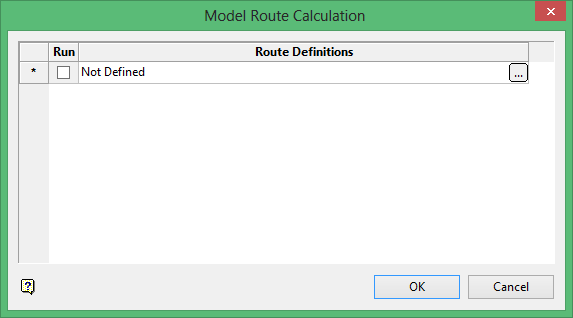

Model Route Calculation

Use Model Route Calculation to store productivity results, cycle time and round trip distances to block model variables.

Prerequisites

- Block model variables must be added to the block model prior to running this option. Refer to the Block > Manipulation > Add Variable option for more information on adding block model variables.

- The chosen block model needs to contain variables that define ore, waste or other. Other materials can be defined as anything other than ore and waste, that is, high grade, low grade, stockpile material, etc.

Click

![]() Route Calculation button from the Haulage toolbar.

Route Calculation button from the Haulage toolbar.

Tutorials

Click to view related tutorials.

Instructions

On the Open Pit menu, point to Haulage Profile, and then click Model Route Calculation to display the Model Route Calculation panel.

Use this panel to create, adjust and execute route definitions. These specifications are saved in the

haulage_route_profile.spc

. This file will be stored in your current working directory.

Run

Select this check box to execute a defined route definition.

Route definitions

This column lists all existing route definitions.

To create or adjust a route definition, select the

button. Once selected, the Route Definition panel displays.

button. Once selected, the Route Definition panel displays.

Click OK to save the specifications to the

haulage_route_profile.spc

file. If you have chosen to execute a specific route definition, then you will be required to select the route.

Vulcan will check the truck library for a version number. If this number does not match the latest version, you will be prompted to run validation.

The Route Definition panel will display.

This panel is divided into six different tabs:

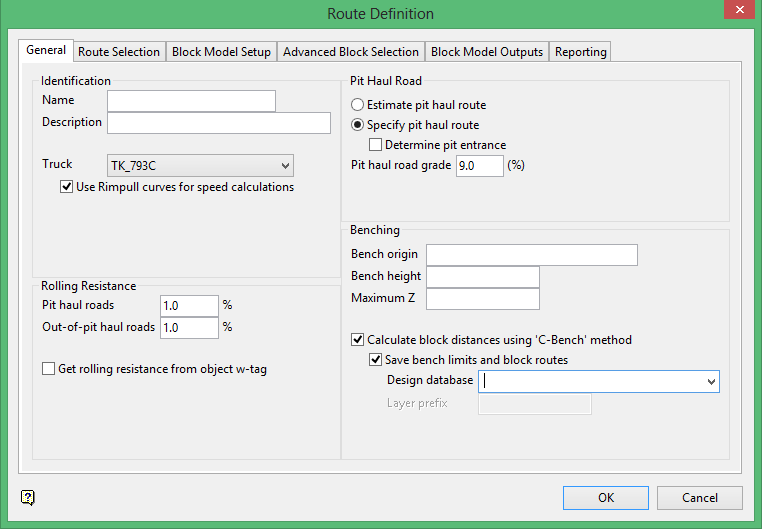

General

Identification

Name

Enter the name of the estimation route.

Description

Enter a description for the estimation route.

Truck

Select from the drop-down list the name of the truck that will be used in the estimation.

The drop-down list displays all of the trucks that are contained in the

haulage_truck_library.spc

file. If the drop-down list does not contain any trucks, then you will need to define them using the

Truck Library

option.

To use Rimpull values in speed calculations instead of standard speed curves, select Use Rimpull curves for speed calculations. For more information on Rimpull curves, see the Rimpull tab .

Pit Haul Road

Estimate pit haul route

This calculation will be used when you do not specify a string going up on the existing haul road to the entrance/exit of the pit.

Specify pit haul route

This calculation will be used when you do specify a string going up on the existing haul road to the entrance/exit of the pit.

Determine pit entrance

We recommend that you check this check box if you have a pit where the exit is lower than the top benches and the pit string goes above the exit point. If this check box is not checked, then all trucks going downhill from the highest bench to the pit exit will be calculated using uphill loaded instead of downhill loaded.

Pit haul road grade

The grade which will be used to estimate the haul from the entrance/exit of the pit if a pit haul has not been defined.

Rolling Resistance

Describes the resistance on the truck due to friction.

Pit haul roads

Enter the rolling resistance value for roads inside the pit.

Out-of-pit haul roads

Enter the rolling resistance value for roads outside the pit.

Get rolling resistance from object w-tag

Set the rolling resistance values to populated from the block model w-tag.

Benching

Bench origin

Enter a value for the bench origin. This value, which is usually the toe elevation of one of the pit benches, defines the minimum bench elevation for the calculation, or where the calculation will start. Bench elevations lower than the specified value will not be included in the calculation.

Bench height

Enter the bench height. This value defines the height of the open pit bench.

Maximum Z

Enter the maximum Z level. This value, which is usually the crest elevation of one of the pit benches, defines the maximum bench elevation for the calculation, or where the calculation will stop. Bench elevations greater than the specified value will not be included in the calculation.

Calculate block distances using 'C-Bench' method

When measuring the shortest distance between two points on a bench, such as from the block to be mined to the bench entrance, measurements become unrealistic when the two points are at either ends of a C-shaped bench, and the shortest path between these points crosses mid-air. To solve this problem, the C-bench method determines the route distance by following the shape of the bench on which route is located.

This option is enabled only if a bounding triangulation has been specified in the Advanced Block Selection tab.

Save bench limits and block routes

This option lets you save the results of operations using the C-bench method to the specified Design database and layer prefix.

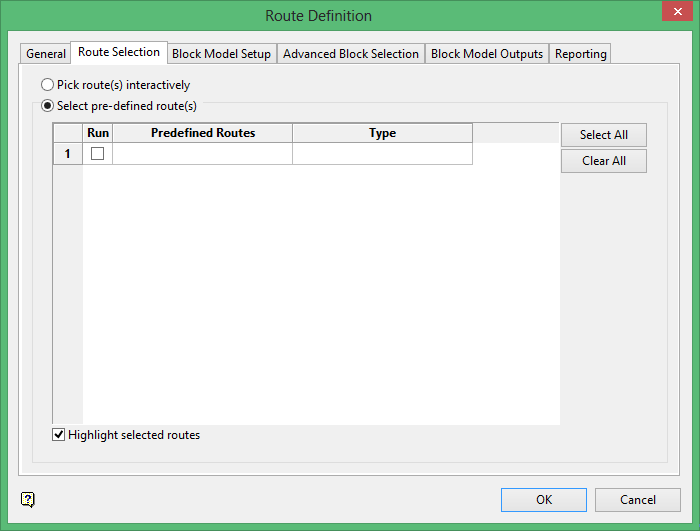

Route Selection

Pick route(s) interactively

If you select this option and click OK you will be prompted to pick polygons from the screen to use as routes.

Select pre-defined route(s)

Select this option to access a list of routes previously set up in Build Haulage Route Network > Create Haulage Route.

Run

Selecting one or more predefined routes and clicking OK executes a run that is already set up.

Predefined Routes

Lists routes predefined in Build Haulage Route Network > Create Haulage Route.

Type

Describes the type of material and its destination specified in Build Haulage Route Network > Create Haulage Route. Types are either Crusher (Ore), Dump (Waste) or Stockpile (Other).

Highlight selected routes

Selected routes are highlighted.

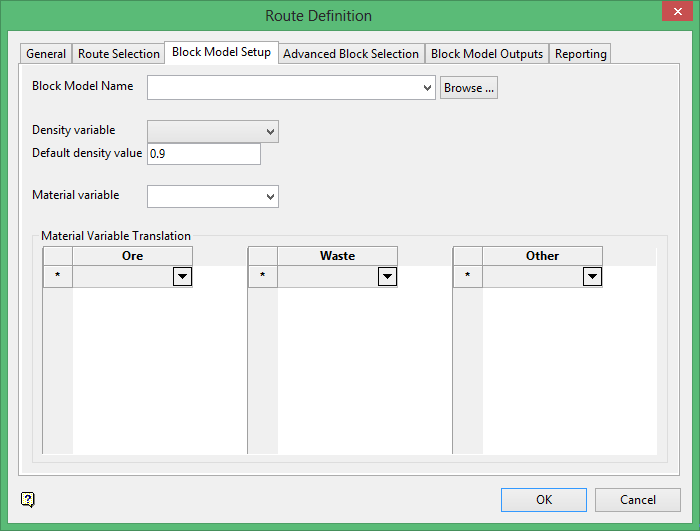

Block Model Setup

Use this section to load a block model representing the material to be transported.

To effectively use this panel, it is recommended that you load a block model which uses numerical identifiers to reference ore, waste or other material types.

Block Model Name

Browse for, select from the drop-down list, or enter the name of the block model for which you are calculating route definitions.

Density Variable

If this field is not automatically populated from the selected block model, then select a variable from the drop-down list to represent the density of the material to be transported.

Default density value

Select the default density of the material to be transported. If no density variable is selected, the default density is set to 0.9.

Material variable

The material variable is a numerical code which represents the type of material to be transported. This field should be automatically populated from the selected block model. The value refers to the numerical code assigned by the user to values in the Material Value Translation categories..

Material Variable Translation

Users should assign a numerical code to sub-types in the Ore, Waste, or Other categories. This code maps the Material variable to one of these sub-types. Each numerical code should be unique.

The Ore category could contain three subtypes which each reference an ore grade. Each ore grade is assigned a unique numerical value (For example,, 1,2,3), which differ from values assigned to sub-types in Waste or Other categories.

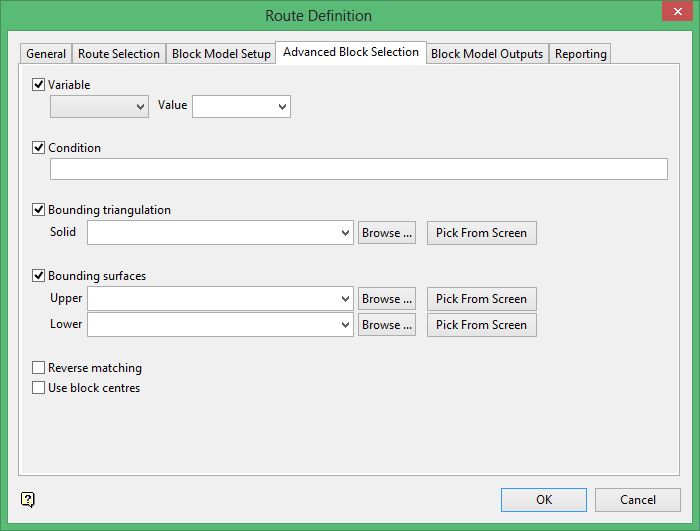

Advanced Block Selection

Use this section to further define the block model to be transported.

Use this section to specify the block selection methods that are to be used.

The bounding triangulation and surfaces are for selection only, that is, it does NOT take proportional values such as productivity, distance and cycle time. You will also need to create the limit polygon for the option to work.

Variable

Select this check box to restrict the blocks by a specific block model variable and value. You will need to select the variable, as well as specify a particular value. The block model variable may be numeric (For example,, the grade variable

Au

) or character (For example,

Geology

) variables.

To restrict blocks to those where

Material

equals

Ore

, select

Material

as the variable from the drop-down list and enter

Ore

as the value. However, if you require all blocks that

do not

have this specified value, then enable (check) the Reverse matching check box.

Condition

Select this check box to apply further constraints to a numeric block model variable, For example,

Fe GT 10.0

(iron value greater than 10.0). The maximum size of the condition is 132 alphanumeric characters. A list of available operators/functions is provided in Appendix D.

Bounding triangulation

Select this check box to restrict the blocks by a triangulation. This is useful when, for example, you want to evaluate reserves in a particular solid triangulation, such as a stope.

The necessary surface can either be selected from the screen, the drop-down list or through browsing your available data directories. This option is not applicable to open or 2D triangulations.

Bounding surfaces

Select this check box to restrict the blocks by bounding surfaces. The necessary surfaces (both upper and lower) can either be selected from the screen, the drop-down lists or through browsing your available data directories. Only blocks that lie in the overlapping sections of the surfaces (as viewed in Plan view) are selected.

Reverse matching

Select this check box to reverse the constraints specified through the Variable option.

Use block centres

Select this check box to use the full cell evaluation method. If this check box is not selected, then the proportional cell evaluation method will be used instead.

- Full cell evaluation: Include blocks if the block centroid is in the region. The entire block will be included.

- Proportional cell evaluation: Include those blocks that touch the region, and evaluate reserves according to the proportion of the block's volume that lies in the region. Proportional cell evaluation calculates and reports the exact proportion of a block in a solid triangulation. When selecting blocks, all blocks that touch the region are selected.

Click OK to return to the Model Route Calculation panel.

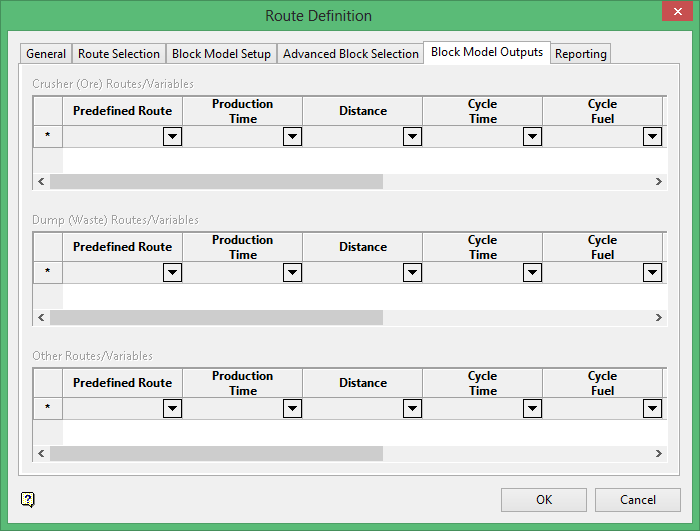

Block Model Outputs

The Block Model Outputs panel calculates haulage variables for a selected route and material type. Haulage variables for different routes may be calculated to support selection of the most efficient route.

Crusher (Ore) Routes/Variables, Dump (Waste) Routes/Variables, and Other Routes/Variables

The category to be configured in this panel depends on whether the Material code set in Block Model Setup references a type of Ore, Waste or Other material. If one of the Ore, Waste, Other categories in the Block Model Setup panel does not have a material variable configured, then the corresponding Routes/Variables section in this panel will be unavailable.

In the available Routes/Variables section on this panel, in the Predefined Route column, select one of the routes defined in the Route Selection panel.

In the remaining columns, select the appropriate block model variable from the drop-down list. You may also create a block model variable on the fly by entering its name in the drop-down list. On-the-fly variable creation is not available for Equivalent Mass-Distance and Equivalent Distance values.

Creating a block model variables on the fly will only work when using extended models .

Predefined Route

Select one of the routes defined in the Route Selection panel.

Production time

Select the variable that stores how many minutes it will take for one truck to mine a single block model block.

Distance

Select the variable that stores the trip distance from the loader to the material destination.

Cycle time

Select the variable that identifies the Cycle time. Cycle (time/distance/fuel) time is defined as the time it takes for a truck to be loaded and travel along a specific route from the block pit to the material destination (crusher, dump, other), remove its load, and return to the block pit, empty. Any expected delays are added to this travel time.

Cycle fuel

Select the variable that stores the truck's round-trip fuel consumption.

Fuel per hour

Select the variable that stores the truck's fuel consumption per hour.

Fuel per ton

Select the variable that stores the amount of fuel consumed per ton of ore mined.

Equivalent Mass-Distance

This option is available if the setting has been selected in the Truck Library > Specification panel.

Equivalent Distance

This option is available if the setting has been selected in the Truck Library > Specification panel.

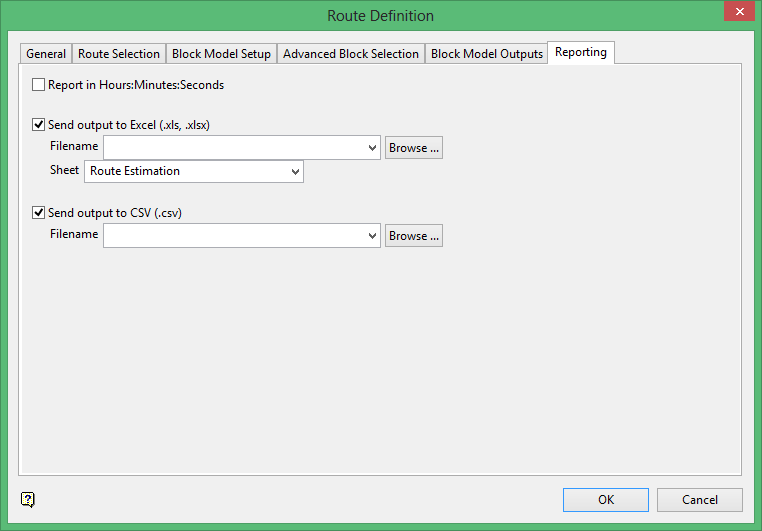

Reporting

Use this panel to configure how to report the results of Route Definition calculations. The report essentially shows the average time for a truck to transport a block on a route from a bench.

Report in Hours:Minutes:Seconds

Select this check box to report the times in hours, minutes and seconds (HH:MM:SS).

Send output to Excel (.xls)

Select this check box to send the report to an Excel spreadsheet. To create a new file, enter the file name and file extension.

To send the resulting report to a new worksheet in an existing spreadsheet, specify the name of the spreadsheet. The drop-down list displays all of the Excel spreadsheets found in your current working directory. Click Browse to select a file from another location.

Ensure that the Microsoft Excel application is not running when sending the report to an existing spreadsheet.

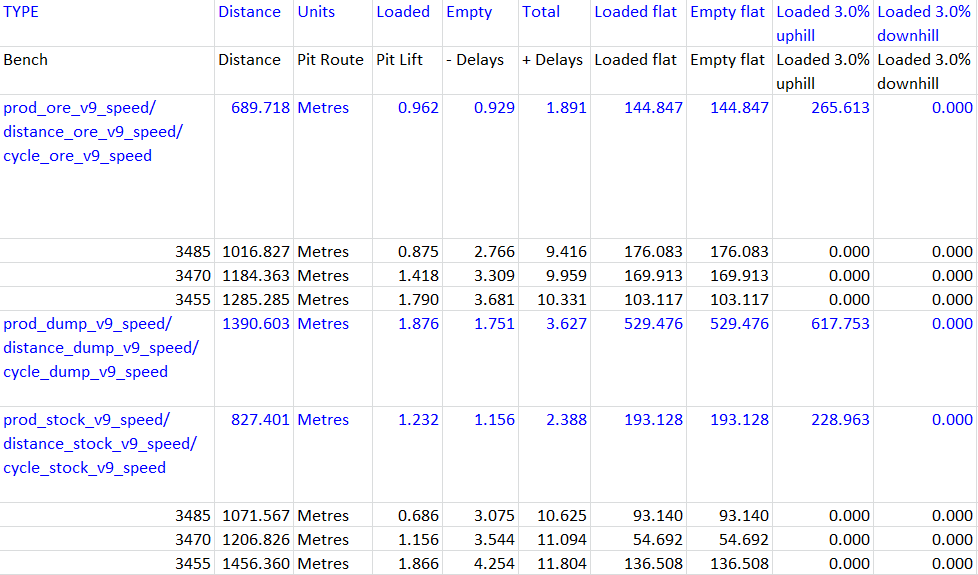

A report similar to that below is created, indicating speeds and distances for different routes and load conditions.

Excel Report example (truncated)

Send output to CSV (.csv)

Select this check box to send the report to a CSV file. To create a new file, enter the file name and file extension.

To send the resulting report to an existing CSV file, specify the name of the file. The drop-down list displays all of the CSV files found in the current working directory. Click Browse to select a file from another location. Selecting an existing file will result in the values in the chosen file being overwritten. As a result, you will be asked to confirm this selection upon completing this panel.

In a Model Route Calculation report, pit lift refers to the vertical distance to the surface. In the Loaded 3.0% uphill column and other similar columns, the percentage refers to the Grade Cutoff or equivalent Rimpull Cutoff described in Truck Definition > Performance.