Material Flow

Source file: epoch-setups-flowchart-flowchart.htm

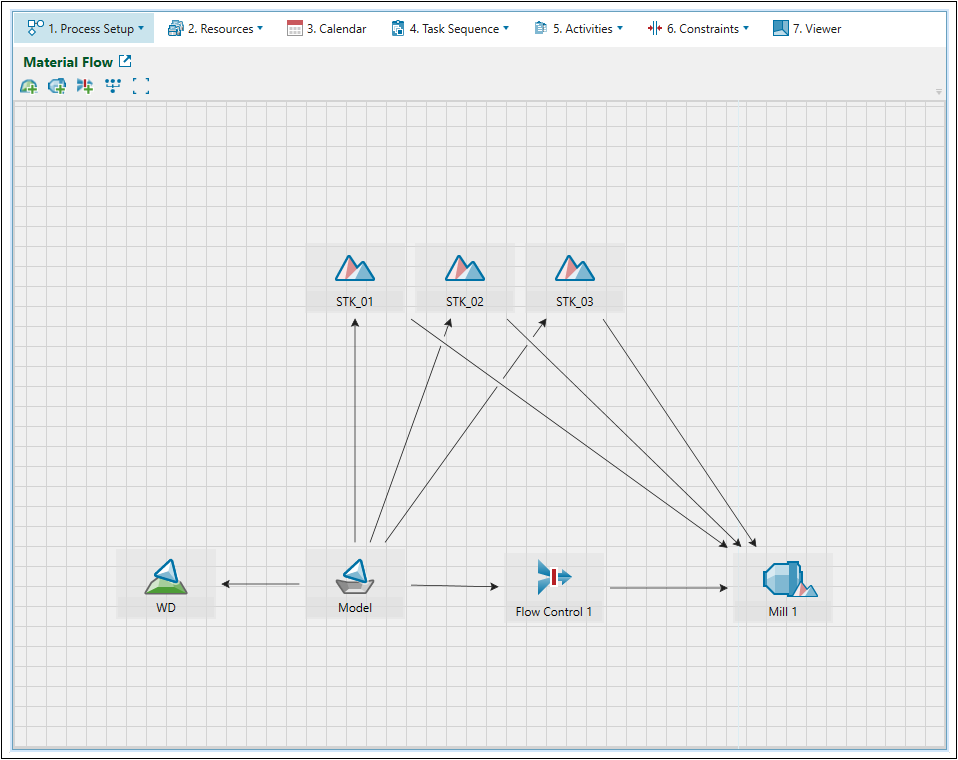

The ![]() Material Flow tab is used to define the flow of material within a setup by adding process components and linking them together.

Material Flow tab is used to define the flow of material within a setup by adding process components and linking them together.

Below is a list of process components that can be added to an Epoch setup. Components are categorised as either virtual or imported.

| Icon | Label | Type | Description |

|

|

Waste dump | Virtual | A waste dump is used to store waste material sent from a pit. |

|

|

Mill | Virtual | A mill processes material sent from a pit. Generally, an overflow stockpile is situated adjacent to it for the easy storage of low grade material. |

|

|

Flow control node | Virtual | A flow control node mimics the behaviour of a shaft in a mine. It is used to limit the amount of material transferred between a pit and a destination. |

|

|

Pit | Imported |

A pit represents a mining site. In Epoch setups, you can use solid pits (that are made up of irregularly shaped units described as solids) or dynamic solids pits (that are combinations of solid models and block models). See also: Solid Models, Dynamic Solids Pits, and Importing a Dynamic Solids Pit |

|

|

Waste utility | Imported | A waste utility is used to store waste material sent from a pit. It contains geometrical information that helps you to pinpoint where material is sent. |

|

|

Stockpile | Imported | A stockpile is a temporary storage site for low grade material. Later on in the schedule, material is sent from a stockpile to the mill to achieve end-of-period targets. |

Once components have been added, the flow of material can be defined by linking them together. To create a link between component A and B, complete the following steps:

-

Click on component A. A white circle with a black outline will appear in the middle of the component.

-

Click on the circle in the middle of component A an drag the arrow all the way to the black circle on component B and wait until the circle has a grey outline.

-

Release the mouse. The link should be created.