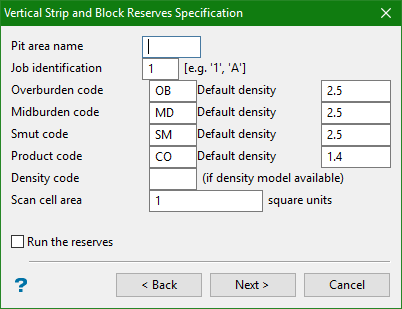

Use the Specification option to specify how the block reserves are to be calculated. The specifications are stored in a file named <proj><pit area name><job identifier>.st1. An example of a specification file is listed in Appendix A.

Once the specification file has been created, the Run Batvol option can be used to perform the calculations.

Instructions

On the Open Pit menu, point to Batvol, and then click Specification to display the Block Reserves Specification panel.

Pit area name

Enter the pit area name (up to 4 alphanumeric characters). The pit area name is first specified when selecting mining and strip advance directions through the Direction option (under the Benching and Batters submenu). It is used in the block reserves specification file name and in the reserve database name.

Job identification

Enter the job identification (single alphanumeric character only). This is also used in the block reserves specification file name.

Calculate reserves for blocks totally excluded by seam masks

Select this check box to calculate the reserves for all blocks, including those outside the mask, using the Run Batvol option. If the coal seam has a thickness outside the mask, then the volume will be reported as 100% smut. However, if you have many zero thickness seams, then these will also be reported in the database as zero volumes.

If this check box is not selected, then the reserves are only calculated for the blocks that are inside the seam mask. The volume of the coal (as denoted by the top and bottom seams) will be zero where the seam mask denotes the zero thickness of the coal. Therefore, there is no difference in volume.

Honour exclusion (anti-clockwise) masks

Select this check box to honour the seam exclusion masks (that is, anti-clockwise polygon masks) while reserving. If this check box is selected, then the anti-clockwise polygons in the mask strings will be treated as exclusion masks.

If this check box is not selected, then the clock-sense of each mask polygon is ignored, that is, each mask polygon will be treated as an inclusion masks.

Note: Exclusion masks are generally used to exclude areas that lie in inclusion masks. Coal that lies in an exclusion mask for a reserved block will be reported as "smut".

Overburden code

Enter the overburden code. This represents the overlying waste and associated density.

Midburden code

Enter the midburden code. This represents the waste between coal seams and associated density.

Smut code

Enter the smut code. This represents the non-coal constituents in a coal seam and the associated density.

Product code

Enter the project code. This represents the coal you are interested in and the associated density.

Density code

Enter the grid model of density.

Scan cell area

Enter the scan cell area (the default value is 1). This is the size of the cell which is used to sub-sample quality grids. Using a smaller value may take longer, as more sub-sampling of the grid is carried out.

The algorithm uses bilinear interpolation to estimate values at the centre of the sub-cells, from existing grid node values. This algorithm is used regardless of the modelling method used to interpolate the grid node values originally. The distance between sub-sampling points is the square root of the scan cell area.

Use tie lines

Select this check box to guide the triangulation. A line can be built between two strings that you want to triangulate. These lines form a predetermined layer and are digitised using all the normal spatial functions.

If this check box is not selected, the system will generate what it calculates as the best triangles to use between two strings. If the generated triangles are not suitable, then you can add tie strings using interactive ties to constrain the model. Refer to the Model > Triangle Solid > Create option for further details on tie strings.

Run the reserves

Select this check box to immediately run the reserves upon completion of the Specification panels. If this check box is not selected, only the specification file will be generated. The

Run Batvol

option can then be used to run, or rerun the reserve calculation.

Note: Save the projected blocks before running reserves.

Click Next.

The following panel displays.

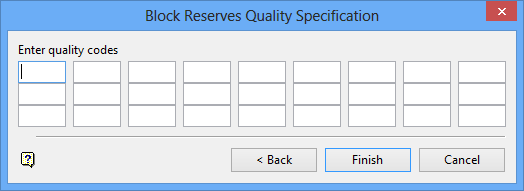

Block reserves quality specification panel

This panel to specify quality codes. Quality codes are analytical values for coal, such as ash, sulphur, grindability, etc. They are normally modelled as grids and then mass weighted for the block and reported.

Click OK.

The Multiple Selection box displays. This to select the blocks by category. Cancel when finished selecting objects.

The blocks will then be included in the reserves specifications file.