Constraints

Source file: origin-reserve-setups-constraints.htm

Constraints provide you with advanced ways to refine data.

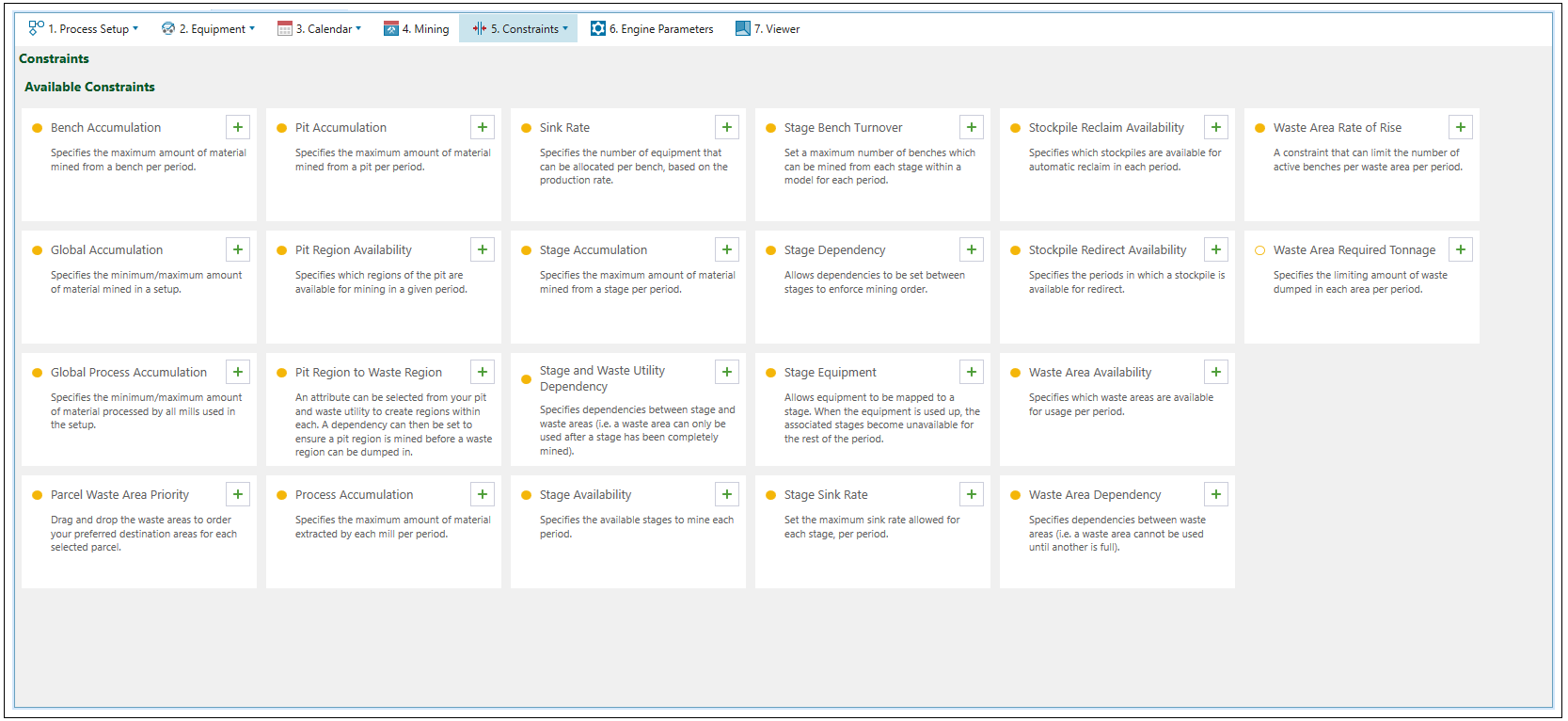

Click ![]() Constraints > Overview on the setup configuration tab to view the constraints available for your setup. Each constraint tile includes a short description.

Constraints > Overview on the setup configuration tab to view the constraints available for your setup. Each constraint tile includes a short description.

You can apply required constraints by clicking ![]() (Add new constraint). The constraints applied to your setup will appear on the left side of your screen, as well as under the

(Add new constraint). The constraints applied to your setup will appear on the left side of your screen, as well as under the ![]() Constraints configuration drop-down.

Constraints configuration drop-down.

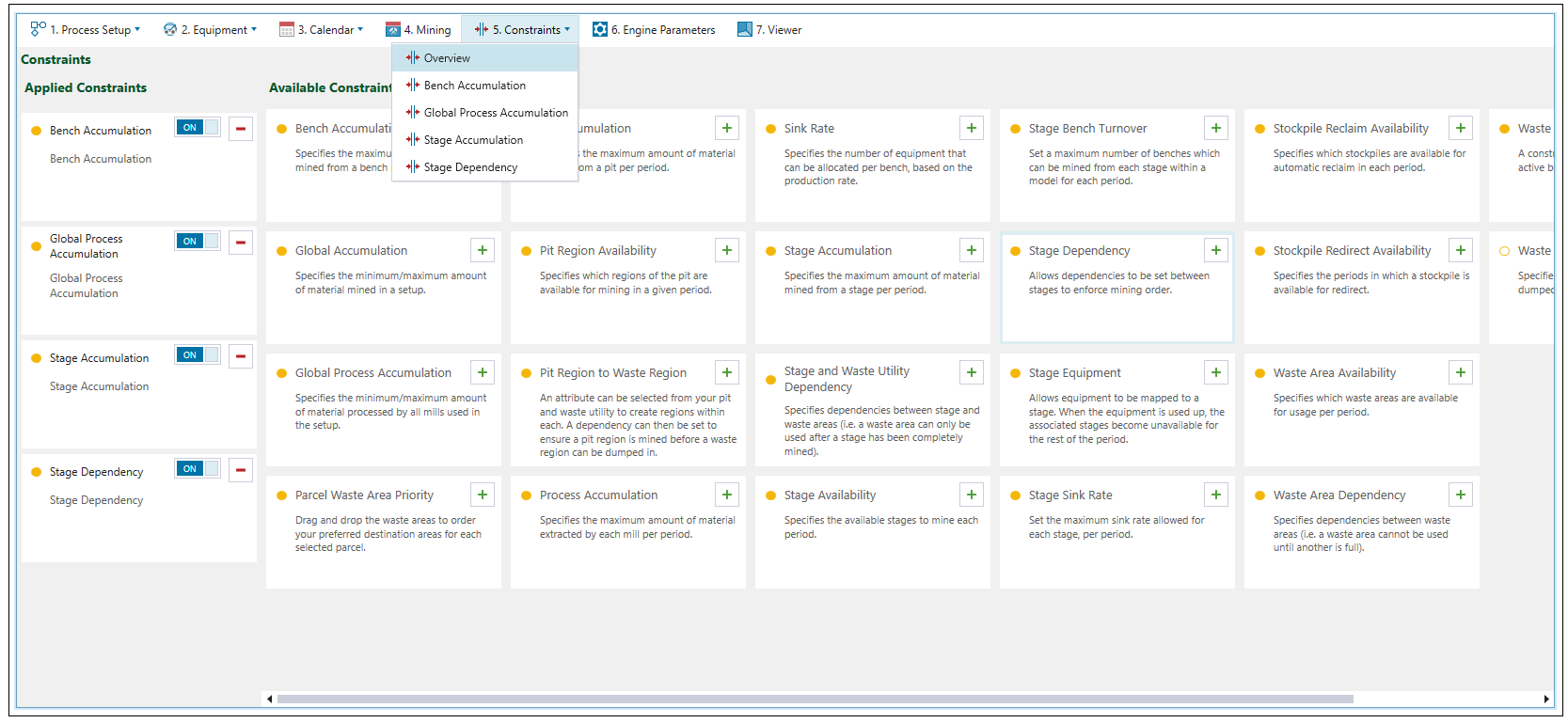

Constraint detailed setting screen can be entered by:

-

Clicking on the required constraint on the Applied Constraints list.

-

Selecting the required constraint from the

Constraints configuration tab.

Constraints configuration tab.

The following buttons appear on all constraints to provide unified and simplified ways of operation:

|

|

Add new constraint

|

|

| |

Enable or disable constraint

|

|

|

|

Delete constraint

|

|

|

|

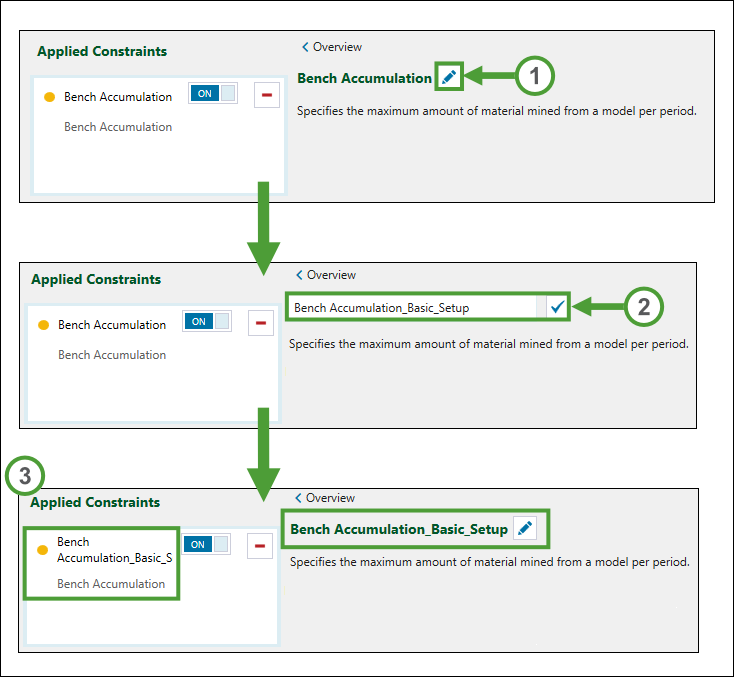

Edit constraint name To rename a constraint do the following:

|

|

|

|

Clear the selected cell

|

|

|

|

Overview

|

|

The following table provides a description of each constraint available in Origin Solid setups. Constraints are classified as hard (![]() ), which must be obeyed by the software when it determines a schedule, or soft (

), which must be obeyed by the software when it determines a schedule, or soft (![]() ), which the software aspires to meet but is not obliged to).

), which the software aspires to meet but is not obliged to).

| Constraint | Hard (H) / Soft (S) | Description |

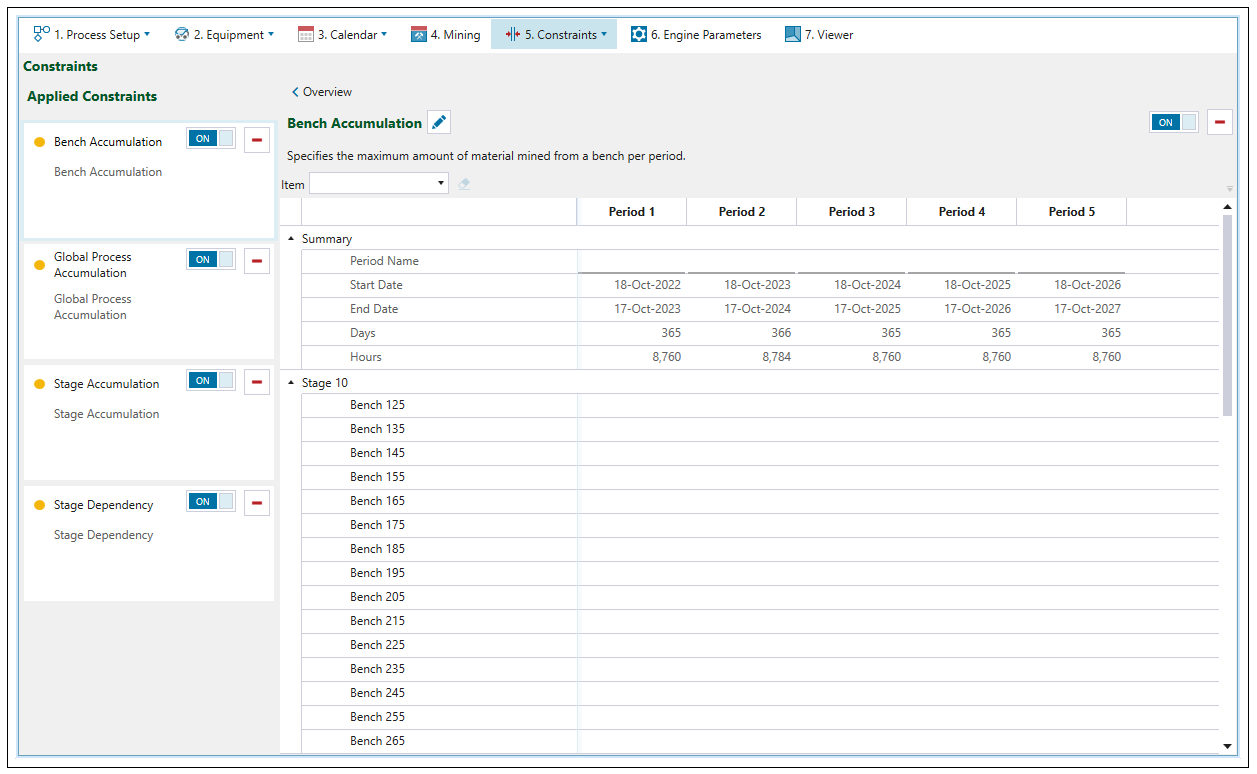

| Bench Accumulation | H | Used to set the maximum amount that can be mined per bench per period. |

| Global Accumulation | H (for maximum), S (for minimum) |

Used to set a maximum/minimum volume or amount of tonnes that can be mined per period. |

| Global Process Accumulation |

H (for maximum), |

Used to set a maximum/minimum accumulation that is moved from any pit, to any mill in a setup per period. |

| Pit Accumulation | H (approximate) | Used to define the maximum volume or amount of tonnes that can be mined per pit per period. |

| Parcel Waste Destination Priority | H | Used to set a priority order of waste areas for each parcel in the setup. |

| Pit Region Availability | H | Used to set the mining availability of areas in each period. Typical regions used include bench or stage. |

| Pit Region to Waste Region | H | Used to map regions in the pit to regions in the waste utility. |

| Process Accumulation | H | Used to restrict the maximum amount of material a mill can process per period (tonnage or volume). |

| Sink Rate | H (approximate) | Used to calculate the mining duration per bench, based on the total tonnes available for mining on a bench and the corresponding dig rate. |

| Stage Accumulation | H (approximate) | Used to restrict the amount of material (tonnage or volume) that is mined per stage in a pit per period. |

| Stage and Waste Utility Dependency | H | Used to assign dependencies between the stages and waste areas. |

| Stage Availability | H | Used to flag the availability of stages for mining per period. |

| Stage Bench Turnover | H | Used to set the maximum number of benches that can be mined in each stage per period. |

| Stage Dependency | H | Used to define the mining order of stages. |

| Stage Equipment | H | Used to map equipment to specific stages in a pit. |

| Stage Sink Rate | H (approximate) | Used to set the maximum sink rate allowed for each stage in each period. |

| Stockpile Reclaim Availability | H | Used to set the period in which the material can be reclaimed from a stockpile. |

| Stockpile Redirect Availability | H | Used to specify the periods in which the stockpile material can be redirected to a mill. |

| Waste Area Availability | H | Used to set the availability of each waste area for waste dumping on a periodic basis. |

| Waste Area Dependency | H | Used to specify dependencies (usage order) between waste areas. |

| Waste Area Rate of Rise | H | Used to limit the number of active benches per waste area in each period. |

| Waste Area Required Tonnage | S | Used to set the maximum amount of waste that can be dumped per area in a period. |

Approximate constraints

The Evolution engine determines the sequence of solids to be mined (for example, A, then B, then C). No solid constituting this sequence can be split and interspersed among other mined solids. For example, if separating solid A was inevitable, it would still need to be mined sequentially (A (part 1), then A (part 2), then B, then C), and interspersing it among other solids (A (part 1), then B, then A (part 2), then C etc.) would not be possible.

Consequently, in order to meet the period targets and maintain a single mining sequence, the solid should be split at the end of a period. This split criterion affects the constraints that limit the amount of material taken from the pit.

For example, if Stage Accumulation constraint sets the stage A mining limit in period 1 to 1000 tonnes, but a solid weighing 1500 tonnes was mined in that stage, then the exceeding value would be recorded and the mining from that stage would be stopped.

It is recommended that models be composed of multiple small solids. This will help the constraint limit be achieved more closely, as an approximate hard constraint can only ever be exceeded by a portion of one solid.

.