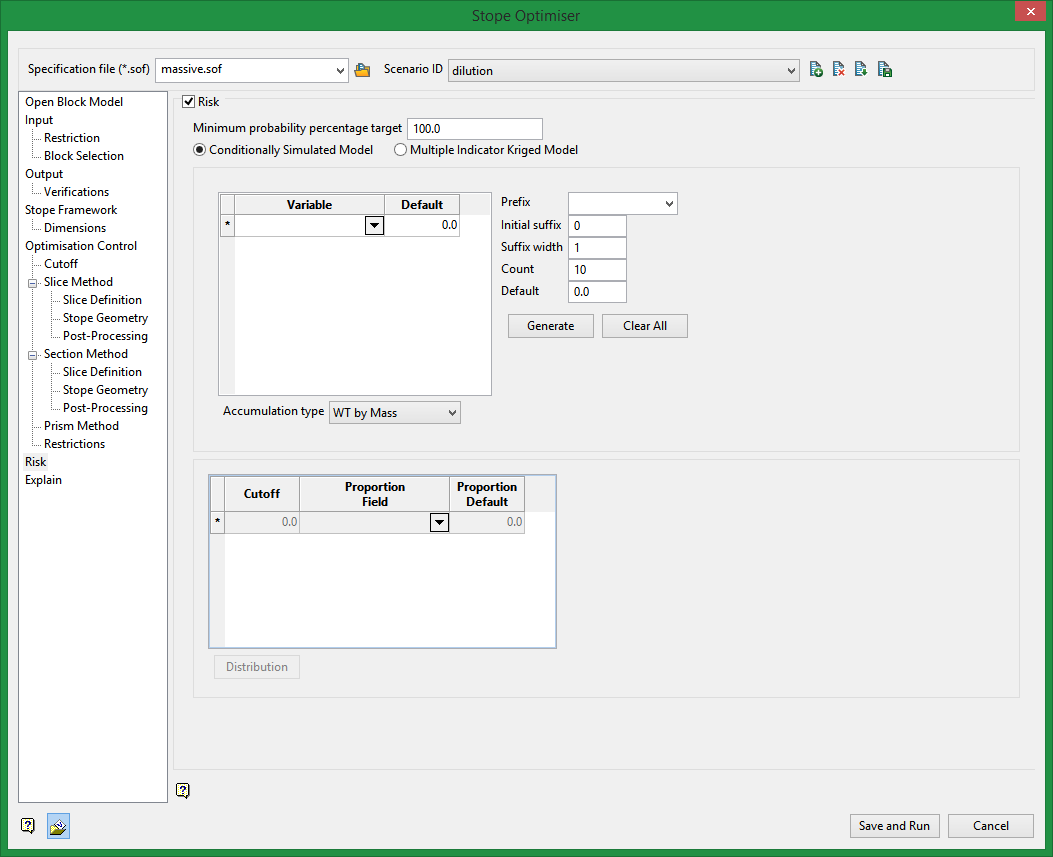

Risk

Instructions

On the Underground menu, point to Analyse, click Stope Optimiser, and then select Risk from the tree menu on the left.

Risk

The most common method of defining geological risk is to simulate the uncertainty associated with estimation of grade into a model cell. There are two geostatistical methods currently handled by the SSO. They are Conditional Simulation or Multiple Indicator Kriging. The SSO geological risk techniques enable either stope-shapes to be designed to a geological confidence level (i.e. maximising optimisation field value while meeting confidence criteria) or evaluated to ascertain their geological confidence level (maximising optimisation field value and reporting the confidence level).

Minimum probability percentage target

The single set of stope-shapes that return maximum value is reported at the requested level of confidence, rather than reporting a stope optimisation on each and every realisation. At 100% confidence the stope-shape will satisfy the cut-off value for every realisation. At 80% confidence the stope-shape will satisfy the cut-off in 80% of the realisations. The trade-off between risk and return is found by graphing the stope tonnage and value against confidence, and is a way to generate a "nested" set of stopes.

Conditionally Simulated Model

The Conditional Simulation method typically provides 20-50 equi-probable realisations of the cell grades within the block model. The maximum number of realisations is currently 50.

If making comparisons regarding the appropriate number of realisations, it should be noted that if alternate models are used, they must have the same starting seed position. It is therefore preferable when making such comparisons that the model with largest number of realisations is used and other sub-sets extracted in lowest sequential order to make correct comparisons.

Multiple Indicator Kriged Model

The Multiple Indicator Kriged (MIK) method provides the frequency distribution of the grades in a block (expressed as the percentage of material above cut-off and the head-grade of this material for typically 10-20 cut-off values), but is not able to identify the location of the grades. The SSO internally manipulates the MIK model to produce “conditional simulation like” outputs using a technique called Pfield Simulation, which is documented in the Stanford University GSLIB package ( http://www.gslib.com ).

Variable

Select the optimisation field that the primary grade field is reported from.

Default

Enter a default value for a single run.

For multiple iterations:

Prefix

Select a prefix.

Initial suffix

Enter the initial digit that the following suffixes will start from.

Suffix width

Enter the number of numeric place holders that the suffix will use.

Count

Enter the total number of iterations.

Default

Enter a default value.

Generate

Click to generate the list.

Clear All

Clears all entries in the table.

Accumulation type

Select between weight by mass, weight by volume, and sum.

Cutoff

Select a cutoff grade. MIK will provide a distribution of grades in a block above this value.

Proportion Field

Select the block model field that holds the grade.

Proportion Default

Enter a default value.

Distribution

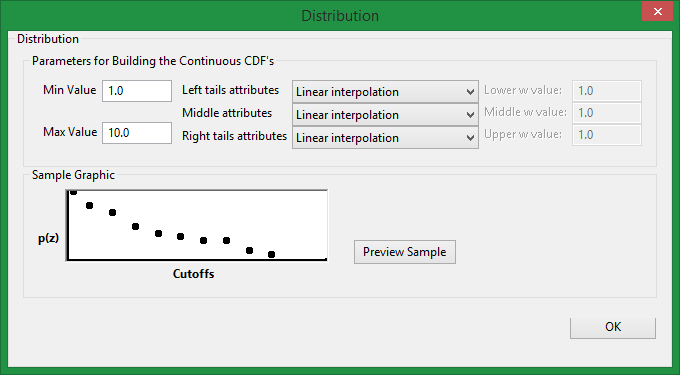

Click this button to display the Distribution panel.

Min Value

Minimum data value allowed.

Max Value

Maximum data value allowed

Left tail, Middle, and Right tail attributes

Select the power model interpolation.

Lower, Middle, and Upper w value

These are values which control the interpolation / extrapolation between the distribution points. The distribution which you provide to the program is discrete (some finite number of bins). The program has to change that into a continuous distribution so it has to interpolate / extrapolate somehow. It uses a power function to do that, and w is the power. If w is 1.0, it is linear.

Related Topics

Section Method Slice Definition

Section Method Post Processing