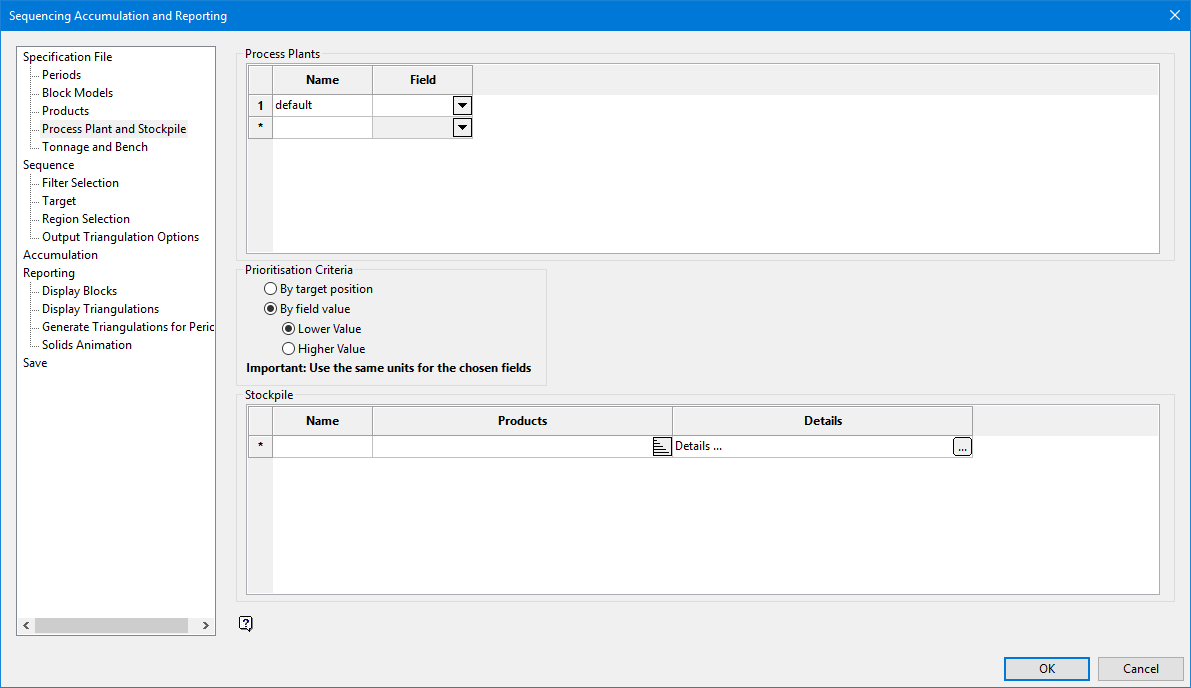

Sequencing Accumulation and Reporting

Process Plant

Use the Process Plant option to work with two or more process plants with different field restrictions.

Prerequisites

Before working in this option, it is recommended you first use the Block Models option to select a block model

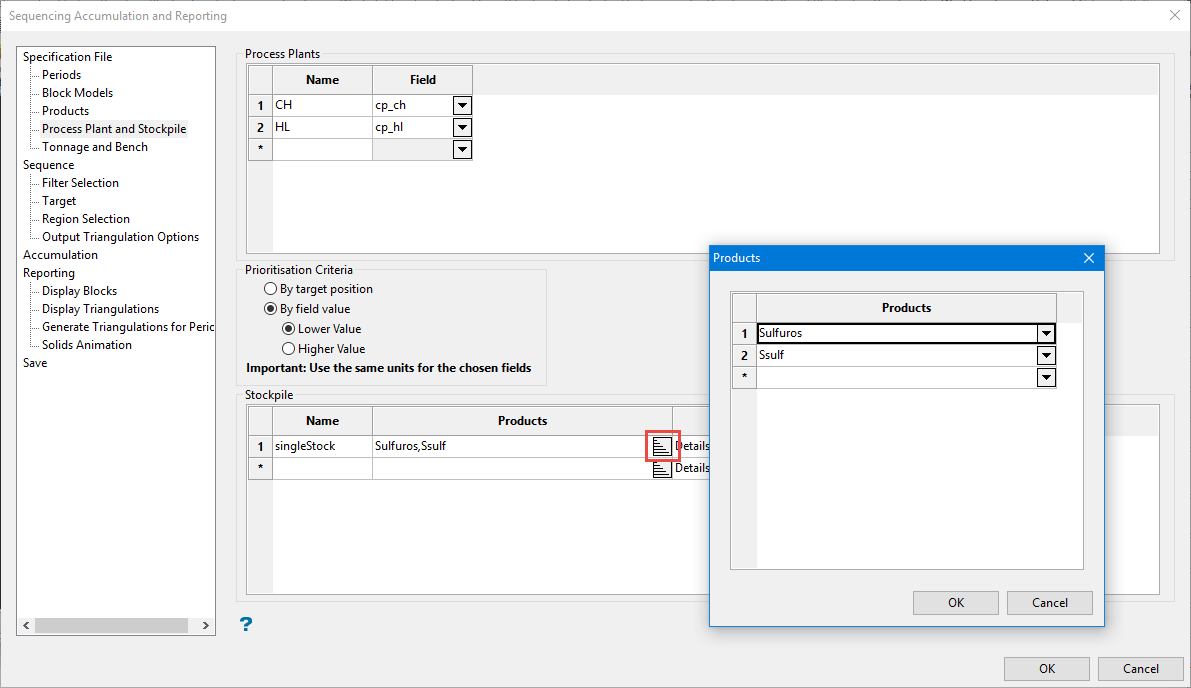

Process Plants

Name

Enter the product code.

Field

Select the block model variable associated with the product code.

Prioritisation Criteria

Select this option to create and use a stock of the type of material selected.

By target position

Select this check box to limit the maximum amount of tonnage that can be used in each period per stock. You will also need to specify the maximum amount of Tonnage per stock that will be allowed.

By field value

Select this check box to set the maximum tonnage extraction allowed per period.

Stockpile table

Name

Enter a code name for the product.

Products

Click the icon to display the Products panel. Use the drop-down list to select each products that will be used in the stockpile calculation. The list is populated from the table at the top of the Products pane.

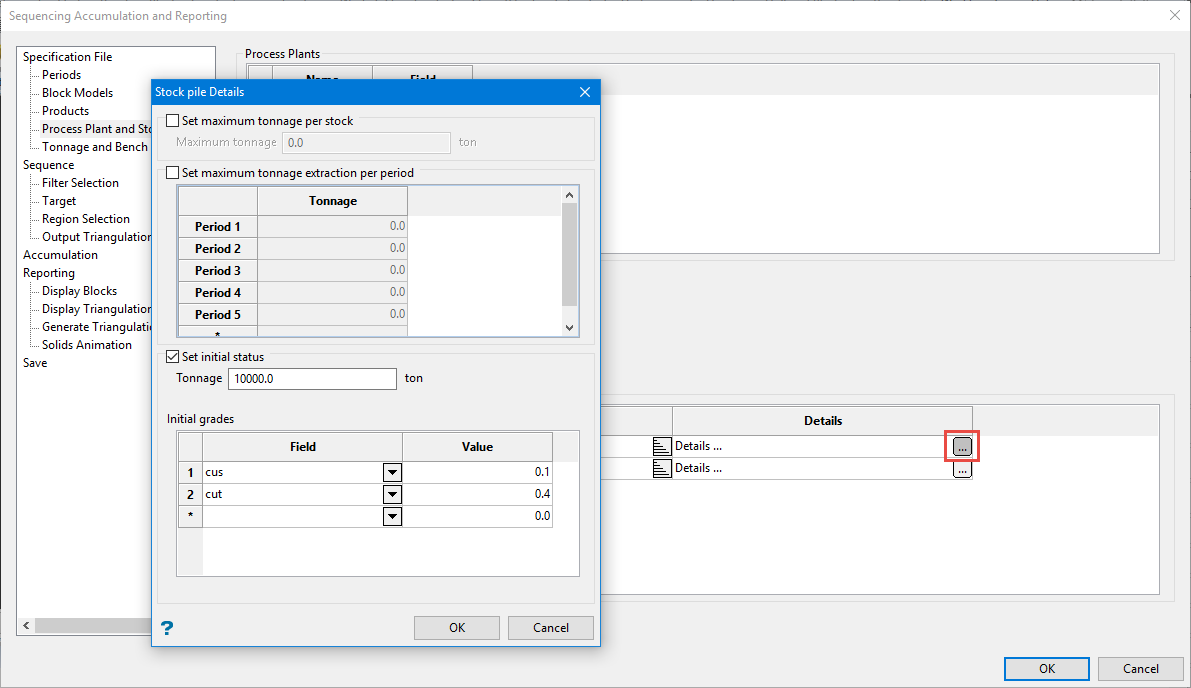

Details

Click the icon to display the Stockpile Details panel. Use this to give additional details about the stockpile.

Set maximum tonnage per stock

Select this option to set the threshold for the maximum tonnage per stock.

Set maximum tonnage extraction per period

Select this option to set the threshold for the maximum tonnage per period.

Set initial status

Use this to set the initial value of the tonnage.

Initial grades

Select the product from the drop-down list, then set the initial grade value.

Click OK to return to the main panel.

Related topics

-

Sequence