Capital Layout

Source file: strategy-setups-economic-model-capital-layout.htm

The ![]() Capital Layout subtab under the

Capital Layout subtab under the ![]() Targets & Economics tab allows you to specify the mining scenarios that involve increasing the processing capacity. On this basis, Strategy can evaluate if the capacity should be increased and when, which excludes human error and the time required for testing and trials. If a schedule with a higher NPV (net present value) result is generated, Strategy will be able to decide on proceeding with the expansions. Consequently, the increase in related capital and operating costs will be applied to the periods for which Strategy has allowed for the expansions to be made.

Targets & Economics tab allows you to specify the mining scenarios that involve increasing the processing capacity. On this basis, Strategy can evaluate if the capacity should be increased and when, which excludes human error and the time required for testing and trials. If a schedule with a higher NPV (net present value) result is generated, Strategy will be able to decide on proceeding with the expansions. Consequently, the increase in related capital and operating costs will be applied to the periods for which Strategy has allowed for the expansions to be made.

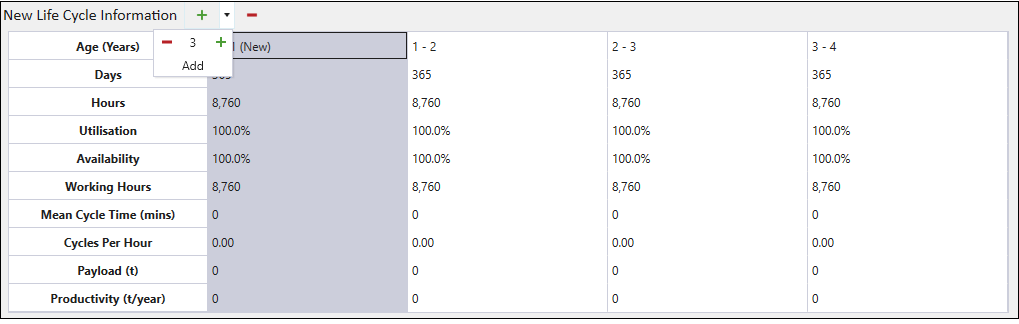

Fleet Config

The Fleet Config tab provides an interface to define the cost to buy and refurbish a truck fleet. Performance information can also be provided throughout the lifetime of the fleet.

For each fleet, the following information is required:

-

Fleet Information: Specify the name of the fleet in the Resource Name field.

-

Existing fleet: Specify the number and the age of the existing fleet in the Count and Age (Years) fields.

-

Replacement options: Specify the maximum number of trucks that can be considered in the Upper Limit field, and the capital expenditure associated with a brand new fleet in the Replacement Cost field.

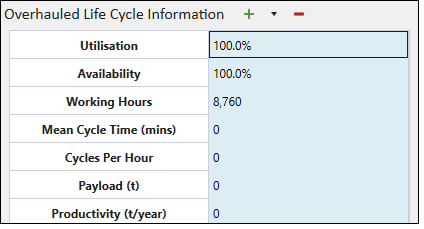

Note: The Can be Rebuilt (Overhauled) checkbox signifies that the unit can be rebuilt instead of being completely replaced. When you select this checkbox, a new field called Overhaul Cost and a new section called Overhauled Life Cycle Information to be filled out will appear.

A secondary section called New Life Cycle Information has to be completed if the fleet is over a year old.

When you provide the lifecycle information for a new and overhauled fleet, Evolution calculates a number of derived parameters. These parameters are listed in the below table.

| Parameter | Definition |

| Utilisation (%) | The percentage of hours the fleet is used. |

| Availability (%) | The percentage of hours the fleet is available to be used. |

| Working hours |

Working hours are calculated according to the following equation:

|

| Mean Cycle Time (mins) | The mean cycle time is the parameter which you input manually. It is used to calculate the number of cycles per hour. |

| Cycles Per Hour |

The number of cycles per hour is calculated according to the following equation:

|

| Payload (t) | The amount of weight (expressed in tonnes) that a truck can carry. |

| Productivity (t/year) |

The productivity is calculated in tonnes on annual basis according to the following equation:

|

To add an older fleet, click ![]() and select the number of columns to be added. Each subsequent column will correspond to the successive age bracket.

and select the number of columns to be added. Each subsequent column will correspond to the successive age bracket.

Tip: You can edit the Days row to mark the gap year.

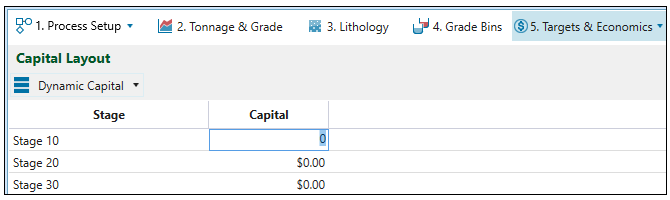

Dynamic Capital

The Dynamic Capital tab is used to assign a capital cost to each stage per pit. More expensive stages are scheduled to be mined later, while stages that are cheaper to mine are scheduled earlier in a mining sequence.

To enter the dynamic capital for each stage, double-click the field in the Capital column and enter the required value.

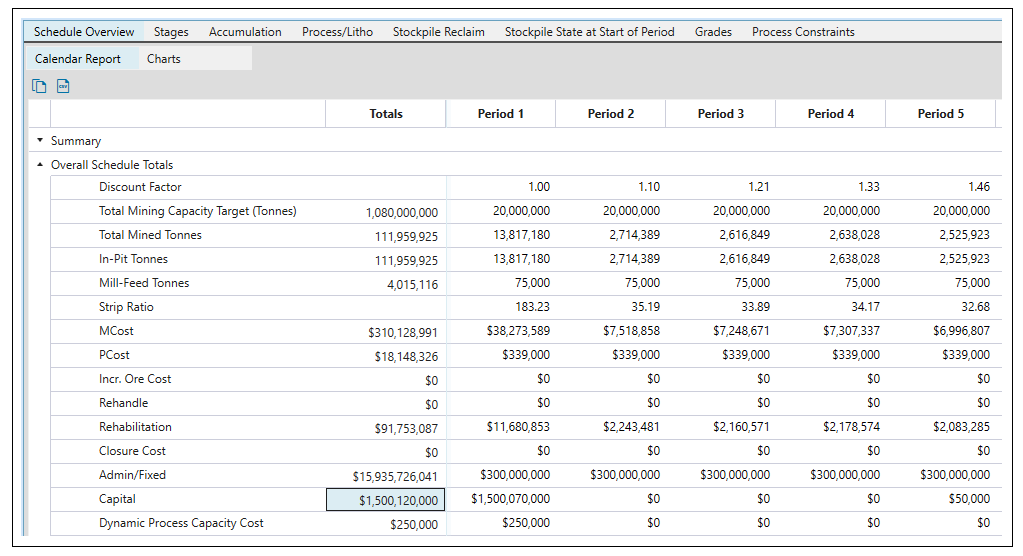

Capital calculation

The capital for a specific period in your schedule is calculated based on the dynamic capital and the capital injection, which is set in the Calendar subtab nested under the ![]() Targets & Economics. For more information on the capital injection, see Capital Injection.

Targets & Economics. For more information on the capital injection, see Capital Injection.

The formula used for capital calculation is as follows:

The results of these calculations will be applied to each period in your generated schedule.

For more information on generating schedules, see 4. Generate a Schedule.

Dynamic Process Capacity

The Dynamic Process Capacity tab is used to define several capacities per process and assign each an incremental cost for upgrading. When multiple capacities are provided, Evolution will make the optimum decision from the table and ignore the capacity set in the ![]() Targets & Economics >

Targets & Economics > ![]() Calendar. If only one capacity is defined, it will be ignored, and the value set in the

Calendar. If only one capacity is defined, it will be ignored, and the value set in the ![]() Targets & Economics >

Targets & Economics > ![]() Calendar will be used.

Calendar will be used.

You can specify the dynamic process capacity for each process node of your setup.

-

Click

to add a capacity to the table.

to add a capacity to the table. -

To remove a capacity from the table, click

.

. -

To align the capacities listed in the table in ascending order, click Sort.

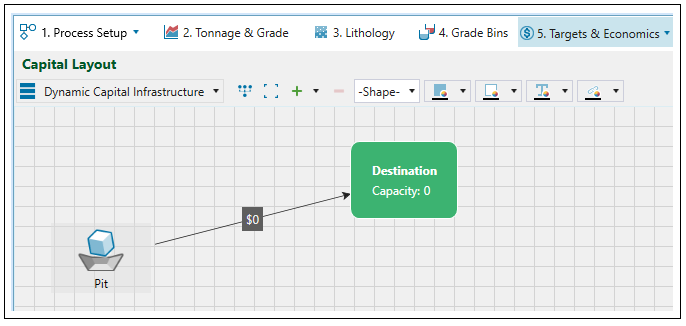

Dynamic Capital Infrastructure

The Dynamic Capital Infrastructure tab is an interface for defining storage destinations and the transportation cost of material.

When you define a few different paths, Evolution will select the optimal one.

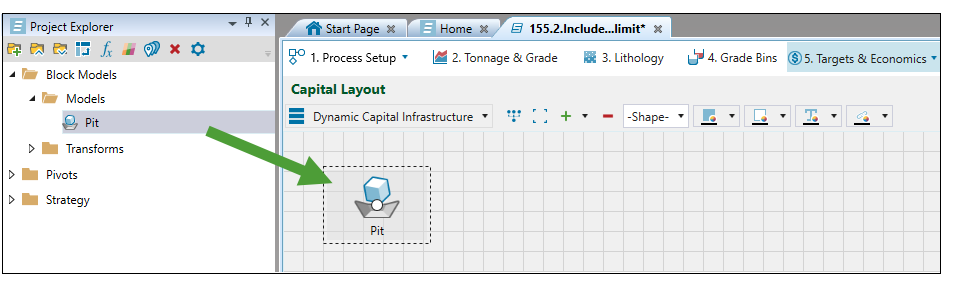

Follow these steps to specify the storage destinations and the cost of material for your setup:

-

Drag the model of your pit to the viewer.

-

Click

to add a destination.

to add a destination. -

Connect the pit to the destination. For detailed information on connecting setup components, see Linking process nodes.

-

Specify the transportation cost of material by double-clicking on the $0 field on the linking arrow.

-

Specify the capacity by double-clicking on the Destination field.

Tip: When you double-click on the Destination field, you can also change the name of your destination.

Tip: You can also customise the way the destinations are displayed in your viewer by using the toolbar. For more information, see the Material Flow toolbar.