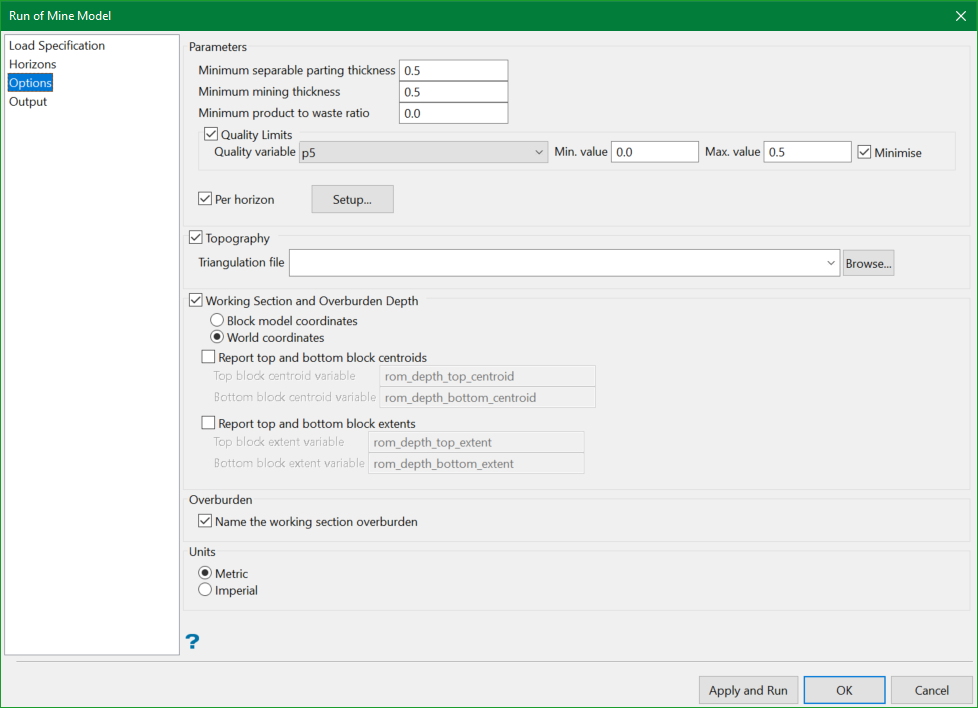

Options

Parameters

This section defines the Run of Mine parameters to be used. The run of mine model is constructed from the geological model using four rules. These rules are applied to the mine modelling process in the following order:

-

Minimum parting thickness

-

Minimum mining thickness

-

Minimum product to waste ratio

-

Quality Limits

Minimum separable parting thickness

Enter the Minimum separable parting thickness. Any waste material between seams less than this thickness is mined with the next seam. This results in composited seams.

Waste material becomes a parting in the composited seam.

The assumption when using this option is that burden material less than this thickness cannot be separated in the pit, so it is mined with the product. However, compositing only takes place if the Minimum product to waste ratio is met.

Minimum mining thickness

Enter the Minimum mining thickness. Any horizon less than this thickness is not mined by itself.

Minimum product to waste ratio

Enter the Minimum product to waste ratio. The total product to total waste ratio in a working section must be greater than or equal to this ratio. Total waste is defined as all in-seam partings plus all between-seam parting.

The tool first looks into the first three parameters to find a seam or sequence of seams/plies that satisfy these parameters in the following sequence of actions:

-

Find the contiguous sequence of plies that contains partings thinner than the given parting thickness. This sequence will be the working section for the part of the block column associated with the given seam.

-

Ensure that the sequence found satisfies the given minimum mining sequence.

-

Ensure that the product to waste ratio is above the specified ratio.

If conditions 2 and 3 are satisfied, the sequence found in 1 is marked as a working section.

Quality Limits

Note: If the quality variable range is not given, the processing remains the same as the previous rules.

However, if the quality limits are supplied, the following sequence of actions is performed:

-

Find the contiguous sequence of plies that contains partings thinner than the given parting thickness. This sequence will be the working section for the part of the block column associated with the given seam.

-

Within the found sequence, detect the largest contiguous subsequence that satisfies the quality variable constraints. This newly found subsequence becomes the potential working section.

-

Ensure that sequence found satisfies the given minimum mining sequence.

-

Ensure that product to waste ratio is above the specified ratio.

Within the given range of the quality variables, the working section can be sought with either maximum or minimum possible value. This is controlled by the Minimise option.

*.rom_parameters) in the Load Specification panel is specified. This specification provides the values for the burden and partings included into the working section. Usually these are supplied as per seam/ply.Per Horizon

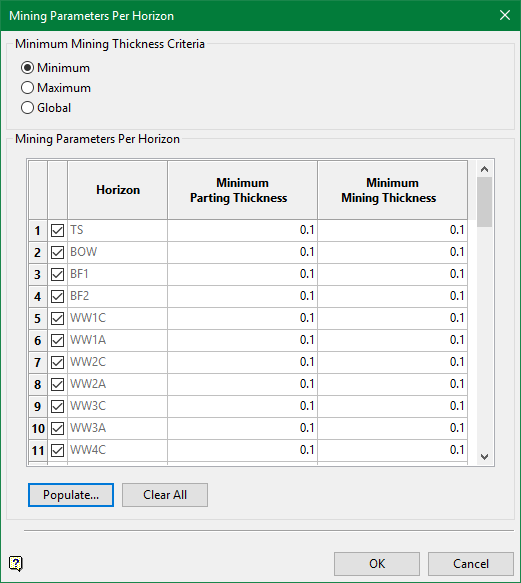

Check this option to define customised parameters for each horizon. Click the Setup button and the Mining Parameters Per Horizon panel shows up.

Minimum Mining Thickness Criteria

The application of Minimum mining thickness during construction of the working section can be further customised by selecting either of the following values:

-

Minimum: Uses the minimum value of all horizon parameters

-

Maximum: Uses the maximum value of all horizon parameters

-

Global: Uses the global value

Mining Parameters Per Horizon

The values of the mining parameters can be entered manually by clicking on the corresponding grid.

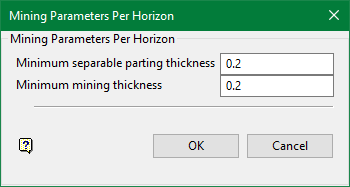

Alternatively, the entire table can be prefilled with specific values using the Populate button.

Enter values for the minimum parting and minimum mining thickness and press OK. The table gets populated with these specific values and if you want to make changes to some values, you can always do that manually.

To reset the values to zero, use Clear All button. This clears all the fields except Horizon and the checkbox column.

Topography

Check Topography to define a triangulation surface representing topography. If this option is used, depths to individual HARP blocks relative to this surface may be written to the output run of mine HARP model. This could be applicable when:

-

Reserves need to be differentiated according to total depth of cover.

-

Reserves should be broken down into depth range.

Note: If no topography surface is used then the depths will be calculated from the top of the block model.

Working section and overburden depth

Check Working section and overburden depth to store calculated depths into new HARP model variables in the resulting run of mine model. Depths may be saved two ways:

-

Block model coordinates are distances relative to a block model origin.

-

World coordinates are real-world coordinate values.

Check Report top and bottom blocks centroids to save the top and bottom centroid values for resultant working sections. Enter variable names to create variables in the resulting run of mine model which will hold centroid values.

Check Report top and bottom blocks extents to save the maximum block extents for the working section. This would be the measurement from the top of the highest block in a working section to the base of the lowest. Enter variable names to create variables in the resulting run of mine model which will hold extent values.

Overburden

Check this option to name resultant burden intervals between working sections after the underlying working section. If this option is not checked, all burden intervals will be named bd.

Units

Select whether the data is in Metric or Imperial units. These come into effect if the Ton Wt check box was enabled in Grid Calc > Integrated Stratigraphic Modelling > Quality and Mining Parameters. See Quality. This is because the imperial system uses feet for thickness measurements and cubic yards for volumetric measurements.

Related topics