Resource Definitions

Use the ![]() Resource Definitions tab to set resource parameters and configure mills and stockpiles by setting either their productivity rate or entering their target accumulation value for the amount of the processed material in a given period.

Resource Definitions tab to set resource parameters and configure mills and stockpiles by setting either their productivity rate or entering their target accumulation value for the amount of the processed material in a given period.

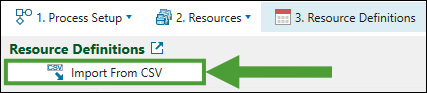

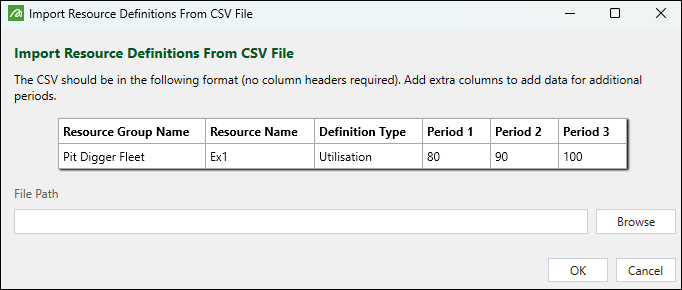

You can either enter the data into the Resource Definitions table manually or import your data from a comma-separated values (.csv) file.

To import the data, click the ![]() Import From CSV button.

Import From CSV button.

Next, in the Import Resource Definitions From CSV File panel, click Browse to select the required file (formatted as shown in the example), and then click OK to confirm your selection.

The data will be imported into the ![]() Resource Definitions tab.

Resource Definitions tab.

Resource parameters

Each resource group has a specific set of parameters that have a said value over defined time frames (periods in your setup).

The following table displays a description of each available resource parameter:

| Resource parameter | Resource groups | Definition |

|---|---|---|

| Utilisation | Diggers, Trucks, Drills, and items in the Custom Resource Groups |

Refers to the amount of time a resource item is used during production. When you define the utilisation between Note: If you set the Utilisation to a value greater than |

| Availability | Diggers, Trucks, Drills, and items in the Custom Resource Group |

The amount of time a resource item is able to be used during production. When you define the availability between Note: If you set the Availability to a value greater than |

| Productivity Adjustment Factor (rate) | Diggers | Indicates that different diggers have different productivity rates. Use the Productivity Adjustment Factor to calculate the Operating Factor (rates). You can set productivity rates using either the Productivity Adjustment Factor or the |

| Combined Utilisation | Diggers, Trucks, Drills, and items in the Custom Resource Group | Calculated by Evolution by multiplying the Availability by the Utilisation. For Digger items, the Operating Factor is further modified by multiplying the Utilisation and Availability by the Productivity Adjustment Factor. |

| Working Hours | Diggers, Trucks, Drills, and items in the Custom Resource Group |

Calculated by Evolution by multiplying the Availability by the Utilisation and total number of hours in the period. Note: For diggers, Evolution also takes the Productivity Adjustment Factor into account when calculating working hours in a period. Therefore, the Working Hours parameter is calculated by multiplying the Availability by the Utilisation, Productivity Adjustment Factor, and total number of hours in the period. |

| Minimum Productivity | Diggers | The minimum productivity rate that a resource item can work at. |

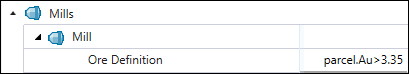

| Ore Definition |

Mills, Stockpiles Note: Overflow stockpiles do not have their own ore definition and use the ore definition of their associated mill. |

States the criteria of material that can be processed by a mill or stockpile. You must enter an equation, usually referring to parcels. According to the example definition below, parcels containing gold with grade above 3.35 will be sent to a given destination. See Formulas and Scripts for more information.

|

| Waste definition | Virtual Waste Dumps |

States the criteria of material sent to a waste site. You must write it in a script in the Default Definition field as an equation, usually referring to parcels. See Formulas and Scripts for more information.

|

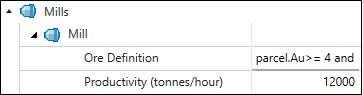

| Productivity (tonnes/hour) | Mills, Stockpiles (including Overflow Stockpiles) when Accumulation mode is disabled. |

Note: You must specify the per-period productivity only if the Accumulation mode is not enabled. If you have the Accumulation mode enabled, you must set the target material accumulation for each period. See Accumulation mode for more information. For each mill and stockpile in a setup, you have to set the Productivity to dictate the amount of tonnes (per hour) that a given mill or stockpile is able to process. If the productivity of the equipment transferring material from the pit is greater than the set productivity, the material will be split between the mill (at the mill productivity rate) and the mill overflow (at the equipment productivity rate minus the mill productivity rate). If the mill overflow capacity does not allow splitting the material, the remainder will go to other destinations. In a different scenario, if the material is not being sent to destinations based on parcel type, and the productivity of the equipment transferring material from the pit to the mill is less than the mill productivity, all material is expected to be sent to the mill in the absence of parcel-based rules. In this case, material will be sent to the mill at the equipment productivity rate that you can set in the

|

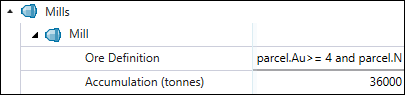

| Accumulation (tonnes) | Mills, Stockpiles (including Overflow Stockpiles) when Accumulation mode is enabled. |

While the Epoch module primarily works on rates (for example, tonnes per hour and volume per hour), you can also set the target material accumulation for each mill and stockpile on a per-period basis in your setup. To do so, you need to enable the Accumulation mode while creating or editing your Epoch setup settings (see Create a Setup for more information).

Note: If you haven’t enabled the Accumulation mode or if you choose to disable it, you must specify the per-period productivity rate for each mill and stockpile in your setup. See Productivity (tonnes/hour) above for more information. |

See also: Resource Groups