Stage Lag

Use the Stage Lag constraint to configure the minimum and maximum bench lag between the stages, which will help you to control the vertical and horizontal mining progression of the pit. Therefore, this constraint can help you to simulate scenarios where the pit would be mined out more horizontally or with a bench lag between a leading stage in comparison to another. Adding hard lag constraints between stages in a more automated way can speed up your workflow, resulting in running scenarios quickly to test different mining sequencing configurations, which will lead to finding better solutions quicker.

The Stage Lag constraint is similar to the Stage Bench Turnover and Stage Dependency constraints, with the following distinction:

-

The Stage Bench Turnover constraint determines the maximum number of benches that can be mined per stage in each period, not between the stages.

-

The Stage Dependency constraint defines the stage release strategy and precedence order in which the pit stages are available.

See also: Constraints in Strategy, Stage Bench Turnover, and Stage Dependency

To configure the constraint, you must first link two pit stages to create a dependency between them.

Note: Not all stages need to have a link.

Follow these steps to link two pit stages together:

-

Click on the pit stage to which you want to assign a dependent (successive) pit stage.

-

Click on the white circle that has appeared.

-

Drag the arrow all the way to the circle on the pit stage that you want to be the next one in order.

-

Release the mouse. The dependency will be created.

Note: The arrowhead always points to the dependent pit stage.

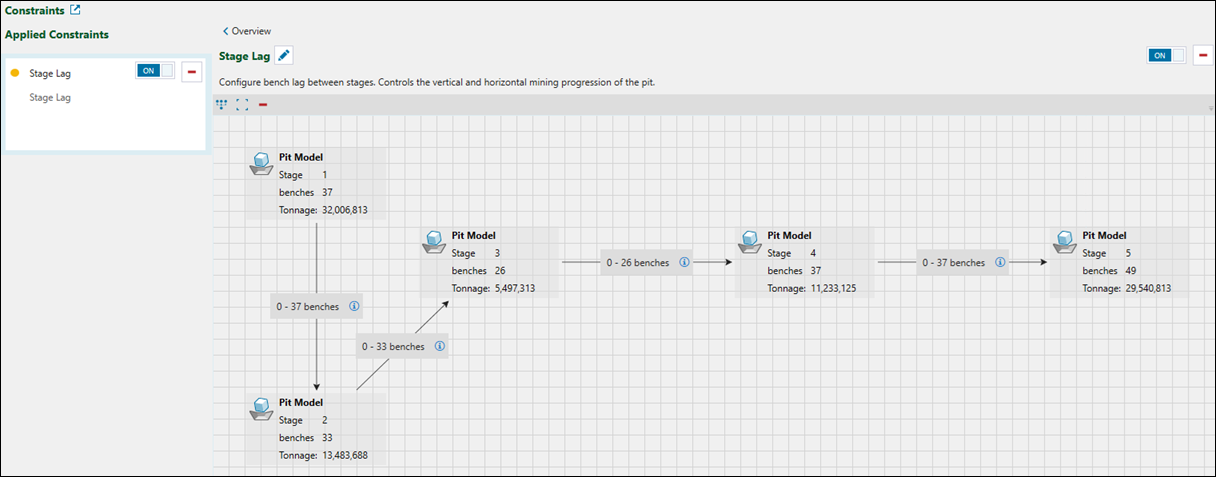

As shown in the image below, each pit stage is represented by a separate node on the canvas that displays the stage number, total contained tonnage, and the number of benches within that stage.

When you first create dependencies between the stages, Evolution will apply the minimum stage lag between them as 0, and the maximum stage lag according to the number of benches of the preceding stage.

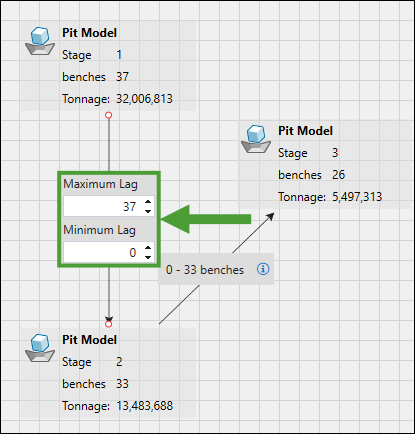

For example, as shown above, Stage 1 of the Pit Model consists of 37 benches, so the range of 0–37 benches is reflected between Stage 1 and Stage 2. To change the default lag settings, double-click the arrow that links the two stages and set the required minimum and maximum lag.

As shown in the image below, if you set the minimum lag to

1, and the maximum lag to 2 between the leading stage (Stage A) and the following stage (Stage B), Evolution will maintain the minimum difference of one bench between these stages and there will never be a bench being mined in the leading stage that is more than two benches below the following stage at that time.